Drives for Tunnel Boring Machines

With the increasing length of tunnel projects, it is increasingly necessary for tunnel boring machines (TBM) to be capable of working in different geologies along the intended alignment. Modern hybrid machines can be adapted to suit changing ground conditions, ranging from self-supporting rock to muddy, watery soils. In addition to appropriately adapted support measures, above all the boring parameters have to be selected considering the ground conditions and the presence of adjacent buildings and structures.

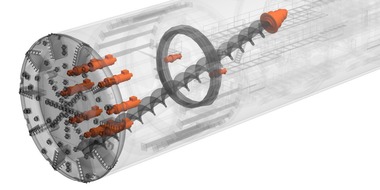

The significant adaptable features of a cutterhead are the cutting tools and the cutterhead geometry with muck conveyance. The various tools chosen to cope with the ground encountered are operated with adapted cutting speed and thrust force in order to optimise the energy consumption and advance rate of the machine. For the rotary drive of a TBM cutterhead, this results in the task of providing the variable power required for various combinations of rotation speed and torque. The tendency for machines working in hard rock environment is to require maximum machine power at higher rotation speeds, whereas in the EPB environment, rather lower power and rotation speed are needed.

TBM cutterheads are normally driven through a ring gear. Several drive units at the perimeter, each normally with a water-cooled asynchronous motor and a water-cooled multi-stage planet gear, drive the ring gear through pinions. The motors are speed regulated.

Drive Through Shift Gearbox

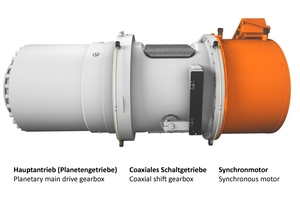

Considering the required range of operating states, a standard drive system cannot always be operated at a favourable operating point. The energy consumption is then unreasonably high or the intended combination of rotation speed and torque cannot be driven permanently. In order to cope with these changeable working conditions, drives which can operate over a wider working range are necessary. For this purpose, the drive technology specialist Zollern from Germany has developed a shift gearbox, which can also be retrofitted to existing TBMs. The two-stage shift gearbox with a neutral position is mounted coaxially between motor and gearbox and has connection geometry corresponding to the motor on the gearbox side, and on the motor side it has the same geometry as the main gear. The diameter is the same as the main drive. Another precondition for the retrofitting capability is the separate cooler. The shift gearbox enables direct drive from the motor or reduction of motor revolution speed by available gear ratios of 1.3 to 2.3, with a corresponding increase of the available drive torque. This considerably widens the range of application of the drive and thus of the entire tunnel boring machine.

The gear is changed hydraulically when no load is applied. The three gear positions, first second and neutral, are monitored by sensors. The two gear ratios make it possible to provide drive power in two ranges of revolution speed. The neutral position enables the uncoupling of individual motors and thus operation of the machine under partial load at a revolution speed that may be more favourable for the individual motors. By separating the motors not used in current operation from the machine‘s drive train, most of the rotary inertia of the drive units not required is removed from the drive train

The two gear ratios and the capability of uncoupling the motors mean that the motors can be operated at a more favourable working point over a wider working range of the machine. The flexibility of the TBM is improved by the Zollern drive system.