Report on Redeveloping Railway Tunnels

The renovation and maintenance of old transport tunnels has become increasingly more important in the course of the last few decades. Compared with actually building a new tunnel as such engineers find themselves facing major challenges owing to the fact that rail services must be kept running. As a consequence a Working Group on “Tunnel Redevelopment” was formed under the aegis of the STUVA to provide impulses and recommendations. It started its work in early 2010. The following report is devoted to the progress attained and reflects the outcome of the deliberations.

1 Background and Aims of the Working Group

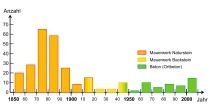

The Working Group on “Tunnel Redevelopment” was prompted by the findings obtained from carrying out the first 2 projects concerned with enlarging the cross-sections of old railway tunnels whilst train services continued to operate. The tunnels concerned were the Mausenmühlen and Jährod on the Nahe route between Bingen and Saarbrücken (Fig. 1). Towards this end the DB AG developed a completely new method for tunnel renovation. This provided for the first time a solution whereby the tunnel is renovated on a 24 hour basis while train services continue to operate at the same time. The construction method was patented together with equipment for putting the procedure into practice [1]. The 2 projects have shown that the possibilities offered by the method are still far from being exhausted so that further developments are still possible in many cases.

The findings obtained are intended to provide the basis for analysing and more closely scrutinising further improvements. This on the one hand is designed to create a high degree of mechanisation for redevelopment activities and on the other to prepare planners and industry for the nature and extent of the volume of tunnel renovation that is anticipated. For this purpose the companies involved in the construction and planning of the 2 projects mentioned participated in the Working Group’s consultations and technical discussions. It ultimately emerged by dint of pertinent queries and intensive process engineering considerations that the construction method applied for both projects could also be used outside of Germany. As a result apart from the DB AG the railway companies of Austria and Switzerland whose tunnel redevelopment requirements are also high are also included in the Working Group’s activities. According to the latest statistical survey undertaken by the STUVA [2] there is a need for the renewal or cross-sectional enlargement of at least 20 km of railway tunnels in Germany alone.

In Switzerland the tunnel renovations needed during the next 10 years were compiled in a SBB tunnel concept. Altogether this means that accordingly 104 km is to be redeveloped. This takes into account individual measures for the vault by way of extensive structural renovation right up to building a new tunnel involving optimal route alignment.

Swiss private railways also wish to tackle maintenance projects as well as renewing safety technical installations. An example of this is the intended production of a new parallel bore for the Albula Tunnel for the Rhaetian Railway. The existing tunnel can then be used for evacuation purposes.

Following investigations and extensive analyses of the situation the Working Group decided to tackle the following main topics:

• The defining of framework conditions for tunnel redevelopments and renovations divided into: while train services are operating, restricted services or no services at all. As far as the work without train services are concerned a distinction is drawn between partial and total closure.

• Tunnel renovations with enlargement of the cross-section as well as possibilities for the subsequent installation of a base invert.

• Description of frequently recurring problem complexes during the redevelopment of old tunnels depending on the type of support, as e.g. natural stone, brickwork, exposed rock.

• Minimum requirements for renovation given running train services relating to the nature and stability of the surrounding rock as well as the state of the structure.

• Compilation of a representative selection of already executed tunnel renovation and refurbishing methods and pointers for applying solutions to future projects.

• Collation of technical and operational framework conditions in the countries Germany, Austria and Switzerland (D-A-CH) to bring about standardised methods in these countries.

• Drawing up an overview of the regulations to be observed in the 3 countries involved.

• Preview of the technical developments to be expected in tunnel redevelopment and renewal in the years ahead.

• Summary of the results in a manual for tendering and planning.

2 Basic Conditions for Tunnel Redevelopments

The term “Tunnel Redevelopment” can signify a large number of different measures. The spectrum of the redevelopment work starts with improving the superstructure by installing a solid slab track, a mass-spring system or a ballast bed adhesive. As far as the vault is concerned this can range from redeveloping sections of the tunnel lining to avoid spalling right up to enlarging the cross-section in individual sections of the clearance profile by removing masonry or lowering the floor. In this connection a new base invert with or without a solid slab track can be installed. Furthermore tunnel redevelopment can entail repointing the masonry or replacing the masonry, installing concrete seals, placing shotcrete as well as anchoring the old vault. Shotcrete ribs installed or backfill injected between the vault masonry and the surrounding rock can be required to stabilise the tunnel.

The construction methods and processes applied for the redevelopment, renovation or enlargement of old tunnels are extremely varied. In addition to the technical requirements decisive for the choice of a suitable construction method are the interruptions to train services through necessary track closures during the execution of construction. In many cases closure of the rail route even although only for a short time is either completely impossible or can only be accomplished briefly. The available tunnel profile largely determines whether work can progress whilst train services are still running.

In Germany the DB AG is obliged on the given data of the EBO (ordinance regulating the construction and operation of the railways) to enlarge the track distance from in some cases only 3.5 m hitherto to 4.0 m for new and extensive upgrading projects. Widening the track distance results in part in protracted construction measures, which can be made even more difficult by having to renew the floor. As a result the so-called tunnel-in-tunnel (TIT) method was applied for the first time when redeveloping the Jährod and Mausenmühlen tunnels [3].

When renovating tunnel structures in excess of 1,000 m the new tunnel must be produced with 2 bores for such total redevelopments or renovations to comply with the regulations now laid down in the valid safety guidelines. This signifies the construction of a new single-track bore parallel to the existing one, which must be renewed through transforming it from a twin-track to a single-track tunnel. These 2 tunnels are then connected every 500 m with cross-passages for evacuation purposes.

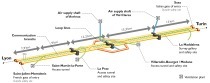

There are also numerous new tunnels being built or planned in Austria as well. These include some 350 km of mainline tunnels including the Brenner Base Tunnel with a total driven length of roughly 110 km. Redevelopment measures devised to improve the substance such as in the Arlberg Tunnel (Fig. 2) or the Tauern Tunnel also take place against the background of improving safety technology. The measures to enhance “Tunnel Safety” were triggered some 10 years ago – owing to the fire incidents in the Mont Blanc road tunnel (March 1999), in the Tauern motorway tunnel (May 1999) and in the Channel Tunnel (November 1996).

Austria’s regulations designed to protect the workforce represent a further source for modifying and partial redevelopment of old tunnels.

In Switzerland the floor is frequently renovated on account of damage resulting from drainage and heaving rock formations, in many cases also in conjunction with lowering the floor to adjust the cross-section for future piggyback transportation. In the case of twin-track tunnels it is also necessary to install a ballast retention system to secure the operational track if the tunnel is toremain in service quite apart from the complex process of underpinning the tunnel vault abutment.

3 Technical Processes and Methods for Redeveloping and Renovating Tunnel Vaults

In recent years mechanised systems have been developed, which combine several working steps. Thus there are combinations for securing and excavating during vault enlargements or for excavating and mucking while working on the floor. For these various solutions apart from the factor of economy the required flexibility during the tunnelling operations plays a decisive role so that unforeseen disturbances during the construction cycle can be reacted to.

Table 1 presents the essential measures during work on the vault in conjunction with the operating conditions. In this connection a distinction is drawn between methods already carried out in practice (green) and future possible fields of application (blue). Currently there is only a slight potential for optimising the fields, which are not coloured.

The classical supporting method, which is used for securing the rock either temporarily as well as long-term, comprises the application of anchors and shotcrete possibly supported by reinforcement mats, support arches or ribs. An anchoring system is also sometimes applied.

In soft ground or in areas with highly fissured, weathered rock normally conventional, advance supporting measures such as grouting and pipe umbrellas, forepoling, lances, freezing or face sealing are applied.

When enlarging a tunnel, support plates can be used to prevent the risk of the old, existing vault collapsing (Fig. 3). As a result in many cases there is no need for advance cuts in conjunction with an anchoring system to secure the vault.

During vault redevelopment operations construction trains are generally used. Protrusions of the masonry affecting the clearance profile are removed by cutting (Fig. 4). The use of construction trains, in the case of which conventional engineering technology mounted on rail wagons is generally applied, is by and large regarded as at an advanced stage of development.

Complete mechanised systems with protective housings, which remove the vault by means of a high-pressure water jet, spray on new inner shells or cut the profile at a given spot, are possible and would facilitate single-track rail services for a period whilst the work was being carried out.

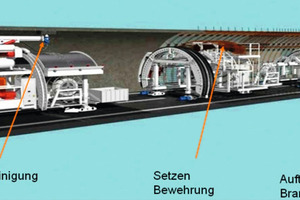

With regard to complying with the fire protection regulations in road tunnels the Herrenknecht AG has developed a system by means of which the tunnel shell can be redeveloped (Fig. 5). The machine concept is split up into 3 main units.

The old vault shell is cleaned and partly removed by a water jet, which generates pressure of up to 1,400 bar. Once the reinforcement is installed a shotcrete and fire-protective layer is applied for the new tunnel inner shell. All mechanised components are self-propelled, rationally set up and can be used for road and rail tunnels with various tunnel diameters.

In twin-track tunnels vault operations and excavations are possible in the wall area depending on the vault thickness through the application of construction trains on the closed track. Work in the apex zone is associated with difficulties on account of insufficient vault stability or the overhead wire on electrified routes. In the event of tunnel vault stability problems and constricted space conditions there is at present no system that can be unrestrictedly applied, which can achieve an enlargement including the removal of rock without interrupting train services.

The essential advantages of a tunnel redevelopment project, during which one of the two tracks is closed, are to be seen in the fact that no modification of the tracks is needed. The operational track that is actually closed can be used for the logistics for the construction trains. In contrast to this problems arise when securing the vault by installing a partition wall between the tracks and the resultant issue of available space. The need to switch tracks substantially restricts continuous driving.

It is possible to enlarge a railway or road tunnel alternately by setting up a telescopic, radially adjustable cutting arm on a machine assembly suitable either for road or rail. A machine of this type was used in 1990/1991 to remove the masonry in the Hasenberg and Prag Tunnels near Stuttgart (Fig. 6).

From 1982 till 1990, two down-the-hole hammers were applied to remove the high-strength masonry in the Arlberg Tunnel. Both were fitted with a 200 mm core drill and were applied in such a way that the drill holes touched one another at the sides. Nowadays cutters or multirip saws with the subsequent use of hydraulic bits are used for removing the vault when enlarging a tunnel. In future the application of cutters or back-cutting technology on mobile working platforms for loosening or profiling in very hard rock is conceivable.

The TIT method was applied for the first time using a tunnel driving portal to widen the Mausenmühlen Tunnel and the Jährod Tunnel on the non-electrified route along the River Nahe between Bingen and Saarbrücken. Further applications involving tunnel driving portals optimised for the enlargement were also used on the Nahe route for the Frauenberg and Kupferheck Tunnels [4] as well as on the Lahn railway route for the Langenau and Hollrich Tunnels (Fig. 7).

It was possible to avoid caving taking place prematurely in the old vault masonry with the aid of support plates during the excavation and enlargement phase. Thus there was no need for additional anchoring to secure the vault.

The vault was excavated and the backfill removed by means of hydraulic hammers, which were fixed at the side of the machine. Mobile drilling arms that were also attached at the sides made it possible to drill blast holes to loosen the rock. After excavating the rock it was primarily supported from various working platforms on the machine using anchors, reinforcement and shotcrete. Subsequently a profile-free vault formwork car was used to install the in situ inner shell (Fig. 8). It was not necessary to install a base invert when these tunnels were renovated.

4 Summary

It was only possible to present a small portion of the extensive work carried out by the Working Group. In this connection, the special issue of “tunnel” published to coincide with the STUVA Conference ’11 is referred to. The activities of the Working Group for the first time provide an insight of the level of tunnel redevelopments and renewals in the countries Germany, Austria and Switzerland. It is intended to give all those involved in the planning and construction process an understanding of the rail-specific general conditions in addition to technical topics. Furthermore on the basis of a large number of examples of projects the perspectives for further technical developments are listed. The need as such exists and will continue to grow in the years ahead.