Production of high-grade Plates

for Herrenknecht TBMs

Superlatives are commonplace in tunnelling. Records are regularly established at some place or other around the globe. Tubes many kilometres in length penetrate mountain ranges, deep under the earth or just centimetres away from the existing infrastructure in urban areas: man and machine implement tunnelling wherever required. Often tunnel boring machines (TBMs) made by Herrenknecht are the driving force – for more than fifteen years greatly supported by high-grade steels from Dillinger, Europe’s biggest manufacturer of heavy plates, based in the German Saarland.

Large-format, extra thick Plates

for constructing TBMs

A tunnelling machine comprises around 800 00 individual parts, 30 % of which are accounted for by complex prefabricated and preassembled units. Enormous demands are placed on the machines: varying geologies – stable, soft, friable or even heaving soils bearing groundwater, tunnels running beneath estuaries, high overburdens, constricted space conditions or buildings extremely sensitive to settlement on the surface. And every machine is designed especially for what it is meant to accomplish.

The specific requirements of a given project, geology, hydrogeology, on-site construction and customer’s wishes, represent the starting point for selecting the type of machine as well as the individual design of a TBM.

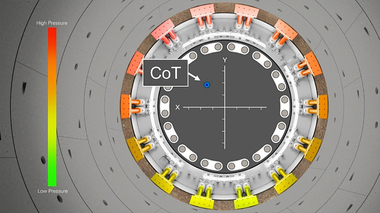

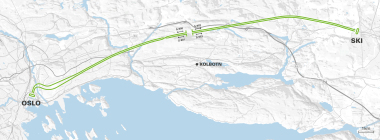

The most important and the forwardmost part of every TBM is the cutter head, known as the cutting wheel in soft soils, whose tools extract the material and remove it within the rear section. Geared to the geology encountered in a specific project, it acts against the face with gigantic driving force in hard rock for instance. Thus for example the double shield TBM cutter heads in the roughly 20 km long twin tubes of the Norwegian Follo Line Tunnel provide several thousand tonnes’ driving force for efficient extraction. In order to cope with such enormous forces, they are almost entirely produced from up to 280 mm thick, large-format high-grade plates made by Dillinger. Furthermore, the four segments of the 7.9 m large cutter wheel welded to form a fully walled monoblock for the Tulfes-Pfons exploratory tunnel at the Brenner Base Tunnel would have been inconceivable without the extra thick and wide plates from Dillingen. “The ratio of width and thickness of the plates from Dillinger is very good”, emphasized Stephan Göggel, the responsible production manager with Herrenknecht in Schwanau. “We need almost exclusively the quality S355 with a thickness of 200 mm – and particularly wide plates to boot in order to save on welding seams”.

Extraordinary width of the plates is also called for when constructing the shield, which possesses practically the same diameter as the cutter head. It protects the main drive and supports the cavity that is produced until it is lined. A shield with a diameter of 15 m is produced and welded from up to nine plates of up to 4.2 m in width and 10 m in length.

Bundled Force

The extremely thick plates produced by Dillinger in large dimensions are also absolutely essential for Herrenknecht for the transmission block, whose size depends on the torque and thrusting forces. The drive and gearbox as a preassembled unit represent the largest and at the same time heaviest part of each machine.

Monoblock housings are characteristic for the gearbox of the Herrenknecht machines. They assure maximum stability for the drive block, which is also specially designed. Many individual motors, which are bundled in a main bearing, generate the torque for the cutter head. So far the record is held by 48 individual motors for the main bearing of the earth pressure balance (EPB) machine, used to build the three-lane M30 city motorway tunnel in Madrid. The cutter head there was driven by a torque of 96 000 kNm. The diameter of this machine, however, was bettered by a TBM with almost 16 m excavated diameter currently being employed to produce the Santa Lucia road tunnel to upgrade the motorway between Florence and Bologna. The cutter head drive installed here is the biggest gearbox provided by Herrenknecht.

All gearbox housings and drive units are built in Schwanau in order to protect the intricate technology. Dillinger supplies the thickest heavy plates (240 mm) to ever appear on the market for producing these heavy monoblock gearbox housings. They are optimally cut in terms of length and width so that the housings weighing a maximum 25 t each can still be handled. For this reason, the plates are procured directly by Stephan Göggel and his team in the component plant. “We are aware when we need certain specifications, what our requirements are and which component parts we have to produce from the plates in question. The choice of possible suppliers is limited particularly for cutter heads and gearbox housings”.

Herrenknecht also builds spacer, bearing and adapter rings, bearings and gaskets itself although it does purchase the hydraulic components. Up to ten rings are required for a drive unit, involving diameter sizes of 3–8 m and weighing up to 15 t each. Dillinger produces the plates for the rings, then they are rolled to a thickness of 120 mm and a width of 400 mm at Herrenknecht. For larger sizes such as these used for the Santa Lucia Tunnel in northern Italy, the tunnelling machine specialist again calls upon the services of Dillinger.

Speedy Reaction

As soon as the TBM design department comes up with the concrete dimensions for the plates, as far as the production manager is concerned the heavy plates cannot be delivered quickly enough. After all, the entire machine is constructed around the gearbox housing so that the progress of the project decisively depends on Dillinger’s supply capability.

“Dillinger supplies us with the heavy plates required for a project within eight to ten weeks. That’s really fast”, Stephan Göggel acknowledges. “The fact that the deadline for delivery is adhered to so reliably, also speaks for Dillinger, for that’s not something necessarily customary in the steel branch”, adds the production manager.

Roughly 80 per cent of the plates are S355J2+N quality steels

according to Herrenknecht works standard with restricted carbon equivalence for good welding properties. The heavy plates guarantee higher impact values than demanded by the norm.

In addition to normal ultra sonic tests, ultra sonic tests of class S3E3 prove in particular cases of deployment that the plates are free of inclusions, contaminants and extensive divisions in the plate centre area. Special products in Z quality – Z15, Z25, Z35 – for stresses in the through-thickness direction given large plates and welding seam thicknesses – are commissioned from Dillinger.

All contour cuts are produced at the component plant in Schwanau, the individual elements assembled, welded, engineered and pre-assembled as a complete gearbox casing. According to Stephan Göggel Dillinger offers the most varied range of plate thicknesses, lengths, widths and qualities. “We require a large number of plates with specifications and high unit weights such as a 220 mm thick plate with a width of 4 m. Here Dillinger occupies a leading position worldwide in continuous casting”. The common pursuit of new records in tunnelling goes on: Herrenknecht’s order books for tunnel boring machines are full. Whether for road transport, rail or metro: all over the world big cities place their trust for expanding their transport arteries in technology from Schwanau coupled with plates from Dillingen.