45% CO2 Reduction Achieved in Cement Production for Stuttgart 21 Tunnel Project

The CEM III/A 52.5 N-SR cement developed by Schwenk sets new standards in tunnel construction in terms of environmental compatibility. Thanks to a lower proportion of clinker, around 160 000 t of CO2 and thus over 45% of cement-related CO2 emissions could be avoided in the major Stuttgart 21 project.

1 | Finished tunnel inner lining with CEM III/A 52.5 N-SR

1 | Finished tunnel inner lining with CEM III/A 52.5 N-SR

Credit/Quelle: ARGE ATCOST 21

Tunnel construction continues to play an important role in the implementation of infrastructure projects. Against the background of the current climate debate, however, tunnel projects are also increasingly criticised in terms of CO2 emissions [1]. However, new developments in cement and concrete can significantly reduce production-related CO2 emissions. While in the past CEM I cements were usually used in tunnel construction, clinker-reduced and thus more climate-friendly cements are now to be applied increasingly [2]. In this article, the blastfurnace cement CEM III/A 52.5 N-SR from the Schwenk supplier plant in Karlstadt used for the Stuttgart 21 project is presented (Fig. 1). Compared to CEM I cements, this cement reduces the production-related CO2 emissions by almost 50% for the same input quantity. At the same time, it enables the production of high-performance and highly durable concretes that achieve a service life of 100 years and more, even under the special groundwater and soil conditions in the Stuttgart basin.

The Project

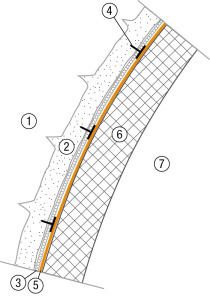

2 | Overview of Stuttgart 21 and the new Wendlingen–Ulm line

2 | Overview of Stuttgart 21 and the new Wendlingen–Ulm line

Credit/Quelle: DB

German Railways (Deutsche Bahn) is currently building the Stuttgart–Ulm project, which involves a total of six new stations, 120 km of tunnels and 81 bridges. The project consists of two sections: on the one hand, Stuttgart 21, the complete reorganisation of the Stuttgart railway junction, which has been under construction since 2010, including the connection of Stuttgart Airport to the high-speed railway network and a section of free track to Wendlingen, and on the other hand, the high-speed line Wendlingen–Ulm, which has been under construction since 2012. The high-speed line goes into operation in December 2022, the commissioning of Stuttgart 21 is planned for the end of 2025 (Fig. 2).

Fundamentals and Requirements

There are different types of tunnelling. Driving with a tunnel boring machine can only be used under certain conditions. An example of this is the Boßler Tunnel, on the new line at the Albaufstieg [3]. In conventional tunnelling, on the other hand, the rock is loosened by means of blasting or excavators and immediately secured with sprayed concrete [4]. In the past, dry shotcrete was sometimes used for securing. However, due to dust emissions, the lower hourly output and the high rebound in tunnel construction, this method has almost completely disappeared. Especially for larger tunnel construction projects, wet shotcrete has been established. With this method, the concrete is mixed in a site mixing plant or a nearby ready-mix concrete plant and transported by truck mixer to the point of use. The concrete is conveyed to the spraying mobile or to the spraying nozzle by means of piston pumps. Before exiting the spray nozzle, the concrete stream is dispersed by compressed air and mixed with a liquid accelerator. Afterwards, the concrete must adhere to the rock (also overhead), set and harden quickly. The requirements regarding strength development in the first minutes and hours go far beyond what is demanded in normal civil engineering or precast construction. This is the only way to ensure the safety of the construction workers during tunnel excavation and to achieve an appropriate performance. The classification of sprayed concrete is carried out according to its strength development in accordance with the “Austrian Sprayed Concrete Guideline” [5] in the so-called J-curves.

For environmental reasons, only “alkali-free” accelerators based on aluminium salts are used today. The costs for these accelerators account for a considerable share of the total concrete costs. Consequently, attempts are made to keep the consumption of these admixtures as low as possible and thus ensure the economic viability of the construction project. The influence of the cement and the concrete composition on the accelerator consumption is immense.

The tunnel inner lining fulfils the essential load-bearing function to permanently secure the tunnel with lifetimes of 100 years and more. A formwork carriage is used for the construction of this inner lining. The space between the formwork facing on the formwork carriage and the sealing on the shotcrete lining is filled with fresh concrete using a concrete pump. Usually, the sections for the tunnel inner lining are produced in a 24-hour cycle. For this purpose, the concrete must develop a strength of at least 3 N/mm² within 8 hours under the climatic conditions of the tunnel, with ambient temperatures of approx. 10°C, to allow the formwork carriage to be lowered in shift production.

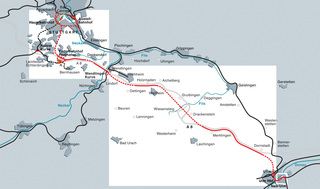

Table 1 | Requirements for the sprayed concrete and inner lining concrete in the Stuttgart 21 project sub-area Stuttgart valley basin

Table 1 | Requirements for the sprayed concrete and inner lining concrete in the Stuttgart 21 project sub-area Stuttgart valley basin

Additional demands on the concretes used in the area of the Stuttgart basin result from the conditions that attack the concrete. In particular, the sulphate content in the gypsum keuper in combination with the lime-dissolving carbonic acid of the existing groundwater lead to a classification in the exposure class XA2 (moderate chemical attack) and XA3 (strong chemical attack) according to DIN EN 206-1/DIN 1045-2 [6]. The requirements for the concretes to be used are defined in several expert reports by Schiessl-Gehlen-Sodeikat engineers [7]. According to the expert opinion, these requirements apply to both the inner lining concrete and the sprayed concrete used. The various requirements that arise for the concretes in the Stuttgart basin are summarised in Table 1.

Development of the Sprayed Concrete Cement

Due to the required durability, the use of a pure Portland cement (CEM I) for the sprayed concrete and the inner lining could be excluded. According to the experts [7], cements with a high content of granulated blastfurnace slag should be used in combination with fly ash as an additive. Furthermore, a reduced w/c ratio of ≤ 0.45 or ≤ 0.40, depending on the degree of attack, is recommended for the concretes. In this way, the durability of the concretes could be ensured for 100 years and more. Especially blastfurnace cements of the type CEM III/B with a blastfurnace slag content of 66 to 80 wt.% would be the best variant from this perspective. Normatively, cements with a blastfurnace slag content of ≥ 66 wt.% are generally classified as "SR" (sulphate resistant).

However, a high blastfurnace slag content has a disadvantageous effect on the early strength development of corresponding concretes. Especially blastfurnace cements rich in blastfurnace slag harden very slowly. This property prevents their use as sprayed concrete or as concrete for an inner tunnel lining. As explained above, sprayed concretes must ensure very rapid setting and concretes for tunnel linings must ensure rapid strength development. Neither sprayed concretes nor concretes for the inner tunnel lining can be realised with a slow-setting CEM III/B cement.

To be able to fulfil all the above-mentioned requirements as far as possible, a moderate granulated blastfurnace slag content of the cement is recommended. A high sulphate resistance can be achieved with a blastfurnace slag content of at least 50 wt.% [8]. However, for a high early strength or even a high resistance to freezing or de-icing salt attack of the manufactured concrete, the blastfurnace slag content should be kept to a minimum if possible [9]. For further cement development, the blastfurnace slag content was fixed at 50 wt.%.

A high performance of blastfurnace cement and the concretes made from it requires separate grinding of the blastfurnace slag and clinker components [10]. For rapid strength development, not only the clinker but also the blastfurnace slag must be available with a high grinding fineness. The gradation of the particle size distribution of both components ensures a low water demand of the cement and thus an easy workability of the concrete.

In addition to the correct composition of the main cement constituents granulated blastfurnace slag and clinker, the composition of the setting regulator calcium sulphate must also be optimised for the specific applications. In addition to the total calcium sulphate content, it is primarily the anhydrite/gypsum ratio that determines the performance of the cement in the respective application. For sprayed concrete in particular, slow consumption of the calcium sulphate has a beneficial effect on strength development. Small amounts of limestone powder are often added to the cements as a secondary constituent. However, this increases the risk of damaging thaumasite formation under the climatic conditions of the tunnel [11]. Consequently, the addition of carbonate-containing secondary constituents was dispensed with.

Sulphate Resistance

The blastfurnace cement adjusted in this way leads to a very dense concrete structure. A high sulphate resistance of the cement was expected due to the composition, but had to be proven separately within the scope of an application approval. In this test, a direct comparison is made with a reference cement based on the Portland cement CEM I SR 3. In this comparison, the tested specimens with blastfurnace cement were characterised by very low elongations and remained significantly below the limit value relevant for this test. After this approval test, the cement could be registered and marketed with the designation CEM III/A 52.5 N-SR [12].

Suitability Test in the Spraying Stand

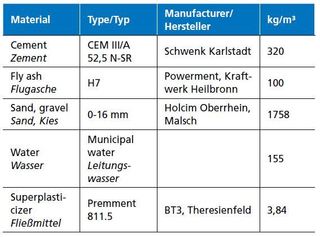

The suitability of the cement in sprayed concrete was proven by extensive preliminary tests with commercially available accelerators. In addition to the setting behaviour, the early strength development is also evaluated. The suitability of the cement was verified under practical construction conditions in the Schwenk spraying stand. This was preceded by concrete-technological formulation adjustments. The following basic composition proved to be particularly efficient and robust:

380 kg/m³ Cement

40 kg/m³ Fly ash

w/ceq ratio 0.45–0.50

PCE superplasticizer

Largest grain size 8 mm gravel

Spreading dimension F5 for approx. 120 minutes

3 | Production of the sprayed concrete boxes on the test stand

3 | Production of the sprayed concrete boxes on the test stand

Credit/Quelle: Schwenk

A spraying stand consists of several tunnel segment arches next to each other. In this way, spraying can also be simulated overhead. To determine the strength development of the accelerated sprayed concrete, wooden boxes specially made for the measurements are filled with sprayed concrete (Fig. 3). The strength development can then be measured for up to 24 h using a penetration needle (Fig. 4) or a pull-out test (Fig. 5). While the penetration needle covers the test range from 0.2 to 1 N/mm², the pull-out method is used for the test range 2.5 to 15 N/mm². Here, the pull-out force is measured on a nail previously driven into the hardened sprayed concrete by means of a bolt gun and the compressive strength is determined from this via correlation values.

4 | Measuring with penetration needle on sprayed concrete boxes

4 | Measuring with penetration needle on sprayed concrete boxes

Credit/Quelle: Schwenk

5 | Bolt gun for the pull-out test

5 | Bolt gun for the pull-out test

Credit/Quelle: Schwenk

The strength curve after 24 h (test range from approx. 15 N/mm²) can only be determined by direct measurement of the compressive strength. For this purpose, drill cores are taken from the spray boxes, ground plane-parallel and tested destructively.

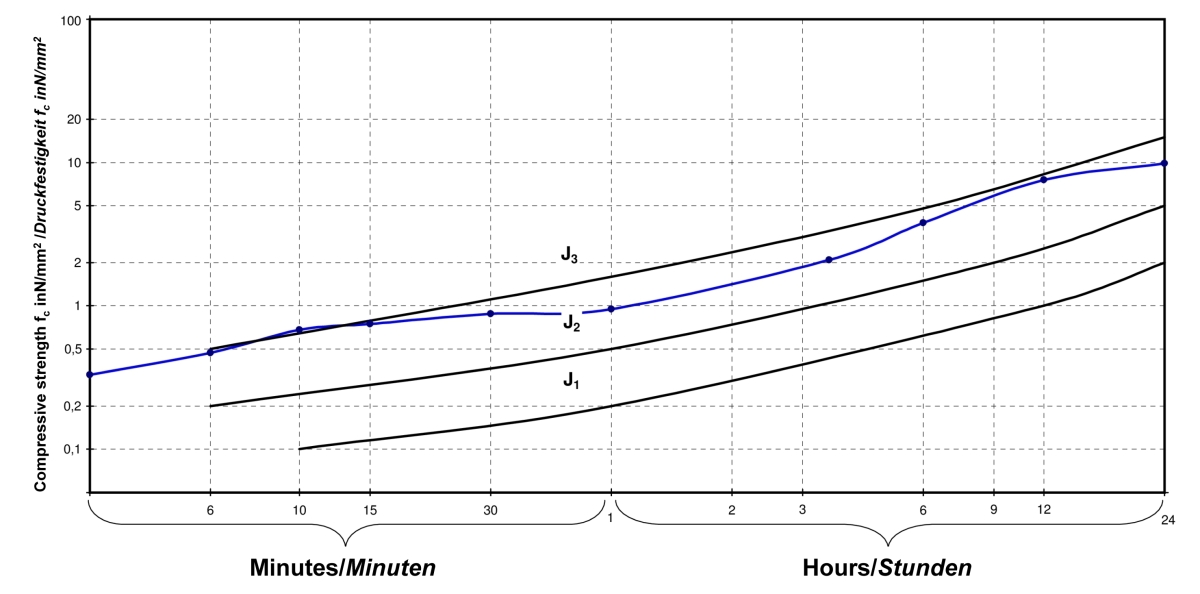

The tests have shown that the CEM III/A 52.5 N-SR is comparable with the usual sprayed concrete cements CEM I 52.5 R regarding the fresh and hardened concrete properties. In addition, concrete tests at temperatures below 10°C proved the suitability of the cement as an inner lining concrete. Figure 6 shows an example of the strength development of the sprayed concrete with an accelerator addition of 6.5 wt.% in relation to the cement content. These are good values with regard to the framework conditions.

6 | Strength development of a sprayed concrete with CEM III/A 52.5 N-SR and 6.5 wt.% accelerator, related to the cement content and 19°C fresh concrete temperature

6 | Strength development of a sprayed concrete with CEM III/A 52.5 N-SR and 6.5 wt.% accelerator, related to the cement content and 19°C fresh concrete temperature

Credit/Quelle: Zertplus

Examination of Durability

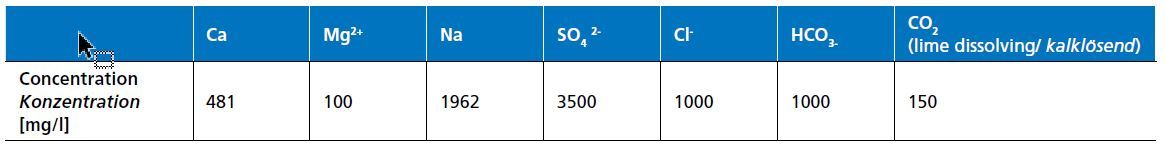

Parallel to the above-mentioned approval tests, further durability tests were carried out at the Centre for Building Materials and Material Testing at the Technical University of Munich (cbm). The analyses of various Stuttgart groundwaters could be taken from the tender documents and expert reports. For long-term tests, the most unfavourable groundwater composition was selected and simulated in the laboratory. Table 2 shows the composition of the test solution. Subsequently, test specimens with different binder combinations were stored in this solution and exposed to the chemical influence for one year. The special feature of this test is the parallel influence of sulphate and lime-dissolving carbonic acid. To maintain the carbon dioxide concentration, carbon dioxide gas was pumped into the solution during the entire storage period. As in the “SVA method”, cement stone flat prisms with measuring pins were used as test specimens for the sulphate resistance. In addition to the elongation of the test specimens, they were examined for the formation of the harmful mineral thaumasite after the end of storage. These tests showed that the CEM III/A 52.5 N-SR has the highest resistance to the attacking medium compared to other SR cements [13].

Table 2 | Composition of the least favourable test solution

Table 2 | Composition of the least favourable test solution

Since the market launch of CEM III/A 52.5 N-SR from Schwenk's Karlstadt supply plant, the quality of the cement has been monitored twice a week in the cement laboratory as part of the plant's own production control. In accordance with the cement standard DIN EN 197-1 [14], the water demand, binding times, and strengths are tested in addition to the chemical composition and particle size distribution. However, these tests have only limited significance regarding the suitability of the cement as sprayed concrete. To ensure the performance of the sprayed concrete over the entire construction period, a special quality test was introduced. In this process, a cement paste is produced with a high-performance mixer and mixed with a standard accelerator. Immediately afterwards, the start of setting is determined. Special test specimens, in which the cement paste is mixed together with the accelerator directly in the test specimen formwork, allow the determination of the early strength development for up to 24 hours.

Practical Application for Stuttgart 21

The contract for the tunnel section from Stuttgart-Untertürkheim to Stuttgart Central Station was awarded to the ATCOST 21 consortium, consisting of the companies Porr, Hinteregger, Östu-Stettin, and Swietelsky. For the delivery of the concrete, the consortium chose Semper Beton, a subsidiary of Schwenk Zement GmbH & Co. KG. By the end of 2021, 1 450 000 m³ of concrete with CEM III/A 52.5 N-SR from the Schwenk cement plant in Karlstadt had been been produced in the Stuttgart basin.

As an application example, the following section presents the lot 1B, tunnel to Ober- and Untertürkheim. The tunnel consists of two approximately 6 km long tubes, most of which are excavated conventionally and supplied via an intermediate point of attack. The intermediate access is designed as a 37 m deep, vertical shaft with a diameter of 22 m and a 110 m long access tunnel to the actual tunnel bores. The concrete is produced in a mobile plant directly at the shaft (Fig. 7). Downpipes are used to convey the concrete into the shaft (Fig. 8). This procedure requires a robust concrete that is stable against segregation.

7 | Aerial view of the Ulmer Straße construction site with mixing plant

7 | Aerial view of the Ulmer Straße construction site with mixing plant

Credit/Quelle: Arnim Kilgus

8 | Concrete discharge at the access shaft Ulmer Straße into the truck mixer

8 | Concrete discharge at the access shaft Ulmer Straße into the truck mixer

Credit/Quelle: Arnim Kilgus

Sprayed Concrete

9 | Start of conventional excavation at the intermediate access point Ulmer Straße

9 | Start of conventional excavation at the intermediate access point Ulmer Straße

Credit/Quelle: Arnim Kilgus

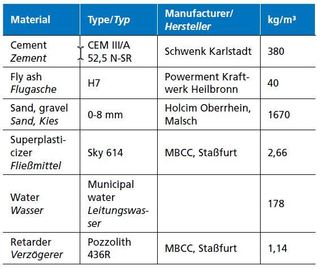

The sprayed concrete (Fig. 9) is designed in strength class C35/45 and exposure classes XC4, XA3 with the largest aggregate grain size of 8 mm in consistency class F5 with a processing time of 3 hours (see Table 3). The sprayed concrete has been produced since 2013 and has since proven to be extremely consistent, robust and reliable. The setting accelerator used was determined in extensive preliminary tests. Consumption was always within a range of the dosing quantities determined in the initial test. The system proved to be very economical, also with regard to the water ingress in the tunnels. Due to the low-clinker formulation, minimum fresh concrete temperatures of ≥ 22°C were necessary. This value was easily achieved with the existing plant technology in the mobile mixing plant.

Table 3 | Composition of sprayed concrete C35/45

Table 3 | Composition of sprayed concrete C35/45

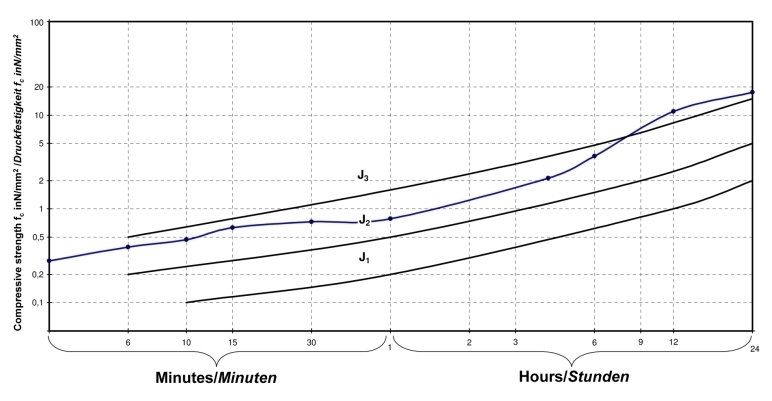

Due to the low Portland cement clinker content, the formulation also has a very low scaling potential and thus reduces the maintenance effort of the drainage system. The typical early strength development of the sprayed concrete system used is shown in Figure 10.

10 | Strength development of sprayed concrete with

10 | Strength development of sprayed concrete with

7 wt.% accelerator addition Alucom Gecedral F100A on site (fresh concrete temperature 25°C)

Credit/Quelle: Zertplus

Tunnel Inner Lining

11 | Production of the tunnel inner lining with formwork carriage

11 | Production of the tunnel inner lining with formwork carriage

Credit/Quelle: ARGE ATCOST 21

Due to diverging requirements, a different cement is usually used for the tunnel inner lining (Fig. 11) than for the sprayed concrete. However, due to the required durability and the design life of > 100 years, the CEM III/A 52.5 N-SR was also used for the tunnel inner lining in the project. In addition to the exposure classes XA2 and XA3 and the strength class C50/60, the maximum component temperature of 55°C had to be complied with for lining thicknesses of up to 1.2 m. At the same time, the stripping strength of > 3 N/mm² had to be reached after 8 hours in order to be able to realise a daily cycle. The massive reinforcement content of up to 350 kg/m³ requires good workability of the concrete. The partly long conveying distances required good pumpability. All these properties could be fulfilled with a concrete mix using CEM III/A 52.5 N-SR (Table 4). It was also logistically advantageous that only one cement had to be used.

Table 4 | Composition of the inner lining concrete

Table 4 | Composition of the inner lining concrete

Environmental Considerations

Against the backdrop of climate change and the associated requirements to reduce CO2 emissions, ecological considerations are becoming increasingly important in the construction of major projects. Schwenk is making great efforts here to achieve the targeted rapid climate neutrality of cement as a building material. The reduction of the clinker content and the use of high proportions of other main constituents make a significant contribution to this.

However, there are limits to this approach. On the one hand, the availability of the main constituents such as granulated blast furnace slag, fly ash or trass is limited. On the other hand, the reduction of the clinker content can have a negative impact on the durability of the concretes produced with it. Blastfurnace slag has a convincing performance with regard to the durability of the concretes, especially under the influence of chemical processes. The results of the expert investigations [13] have confirmed this.

In principle, the evaluation of the sustainability of building materials must be carried out via uniform and standardised systems in order to objectively assess and compare building materials and construction projects.

The Concrete Information Centre (IZB) published environmental product declarations (EPDs) for average cements and concretes several years ago. These can be used in the certification and sustainability assessment of structures and buildings. Among the environmental impacts of the building materials stated in the EPDs, the Global Warming Potential (GWP) quantifies the CO2 emissions per production unit (e.g. t, m³) as an essential key figure.

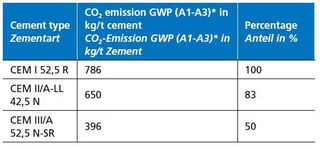

Since many customers no longer want to calculate with average data, but rather demand plant-specific data, Schwenk uses the established software of the GCCA (Global Cement and Concrete Association) to calculate environmental product declarations. Table 5 shows examples of different cements and the corresponding specific CO2 emissions (GWP).

Table 5 | CO2 emissions (global warming potential/GWP) of various cements and savings potential in %

Table 5 | CO2 emissions (global warming potential/GWP) of various cements and savings potential in %

In the project described above, 262 000 t of sprayed concrete cement have been processed so far using CEM III/A 52.5 N-SR from the Karlstadt supply plant. Assuming that a concrete with CEM I 52.5 R would have a comparable composition, this means a saving of more than 100 000 t CO2 emissions through the use of CEM III/A 52.5 N-SR. For the comparison of the inner lining concrete, the CEM II/A-LL 42.5 N is used as a basis. Even there, the use of the CEM III/A 52.5 N-SR cement results in a saving of 58 000 t of CO2 emissions, with a cement consumption of 228 000 t.

It can thus be stated that in the project described above, the cement selection and use of CEM III/A 52.5 N-SR from the Schwenk supplier plant in Karlstadt alone has so far resulted in a saving of approx. 160 000 t of CO2 emissions. This corresponds to a reduction of over 45% of cement-related emissions. A huge figure, which shows that sustainable construction is possible even for a demanding building task.

Conclusion

The CEM III/A 52.5 N-SR cement developed by Schwenk enables the economical production of sprayed concrete and tunnel inner lining concretes with high durability. Even under the special conditions of the Stuttgart basin, tunnel constructions with a design life of over 100 years are possible. The low clinker content of the cement also reduces the production-related CO2 emissions. Compared to previous tunnel projects, around 160 000 t of CO2 and thus over 45% of the cement-related CO2 emissions can be avoided.