Planetary Gears for heavy-duty Operation

Tough working conditions prevail in tunnelling. The demands posed on technical equipment are correspondingly high, as e.g. gears, which must reliably cater for movement in various machines. In tunnel boring machines (TBMs) planetary gears must withstand strong vibrations, impacts, high temperatures and pronounced external pressure (Fig. 1). These powerful gears are also applied in building cranes, drilling rigs, cutters, excavators, pumps or tracked vehicles.

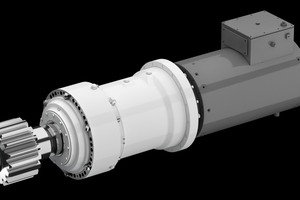

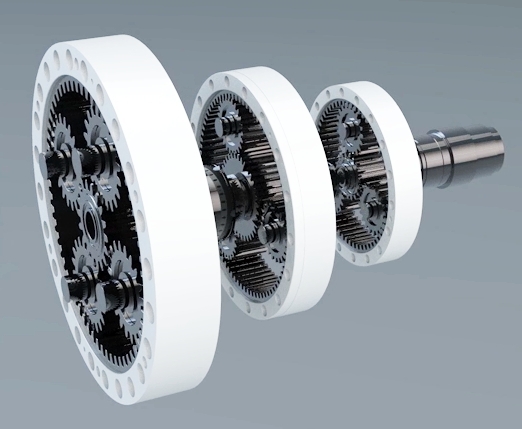

7 Inside view of a planetary gear

7 Inside view of a planetary gear

Credit/Quelle: Zollern

Planetary gears are compact, possess a high power density and high efficiency given low construction space. They are mostly used for heavy-duty operation. Planetary gears are suitable for continuous operation as well as for intermittent and alternating operation or clockwise and anticlockwise rotation.

A gear is charged with adapting a torque and rotational speed to certain requirements. In the case of the main drive of a TBM for example, the driving torque is changed as well as the rotational speed. By and large, a gear possesses a drive, which can be an electric motor, as well as a power output component, which normally forms the final link in the powertrain, transferring the required power and rotary motion. Planetary gears comprise a single to five-stage planetary gear set. In addition, they can be fitted with a spur or a bevel gear stage. In contrast to standard gears with spur gear units this facilitates simultaneous load distribution on several gear wheels. High degrees of efficiency are the outcome of the lower pitch circle speeds. Ground tooth flanks cater for a lower noise emission. The planetary gears have a long service life and perform efficiently, even given harsh conditions under -20 °C to +70 °C. The drive functions via hydraulic motors operating either in fast or slow mode as desired, or via electric motors.

Planetary Gears in Tunnel Boring Machines

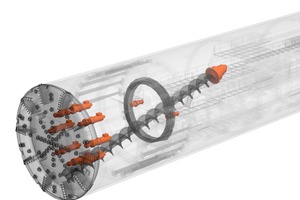

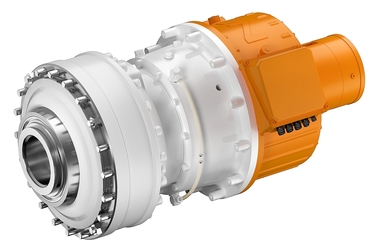

The cutting wheel drive or the cutterhead drive represents the core of a tunnel boring machine. The ball bearing supported ring, a large bearing with internal teeth, possesses a number of sprockets around its circumference, which are driven by hydraulic or electric means via the main gears (Fig. 2). The resultant rotational movement – and similarly the thrust of the hydraulic cylinders – sets the cutting wheel in motion. The Drive Technology Division of the German company Zollern devises planetary gears for smaller shield diameters with an output torque in excess of 3 000 000 Nm. The central drive is water-cooled and transfers the force directly on to the cutterhead centrically. A duct is foreseen in a central position through the toothed parts of the gear up to the cutting wheel so that the machine operator can feed fluids for cooling and bentonite as a lubricant or supporting fluid. Boring is executed in several steps. During the boring process the excavated material, depending on the type of tunnel boring machine, is removed by pumping or transported via a worm drive (Fig. 3) or a belt conveyor. During the excavation the segmental rings are placed in a parallel procedure. Towards this end, the machine operator picks up the segment via remote control with a suction pad, positions it and bolts it in place. For this purpose, the rotational movement for positioning the segments is executed with high precision by means of a hydraulically driven erector drive (Fig. 4).

Global Tunnelling Projects

Zollern supplies the main drives, central drives, worm drives and erector drives, which are specially designed for application in tunnel boring machines on the basis of planetary drives (Fig. 5) for various tunnelling projects. For example, 4.4 m diameter tunnel boring machines, fitted with Zollern drives, excavated the SNCF rail tunnel in Meuden City in the west of Paris. In the CREG (China Railway Engineering Group) factory in Guangzhou in China, two TBMs with a diameter of 11 m were produced for a rainwater project in Dubai. Zollern gear technology also supported the construction of the Koralm Tunnel in Austria and building the Red Line in Israel. The same applies to six TBMs, which were used for producing a modern commuter transportation system in Tel Aviv. Apart from CREG, the CRCHI China Railway Construction Heavy Industry, CCCCTH Tianha Mechanical Equipment Manufacturing as well as European manufacturers, for instance, CSM Bessac in France, are numbered among Zollern’s customers. The company operates on a global basis and has a dense service network available particularly in China. This also includes its own plant in China, where gears and winches are manufactured. Zollern has also invested in a new international service centre at its German headquarters in Herbertingen (Fig. 6). From here, customers are provided with spare parts as well as maintenance and repair jobs carried out, and service teams set off on their assignments all over the world. The essential spare parts are readily available as they are produced according to modular design. This signifies that there is a propensity of gear parts, which are structurally and systematically identical, so that there is no need for too many parts, thus optimising supply.

Fields of Application in Tunnelling in General

Planetary gears enable high torques to be transferred. In operation the emit a low noise level and afford the opportunity to adapt hydraulic and electric motors. The integrated water-cooling system is also advantageous for applications in tunnelling in general. For example, Zollern also uses planetary gears in special portal cranes for assembling tunnel boring machines on-site. Further examples of the application of planetary gears are drilling rigs for special foundation engineering for stabilising the earth, cable excavators for dynamic soil compaction and cold milling machines for removing asphalt, concrete and gravel layers as well as milling drives for rectangular tunnel boring machines. In addition, planetary gears are applied in mobile concrete pumps for handling building material, in mobile cranes for positioning structural elements and machinery as well as in drive systems for tracked vehicles.

Switch Gearbox Development Project

Zollern runs development projects for the continuous advance of the entire drive sector, also in conjunction with customers. One example is the challenge to adapt tunnel boring machines to geological conditions without particular effort. Towards this end, a universally applicable switch gearbox with hydraulically controlled switch unit was developed, which can be operated via remote control from the operator’s cabin. In accordance with customer specifications the transmission ratios for hard rock and soft, unstable geological conditions are chosen. Combined with a frequency-controlled motor or a continuous hydraulic motor the speed-torque-characteristic diagram is doubled given the same output.

In order to achieve a simultaneous switching operation for all the gears arranged around the ball bearing supported ring, sensors secure the correct switching position of every individual gear. The switching mechanism is continuous and corresponds to the principle of a motor vehicle automatic transmission. A misalignment of the individual gear wheels during the switching process is precluded, as transmission is carried out via a non-positive or friction-type connection. Preset temperature sensors monitor the oil temperature and prevent the gearbox from overheating. Heat is removed via an integrated cooling water circuit. Should there be a need for the cutting wheel/cutterhead to be serviced, the gearbox’s integrated holding brake function comes into play in order to prevent the cutting wheel from rotating.

Compared with the standard gearbox without gear changing, the shift gearbox is no larger in spite of the additional switch unit and thus offers substantial added value given unaltered space conditions.

Zollern carries out research activities, including some in collaboration with universities, and integrates them in product-specific projects. Future marketing trends are recognised at an early stage and taken into consideration through cooperation in working groups, for example the Research Association for Drive Technology (FVA).

Zollern Drive Technology

Zollern Drive Technology is a business segment of the tradition-steeped Zollern company, made up of the five divisions Drive Technology, Bearing Technology, Foundry Technology, Steel Profiles and Engineering Elements. In all, Zollern employs a workforce of around 3000 and is represented in all the world’s industrial regions with 14 plants and seven subsidiaries. With its company history stretching back 300 years, Zollern is numbered among the pioneers of the metal industry. The construction machinery industry represents one of the company’s core activities.

Zollern-Antriebstechnik, with its headquarters in Herbertingen and a labour force of some 600, manufactures gears, winches and direct drives for the construction machinery industry, underground mining, wind energy as well as shipping and port facilities. The drive technology specialist also provides after sales service such as installation support, commissioning service, spare parts service, retrofitting, maintenance and status monitoring of operational gears and winches.