Test Methods for Simulating the Solidification Process of Annular Gap Backfilling Materials

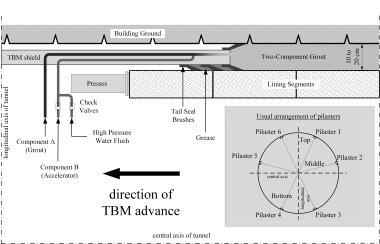

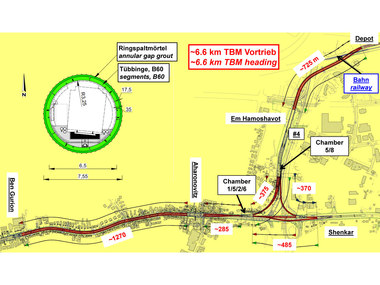

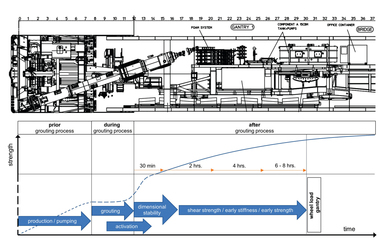

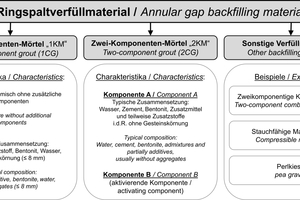

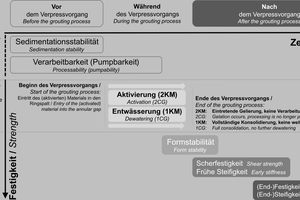

If a tunnel is driven by a TBM, the so-called annular gap remains between the ground and the tunnel lining, which must be filled during the tunnel drive. The essential process for the grouting procedure differs according to the annular gap backfilling material used, depending on the given (hydro-)geological and project-specific boundary conditions. In the case of one-component grouts a dewatering of the grout takes place into the surrounding soil corresponding to its permeability during the pressure-related grouting process. This leads to a consolidation of the grout. In non-permeable or insufficiently permeable soils a solidification process through interaction with the surrounding soil is not possible. In such cases, two-component grouts are used that harden through a chemical reaction between the activator and the cement. In this publication, methods for simulating the solidification process of different annular gap backfilling materials are presented.

1 Introduction

1.1 Necessity of the Annular Gap Backfilling

In mechanized tunnelling a gap remains between the segmental lining and the excavated ground – the annular gap – that must be completely filled with a suitable annular gap backfilling material immediately after installation of the segments. The annular gap backfilling serves for the immediate positive- and force-locking bedding of the installed segment ring. This prevents the tunnel lining from floating as well as from sinking under the load of the TBM’s backup. In addition, the primary stress state of the soil can be largely...

![3 Dewatering process of a one-component grout into the surrounding soil [14]](https://www.tunnel-online.info/imgs/1/5/8/9/3/4/9/tok_63067df66609c87b356b43fb7145047b/w300_h200_x600_y382_03-ringspalt-annular-gap-ruhr-universitaet-bochum-6c9273f5187c3835.jpeg)

![4 Modified filter press test according to DIN 4127 [15]](https://www.tunnel-online.info/imgs/1/5/8/9/3/4/9/tok_cc9298ddc72e2310203f35b951b6b2d8/w300_h200_x600_y501_04-ringspalt-annular-gap-ruhr-universitaet-bochum-3c4e4aecfedc22b3.jpeg)

![5 Total amounts of filtrate water (left) and temporal development of the amount of filtrate water (right) of a semi-active one-component grout depending on the dewatering pressure immediately after production [6]](https://www.tunnel-online.info/imgs/1/5/8/9/3/4/9/tok_e79d1c8e32772e68057f83a6a31c2da0/w300_h200_x600_y273_05-ringspalt-annular-gap-ruhr-universitaet-bochum-b2a1ca3db5a40e81.jpeg)

![6 Total amounts of filtrate water and shear strengths of a semi-active one-component grout depending on the grout thickness immediately after production [6]](https://www.tunnel-online.info/imgs/1/5/8/9/3/4/9/tok_73396908d31018f3262b56c6236e9d5b/w300_h200_x600_y428_06-ringspalt-annular-gap-ruhr-universitaet-bochum-498c4e0ac724a5e1.jpeg)

![7 Left: Shear strengths of a semi-active one-component grout depending on the dewatering pressure immediately after production [6]. Right: Shear strengths in different depths of a dewatered semi-active one-component grout](https://www.tunnel-online.info/imgs/1/5/8/9/3/4/9/tok_62eec37bd2783f797a965277e83485c3/w300_h200_x600_y276_07-ringspalt-annular-gap-ruhr-universitaet-bochum-8198265ef94db91e.jpeg)

![9 Left: Gel times of a typical two-component grout with different amounts of the activator and comparison to the literature (gel time 1: [18]). Right: Shear strength development of a typical two-component grout with different amounts of the activator](https://www.tunnel-online.info/imgs/1/5/8/9/3/4/9/tok_34c5f836f844d94be9c12a19181d0cb4/w300_h200_x600_y275_09-ringspalt-annular-gap-ruhr-universitaet-bochum-4a7ab6b318e83c16.jpeg)