New Tunnel Channel – presented at the 2013 WTC in Geneva

Experts from the international tunnelling industry will congregate in Geneva from May 31 to June 7, 2013, for the ITA-AITES 2013 World Tunnel Congress and the International Tunnelling and Underground Space Association’s 39th General Assembly. It will be hosted by the Swiss Tunnelling Society, which has invited top-ranking specialists from the tunnelling industry to present lectures and workshops. In addition, international exhibitors will display their latest product developments, ideas and know-how in the field of tunnelling. Against this background, the ACO Company from Rendsburg/D will present a new development.

Tunnel planners and engineers constantly find themselves facing new challenges given the strongly increasing demand for infrastructures in densely populated urban areas and the need to create transport routes on the highway network both on the surface and underground, which are as short and efficient as possible. Towards this end, stepped-up demands on material, furnishings, traffic safety, functionality and of course, the service life of the tunnels have to be taken into consideration.

As far as tunnel drainage systems are concerned, priority is not accorded the removal of water resulting from precipitation at the portal or the splash water caused by vehicles. Instead major importance is attached to the composition and design of drainage systems in a case of emergency. Should an accident occur in the tunnel, combustible and hazardous liquids must also be collected quickly and safety transferred to a closed system so that they are cut off from the oxygen supply. The tunnel drainage system is devised in such a way that it prevents the liquid from spreading thus enabling the emergency services to do their job.

Applying safe Drainage Systems made of Polymer Concrete

Drainage systems and the related minimising of the need for repair and maintenance signify that the channel system must be made from a high-grade material. Now polymer concrete slotted channels are also approved for use in tunnels after the recent publication of the new version 03/12 of the ZTV-ING, Part 5, Tunnelling (Additional Technical Contractual Conditions and Guidelines for Engineering Structures”). In this way, polymer concrete now ranks alongside concrete as a material for application in tunnels.

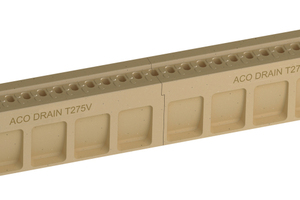

The ACO DRAIN® tunnel channel Monoblock T 275 V thus fulfils the European tunnel guidelines 2004/54/EC, the German guidelines and regulations according to RABT and ZTV-ING. Thanks to ACO`s polymer concrete special mix the channels are rated in the “non-combustible” category. Furthermore they are frost and thawing salt resistant even without additional coatings and possess extremely high resistance to chemicals. With a water penetration depth of 0 mm the material polymer is water impermeable thus making it an ideal material for foundation engineering. The smooth surface allows water and dirt particles to be transferred quickly and can be easily cleaned if required.

The channel elements also possess substantially higher strength values and weigh less than comparable concrete products given a similar density. The low pre-cast section weight of the 2.0 m long elements simplifies handling and installation. Factors which can often play a considerable role for tunnels with constricted space conditions. The channel elements have been designed especially for application in tunnels. Thus the laying concept as practised from above results in a considerable increase in performance. The new side-wall structure and material distribution of the mono-cast construction lead to enhanced bearing capacity and overall stability. Undercut pockets save on material and in turn, weight quite apart from providing improved anchorage to the neighbouring emergency path sector. An integrated storage slot for housing ductwork (DN 40) enables LED control lines to be installed. Lip seals made of ethylene-propylene-diene monomer (EPDM) seal the butt joints of the tunnel channel against liquids.

Surface Design enhances Safety

The channel that is being presented possesses a continuous intake slot in contrast to conventional slotted channels. The channel head is provided with a number of individual slots. Napping on the intermediate divider also increases the roughness of the channel surface. In this way, the safety of wheelchair users when passing over and crossing the channel to reach the emergency pathways is increased particularly in urban tunnels. The same applies to cyclists and bikers. There is no danger of wheels getting stuck on account of long slot apertures. Furthermore the arrangement of several individual slots prevents larger objects (hub caps etc.) from becoming wedged, whereas smaller, flushable parts can be accepted. The structurized surface enhances safety thanks to its vibration effect and also serves to separate the carriageway and emergency pathway optically. Available with kerb heights of 3 and 7 cm in keeping with RABT and ZTV-ING requirements. They can also be supplied with closed slots should this be required. Accessories such as the baffle shaft as transition element, inspection elements and connecting elements round off the ACO drainage system for tunnels.