Influence of the reactive Components on Shotcrete Performance

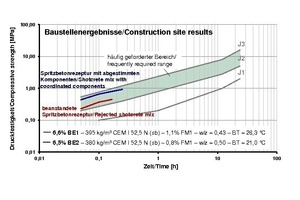

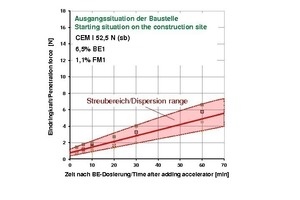

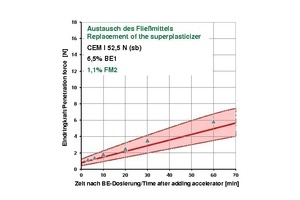

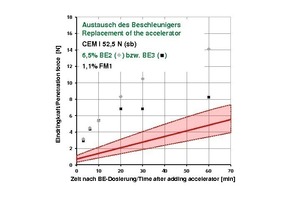

When shotcrete is used in tunnelling, a stable and robust shotcrete system is essential for safe and economical construction. In order to ensure a robust system, the reactive components of the concrete (cement, superplasticizer, accelerator) have to be coordinated. The article describes the Accelerator System Test (German: Beschleuniger-Systemtest BEST), which can be used to coordinate these components. On the Stuttgart–Ulm rail project, the BEST was used successfully to remedy unsatisfactory shotcrete performance.

1 Introduction

The shotcrete method has become established in European tunnelling since the 1960s, and is carried out in the following steps: first, the rock is excavated, for example by blasting, then the exposed surface is supported by spraying shotcrete, if necessary in combination with other measures (reinforcing mesh, rock bolts etc.). Shotcrete in tunnelling is mostly applied by the wet-mix process (Fig. 1), with ready mixed concrete pumped to the nozzle, where accelerator is added. This is intended to provide rapid strength development, particularly when the shotcrete is sprayed...