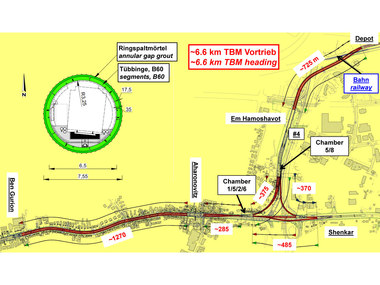

Strength Development of Two-Component Grouts for Annular Gap Grouting

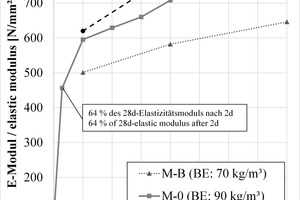

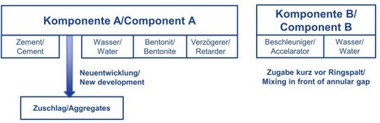

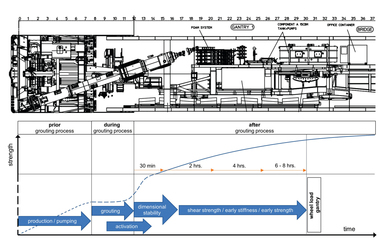

In mechanized tunnelling an early and safe bedding of the last inserted segment rings is a constructive necessity. This can purposefully be achieved by using a two-component mortar as grouting material whose composition is adapted for the geological and structural circumstances. For this purpose, the operating side requires knowledge about possible control parameters based on optimization in terms of material as well as a fundamental understanding of the strength development of a two-component mortar.

1 Introduction and Motivation

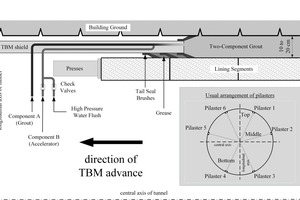

In mechanized tunnelling with segmental lining a cavity emerges during the production of the tunnel between the surrounding soil and the exterior wall of the tunnel with a size of generally 10 to 20 cm [1]. This annular gap must be backfilled using a suitable material in order to reduce surface settlements as well as stabilize the segmental lining appropriately at the same time for ensuring durability and serviceability of the construction.

Thereby a complete filling of the annular gap is necessary. Additionally, the mortar must be able to absorb the operating...

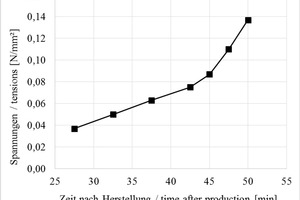

![2 Strength development of a two-component mortar [3]](https://www.tunnel-online.info/imgs/1/3/0/7/7/3/5/tok_d8a5bd16cf82b7e901762d5f5b03dadc/w300_h200_x600_y585_bild02-annular-gap-mortar-rub-26cf94c4293ec866.jpeg)

![5a By means of additional weight adjusted tension [N/mm²]](https://www.tunnel-online.info/imgs/1/3/0/7/7/3/5/tok_64457c3ade3c583dd5de4bc9e6e6acd0/w300_h200_x600_y910_bild05-links-annular-gap-mortar-rub-361f7cad40c0454c.jpeg)