HeidelbergCement: Development and Application of reactive Shotcrete Cements

120 km of rail tunnels are currently under construction on the Stuttgart–Ulm rail project. Many of these tunnels are being mined according to the New Austrian Tunnelling Method (NATM). But also outside this major project, many more tunnels are under construction in Baden-Württemberg and Bavaria, which also demand high-performance construction materials. With a view to this high demand, HeidelbergCement decided some years ago to develop a shotcrete cement, which is reactive, economical and available in the region. The plant in Schelklingen on the Swabian Alb was selected as the production location since it is near the projects in southern Germany and production optimisation steps can be implemented and controlled especially well at this high-capacity plant. The development steps for the production of a reactive shotcrete cement and in particular the quality assurance measures in the manufacturing plant are described in this article.

Introduction

Tunnelling has a long tradition in Germany. High-speed transport routes with elongated alignments and flat gradients require an underground route. This applies the same for road and rail. Transport tunnels are driven using various construction methods. The construction of tunnels in cut-and-cover is normally the most economic solution. If this method of construction cannot be used, then the tunnel has to be mined below ground, either conventionally according to the NATM (Fig. 1) or with a tunnel boring machine.

This article concentrates on mined tunnelling using shotcrete for excavation support. It describes the development process of reactive shotcrete cement, quality assurance at the Schelklingen production plant and the experience gained with the newly developed cement in the tunnel drives on the Stuttgart–Ulm project and in further tunnels in recent years.

Only an experienced team of laboratory manager, concrete technologists and application technicians working together closely can organise and optimise the development process of the shotcrete cements. Partners from the additives industry, concrete firms and experts from tunnel contractors also make additional valuable contributions in the assessment and optimisation of the cements, concretes and systems.

Shotcrete for Excavation Support

Shotcrete technology already revolutionised tunnelling 150 years ago. It replaced the laborious support of timber props and steel beams and thus extremely accelerated advance rates.

The composition of shotcrete could be further optimised with the developments of chemical additives (admixtures). Modern wet-mix shotcretes, in addition to cement, water and aggregates, may also contain powerful plasticisers, retarders, rock flour, fly ash, fibres and microsilica. Effective accelerators are then added at the nozzle of the shotcrete machine, which wet the concrete evenly so that it starts hardening within a few seconds. This enables shotcrete to be sprayed in great thicknesses and with little rebound onto overhead surfaces. Requirements regarding the early and final strength, density and leaching behaviour are adjusted to suit. The technical further development of more powerful shotcrete machines has also contributed to the success of the shotcrete method.

Wet-mix shotcretes have meanwhile reached such a high quality standard that they could in principle even be used for permanent support. The first research results show that tunnels can be built without inner linings when a heavier shotcrete layer is formed and the rock mass has sufficient stability.

Development of a high-performance Shotcrete Cement

The implementation of the Stuttgart–Ulm rail project was in discussion for years and was repeatedly renegotiated. At the start of 2000, however, the plans became more fixed and it became apparent that the project had a chance of being implemented. The concept is based above all on tunnel solutions in the inner city area of Stuttgart and for the new line from Ulm to Wendlingen.

The overall project includes almost 120 km of tunnels suitable for ICE operation. In the city centre of Stuttgart, the planned tunnels enter a new, deeper station and carry rail traffic below ground out of the valley basin. The tunnels pass beneath high-value building susceptible to settlement with shallow overburden. The alignment from Wendlingen to Ulm has to overcome the hills of the Swabian Alb. The uphill and downhill sections are evened out in long tunnels so that high operating speeds can be maintained.

The firming up of the construction plans for the project posed the challenge for HeidelbergCement to develop construction materials, which can fulfil the requirements of modern tunnelling according to the NATM. The team from HeidelbergCement could also draw on experience from the construction of the 2350 m long Engelberg Base Tunnel near Leonberg, which was built between 1995 and 1999. In this road tunnel with extreme excavation sections, it was already clear that tunnelling according to the NATM poses great challenges for building materials and construction.

The Schelklingen plant of the HeidelbergCement AG lies in the Urdonautal between Ulm and Ehingen (Fig. 2). Various clinkers are fired there, which are ideally suited for the production of standard and special cements. The raw materials are limestone and lime marl from the nearby quarry in Vohenbronn (Fig. 3) as well as sand and iron ore to optimise the composition. The targeted extraction of the raw materials and homogenisation of the material flows in the entire process guarantee a very uniform quality of the cements.

The carefully selected starting materials (raw flour and correction substances) are burnt to clinker in rotary kilns and stored temporarily in large silos. With the addition of a matched sulphate source, the cement is ground until prescribed grading bands and finesses are reached. The grinding is continuously controlled and ensures the uniform quality of the shotcrete cements. The ground cement is withdrawn through a sifter and stored in end product silos.

For the production of the shotcrete cement CEM I 52,5 N (sb), a reactive high-value clinker is used. The phase composition of this clinker is shown in Table 1. The clinker is ground in two specially selected ball mills, which are especially suited for fine cements.

Sulphate is generally added to cement grinding in order to block the spontaneous reaction of the clinker phase C3A and thus regulate the hardening behaviour of the cement. The sulphate source retards the hardening process and thus prolongs the workability time. The usual sources of sulphate are gypsum (dihydrate, CaSO4 x 2 H2O) and anhydrite (CaSO4), added in a suitable adjusted ratio. The gypsum can dewater to hemihydrate CaSO4 x ½ H2O with appropriate control of the grinding process. For shotcrete cements, the composition of the sulphate source (ratio of dihydrate to anhydrite) differs considerably from the composition of other cements. For the shotcrete cement CEM I 52,5 N (sb), the ratio of dihydrate to anhydrite is clearly shifted toward anhydrite.

Too much anhydrite content in shotcrete cements can however impair the workability properties of wet-mix shotcrete. The concrete can stiffen rapidly and harden before spraying. It is therefore important to detect the properties early and take countermeasures if appropriate. For this reason additional tests are carried out daily in the cement laboratory in Schelklingen as part of the extended internal production control. In addition to the determination of the water demand, the heat development of the cement after 10 minutes is also checked, using a quick test. The temperature rise should be in the range 20 ± 5 K. 35 % has been internally specified as the upper threshold for the water demand of the CEM I 52,5 N (sb). If the stated tolerance limit is reached, the sulphate source composition and/or the fineness of the cement may have to be adjusted.

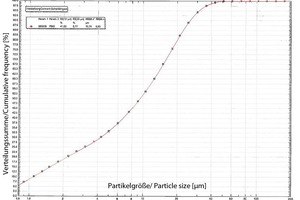

Table 2 shows the essential quality data for the shotcrete cement CEM I 52,5 N (sb), and Fig. 4 shows the grading distribution of CEM I 52,5 N (sb).

Test Procedure to control the Reactivity of Shotcrete

In the course of the production process, continuous standard tests are performed in the cement laboratory at the Schelklingen plant; these ensure the maintenance of the set target values and guarantee the homogeneity of the cement. The standard tests, however, do not make any statements about the basic reactivity of the cement and its special suitability for a shotcrete system (cement in combination with reactive accelerators). For this purpose, further tests are necessary.

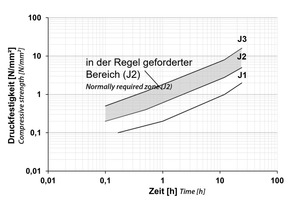

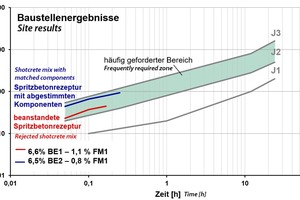

There are various test procedures to evaluate the reactivity of shotcrete systems, for example the laboratory spraying test, which involves making test samples of shotcrete (shotcrete boxes), on which the strength development of the accelerated concrete is determined. Shotcrete is classified up to a concrete age of 24 hours according to its strength development into the early strength classes J1, J2 or J3 according to DIN EN 14487-1:2006-03 (Fig. 5). The laboratory spraying test and the evaluation or assignment of the strengths is however expensive in personnel and time and thus less suitable for the continuous checking and control of running production.

The Engineering & Innovation (E&I) department of HeidelbergCement AG has therefore developed a test procedure, which enables a rapid evaluation and optimisation of shotcrete systems. Called the Beschleuniger-Systemtest (BEST) (accelerator system test), the penetration resistance is determined on pure mortar systems, which considerably accelerates and simplifies the test performance. The BEST is based on the penetrometer test of Kurita Europe APW GmbH, which has been modified by the E&I department. No spraying is necessary for the use of the BEST, and nonetheless the shotcrete performance of the investigated combination of cement and accelerator can be estimated very well.

In the accelerator system test, the penetration force of a penetrometer into a mortar is determined over time after the addition of a defined accelerator. The measured values are mostly recorded over a time of one hour. This is normally sufficient for the evaluation of the initial reactivity of the shotcrete system, which is decisive for overhead spraying. The advance of the penetrometer in the BEST is automatic, so a constant penetration force is ensured. The test rig is shown in Fig. 6.

The BEST is performed in a laboratory climate (20 °C, 65 % relative humidity) on 0.3 litres of mortar. A laboratory assistant can perform 8 to 10 tests per working day and the test has been verified to reliably differentiate various reactive systems.

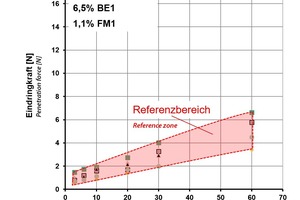

In order to evaluate the reactivity of a system, it is first necessary to know the scatter of the BEST. Fig. 7 shows the scatter for the cement 1 in combination with the accelerator BE1 and the plasticiser FM1.

The scatter is determined for the shotcrete cement using the intended plasticiser and accelerator (BE, FM, type and dose) in the accelerator system test. In parallel, the cement is tested in the same combination under site conditions and the results are documented. In this way tests carried out in the tunnel are correlated with the BEST laboratory tests.

If good results are obtained in the spraying test on site, then the scatter generated using the BEST serves as a reference zone and can be used over the rest of the construction period for the evaluation or monitoring of the reactivity of the shotcrete cement/the accelerated mortar system. The test results of systems that are more reactive than the reference mortar, that is better performing systems, have to be considerably above the associated reference zone in the BEST. Less reactive systems on the other hand lead to test results below the reference zone.

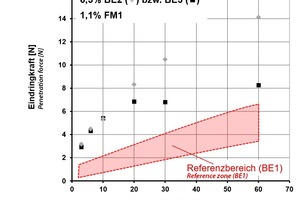

The effect of various accelerator-plasticiser combinations on the reactivity of the system are shown by the test in Fig. 8. The accelerator BE2 shows a significantly better performance than accelerator BE3 with the same dose and also in comparison with the reference zone.

Applications

On large tunnel projects, the concrete is normally supplied from mobile batching plants, which guarantee unrestricted availability of the construction material on site. In particular shotcrete for excavation support has to be available round the clock. The batching plant is normally set up well before the start of tunnelling and can thus be used for initial testing and spraying tests.

In these spraying tests (Fig. 9), the proposed mix is used with the selected shotcrete cement and various accelerators and plasticisers. The concrete is transported to the shotcrete machine in mixer trucks. The concrete should have good workability for at least two hours. As it is sprayed, a defined quantity of an alkali-free accelerator is added at the nozzle. The dose can be adjusted in the course of testing.

During spraying, it is observed whether the rebound is sufficiently small and whether heavy shotcrete layers adhere overhead. Hardening times, early strengths and temperature increases can also be recorded. The results of the shotcrete spraying tests in the tunnel are compared with the laboratory tests with the accelerator system test (BEST).

In Fig. 10 it can be seen that the BE/FM system with the accelerator BE2 showed excellent shotcrete performance under construction site conditions. The results from the spraying tests in the tunnel (Fig. 10) and the laboratory tests with BEST (Fig. 8) are thus in agreement that the accelerator BE2 with the dosage 6.5 % securely reaches the early strength while the shotcrete with accelerator BE1 does indeed lie in the required zone J2 but is less reactive.

Summary

Numerous tunnel projects are being mined and supported with shotcrete in southern Germany. The production and stockholding of a reactive shotcrete cement has been successfully implemented at the Schelklingen plant of the HeidelbergCement AG on the Swabian Alb. Many individual tunnel drives on the Stuttgart–Ulm rail project and further tunnelling projects are using this high-performance cement with success.

The production of the shotcrete cement is carefully monitored at every stage of the process. Additional tests and test series ensure the uniformity and reactivity of the Schelklingen shotcrete cement.

The accelerator system test (BEST) enables the testing of the reactivity of the cement in combination with accelerator additives in the laboratory. This enables any deviations in the performance of the shotcrete cement to by rapidly detected and remedied.

Comparison of BEST results with practical spraying tests in the tunnel normally show very good agreement. The BEST can thus be used in advance of spraying tests to detect which accelerator leads to a particularly reactive shotcrete system in combination with the Schelklingen shotcrete cement CEM I 52,5 N (sb).

Read the Interview wit the authors Dr. Jennifer Scheydt, Dr. Klaus Felsch and Werner Beer