Innovative TBM-Steering: Advancing Human-Machine Interaction in Tunnelling

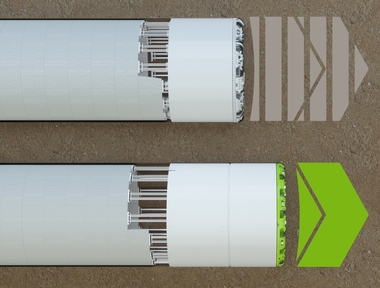

Directional steering of tunnel boring machines (TBMs) is a critical process involving the minimization of horizontal and vertical deviations from a designed tunnel alignment. Traditionally, TBM operators manually controlled the steering process by adjusting thrust cylinder pressures while monitoring the entire tunnelling operation. However, finding qualified personnel for this complex task has become increasingly challenging for construction companies. To address this issue and with that further improve efficiency and safety, Herrenknecht has developed an innovative thrust cylinder control system with a novel human-machine interface (HMI) – the Center of Thrust (CoT) steering system, offering semi-automatic control for active steering actuators and streamlining TBM operation.

The CoT steering system enhances the operator‘s experience by simplifying the steering process. In the semi-automatic mode, operators set CoT coordinates and the desired advance speed via the touch screen

The CoT steering system enhances the operator‘s experience by simplifying the steering process. In the semi-automatic mode, operators set CoT coordinates and the desired advance speed via the touch screen

Credit/Quelle: Herrenknecht

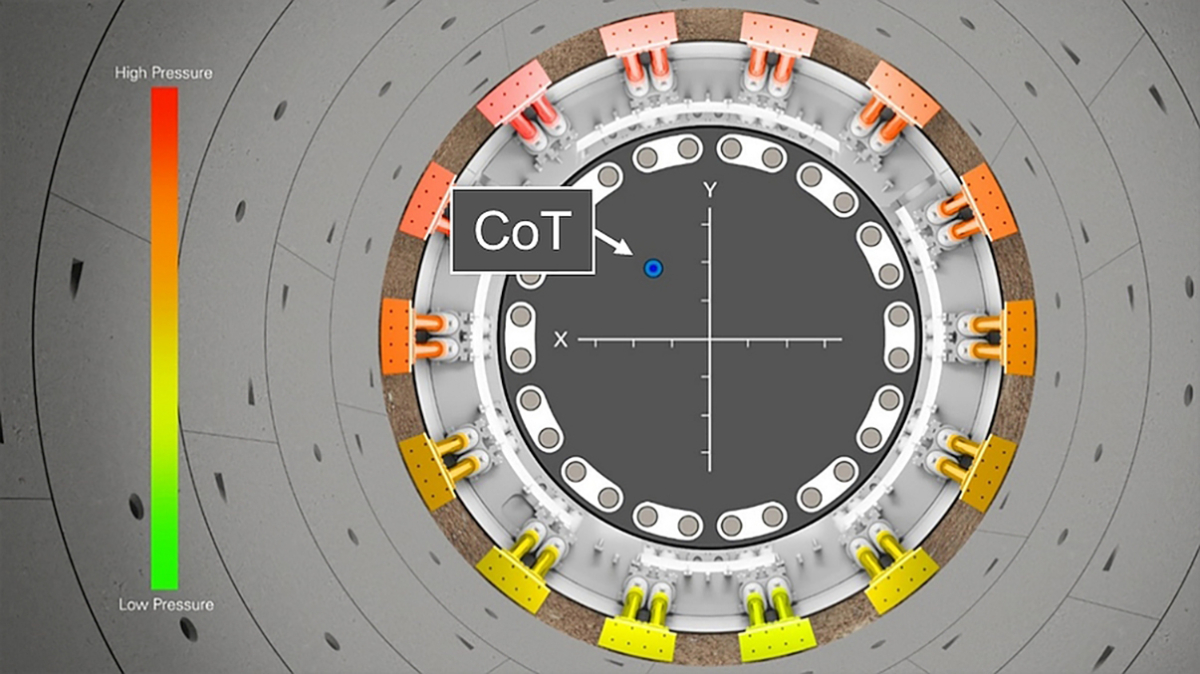

Visualizing the Center of Thrust

The main feature of the CoT steering system is the visualization of the center of thrust, which represents the point of application of the total thrust force generated by all thrust cylinders. Visualized as a dot within an x-y chart, the CoT‘s position reflects the distribution of forces. Operators can adjust the CoT setpoint horizontally or vertically to steer the TBM horizontally or vertically, respectively. The CoT visualization provides operators with a clear understanding of force distribution at any given moment, independent from the number of thrust cylinders and their grouping.

Enhancing the Tunnelling Process

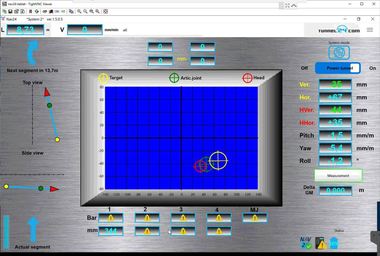

The CoT steering system enhances the operator‘s experience by simplifying the steering process. In the semi-automatic mode, operators set CoT coordinates and the desired advance speed via the touch screen. This innovative interface reduces complexity as only CoT setpoint adjustments are necessary for steering, replacing the need to manually adjust individual thrust cylinder pressures. As a result, more intuitive and precise horizontal and vertical steering becomes easier. Furthermore, the CoT steering system standardizes the human-machine interface, facilitating the training of unexperienced operators and their adaptation to new TBMs. The CoT visualization enables quick comprehension of force distribution, improving decision-making and addressing the demand for highly specialized personnel.

As state-of-the-art Herrenknecht control cabins are equipped with touch screens, the CoT steering system can also be installed as an upgrade to the standard GUI

As state-of-the-art Herrenknecht control cabins are equipped with touch screens, the CoT steering system can also be installed as an upgrade to the standard GUI

Credit/Quelle: Herrenknecht

The technology described is already integrated in the first Herrenknecht TBMs, combining a conventional control panel as well as a graphical user interface (GUI) on a touch screen. The hybrid HMI allows operators to switch easily between the CoT steering mode and manual mode through a GUI menu. The touch screen allows intuitive input of CoT setpoints, enhancing the overall user experience. Based on customer preferences, the HMI input elements can be implemented as hardware push buttons, sliders or joysticks. As state-of-the-art Herrenknecht control cabins are equipped with touch screens, the CoT steering system can alternatively be realized through an upgrade of the standard GUI, which also allows for retrofitting of existing machines.