New Development of a Two-Component Annular Gap Mortar Formula

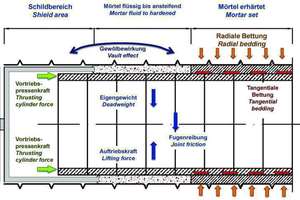

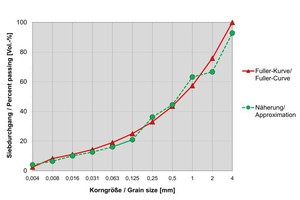

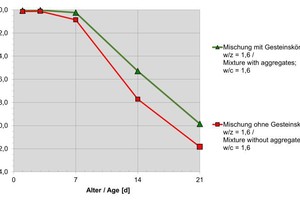

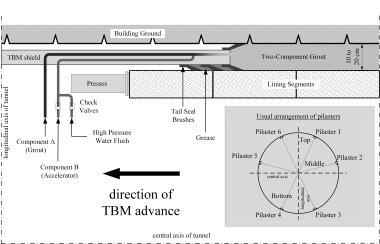

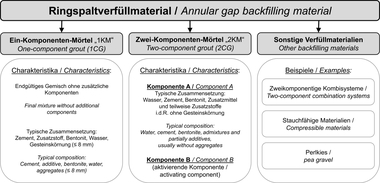

In the case of shield driving with a segmental support and annular gap mortar grouting, lifting forces act on the segment rings once they leave the shield tail. These forces can lead to pronounced misalignments of neighbouring rings, damage to the ring joint and diminished leak tightness. A two-component mortar can be applied to avoid this damage, which reaches the necessary stiffness to support the segments once the components have been mixed in the annular gap. This report deals with the targeted new development and optimization of the mortar. An explicit set of requirements is defined and it is explained how aggregate is used to arrive at an early, stiff bedding for the young segment rings while at the same time saving on accelerator.

1 Introduction and Objective

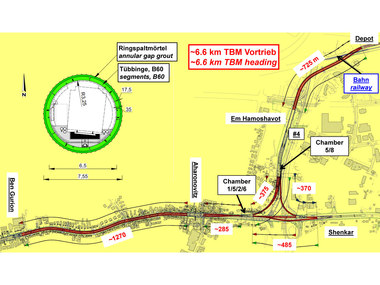

In the case of mechanized tunnelling with shield tunnel boring machines the prevailing ground is excavated by a cutting wheel at the face. The surrounding ground is temporarily supported by the shield jacket and the definitive lining produced in the form of reinforced concrete segments. The annular gap created between the excavation wall and the segmental lining is filled continuously as the machine progresses in order to avoid harmful ground deformations and provide the segment rings with a bedding as stiff as possible. This leads to the planned effect of the...