STUVA Research awarded Innovation Prize

Water-permeable Annular Gap Material for Single-Shell Drained Segment LiningsOn 10 October 2018, the Austrian national committee of the International Tunnelling and Underground Space Association (ITA) awarded their innovation prize to the STUVA for the “development of a water-permeable annular gap material for single-shell drained segment linings”. During a ceremony as part of the Austrian Tunnel Day 2018, the trophy was handed to the STUVA and their research partners IMM Maidl & Maidl (Germany), Porr Bau GmbH (Österreich) and MC-Bauchemie Müller GmbH & Co. KG (Germany). The prize committee of the Austrian Tunnel Day regularly awards the prize to particularly creative developments in tunnelling.

Water-permeable Annular Gap Material for Single-Shell Segment Linings

The STUVA and their research partners have succeeded with a development, which will enable the use of the cost advantages of single-pass tunnel lining even under high water pressures.

Until now, segment-lined tunnels were mostly designed to be pressure-tight, with waterproofing provided by gaskets. From a water pressure of about 5 bar, however, a much more laborious and expensive two-layer construction with an additional drainage layer between the inner and outer linings had to be used. With the newly developed pumpable annular gap fill material, this is no longer necessary since the material has sufficiently high permeability to be used as a drainage material.

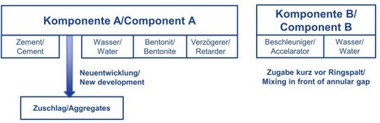

The key idea in the development is the defined foaming of cement suspension with a foam generator to achieve an open-pored and water-permeable structure with sufficient strength to ensure the bedding of the segments. In the test halls of the STUVA, a suspension recipe and the exact dose of the additives were therefore determined and tested in an extensive test series on a specially developed test rig. Strict requirements were posed for the workability, pumpability, stability, water permeability and compressive strength of the material. The scaling behaviour of the material was also investigated in order to ensure its durability.

The innovative annular gap material simultaneously shows several substantial advantages:

Extensive saving of resources through less aggregate and cement

Improved environmental protection through smaller excavated section (less excavated material, less landfill space)

Improved safety since there is no danger of packers shooting out (no blowing of pea gravel)

Shorter construction time through the omission of an additional inner lining (construction in one pass)

Extension of the scope of application of segment-lined tunnels in solid rock through less joint water pressure (simpler waterproofing)

The general suitability of the developed annular gap material has not only been verified in the laboratory but also in site trials. A patent

has meanwhile been applied for.