Tunnelling in Malaysia

Tunnelling and underground space solutions in Malaysia have undergone a very successful development in the last two decades, starting with the elaborate design of the well-known SMART project in Kuala Lumpur 15 years ago. Recently the innovative Variable Density tunnel boring machine for the MRT Klang Valley project won international awards and respect from tunnelling professionals all over the world. Malaysia has come of age, as it seems, in technical innovation for tunnelling solutions, and consequentially the Tunnelling & Underground Space Technical Division of the Institution of Engineers Malaysia (IEM) now has submitted its bid for Kuala Lumpur to host the ITA-AITES World Tunnel Congress (WTC) 2020

In Malaysia, tunnelling took on an important change in 2003 when there was an acute need to address major flooding issues in the city of Kuala Lumpur. With the city densely built up to the brims, the flood mitigation infrastructrure had to be taken underground via tunnelling, and the geology in which the tunnel snakes through the city is made up of extreme karst. Building on the experience gained and technological improvements in the industry, the SMART (Stormwater Management and Road Tunnel) broke new ground not only in the country but worldwide by combining the functions of stormwater drainage and motorway tunnel. With 9.7 km length the SMART is one of the longest stormwater tunnels in South East Asia. The large 13.2 m diameter tunnel was constructed using a slurry shield TBM. Its construction posed a number of challenges, primarily related to the karstic limestone formation through which the tunnel had to be driven. These challenges were met and overcome by good engineering in design and construction.

Malaysia’s unprecedented Tunnelling Challenges

The slurry TBM can normally deal with unexpected cavities if these cavities are filled by washed in soil, which prevents large quantities of slurry loss to the karst system.

On the SMART project, while the low density bentonite slurry based face support did work while traversing minor fissures and filled cavities encountered in the karst, there were incidences of surprise sinkholes and blowouts, and there had to be a much more

sophisticated slurry machine to deal with this problem. When the TBM hits an only partly filled karst cavity, large fissures in the rock or a very loose overburden soil pocket, there is a tendency for the low density (1.1 t/m3) and therefore low viscosity bentonite slurry to escape into the karst channels or to the surface through the connecting fissures and there would occur a blowout. The resulting instant loss of face support pressure would then cause sinkhole formation.

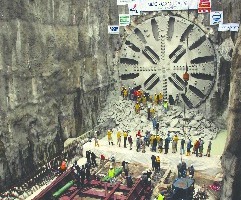

The necessity to continue dealing with the difficult ground conditions eventually resulted in the design of the Variable Density (VD) TBM by Herrenknecht AG from Germany and MMC-Gamuda, for the 9.5 km stretch of a twin-tunnel with seven underground stations for the 51 km long Klang Valley MRT Line 1 (Sungai Buloh-Kajang Line).

After learning the lessons from the tunnelling construction of the SMART project, a total of eight TBMs – two CRTE (China Railway Tunnelling Equipment Co Ltd) EPB machines, one Herrenknecht EPB machine and five Herrenknecht VD slurry machines – have been excavating the twin-tube running tunnels since 2012 successfully.

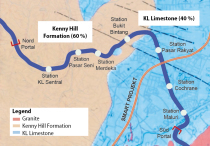

The alignment under one of the busiest and most built-up urban areas in Kuala Lumpur is divided into 5.45 km in the Kenny Hill Formation with sedimentary deposits (three EPB machines) and 3.32 km through the extreme karstic conditions of the Kuala Lumpur Limestone (five VD slurry machines). The VD machines are specially modified slurry shields built to deal with the highly weathered Kuala Lumpur Limestone geology, which is highly karstic.

The VD TBM achieves control by adapting to varying ground conditions better than a typical EPB or slurry TBM. It is built with the capability to vary the support medium density coupled with multiple operation modes offering options for face support control and muck removal flexibility. Also the VD TBMs can be converted to the EPB mode: a VD TBM was converted into a EPB machine to replace one of the planned EPB machines, because excavation headed through a mixed face and the Kenny Hill Formation. The conversion achieved within the tunnel heading was very cost-effective and was done in less than a week. Compared with the SMART project in the same karstic limestone, a 95 % reduction of sinkhole incidents was attained by using the Variable Density technology.

Operation of the first section of the MRT Line 1 started at the end of 2016, and the second section will be operational in July 2017. MRT Line 2 (Sungai Buloh–Serdang

Putrajaya Line) with a planned length of 52.2 km is currently in the detailed design stage for the elevated sections. Construction work of Line 2 started in early 2017, and the 13.5 km long underground section was awarded to MMC-Gamuda.

Once completed, the new triple line MRT system with a length of 156 km altogether will cover a radius of 20 km around the city centre. It will consist of two main lines and one orbital line.

Tunnel Boring Machines are the Way to go

In Malaysia, there are two commonly used types of TBM in recent years, depending on the means used to support the excavated face, the slurry shield machine and the earth pressure balance (EPB) machine. The slurry shield machine supports the unstable ground at the front of the machine with a liquid mixture, e.g. of bentonite and water. On the other hand, the EPB machine, which is most useful in soft soils, uses the excavated ground as a part of the face support.

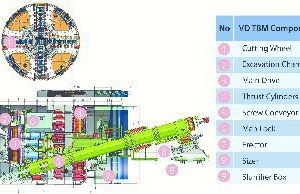

Variable Density TBM Design

The Variable Density TBM is an incremental modification of the machine and with that a major innovation. It merges the slurry and EPB technologies. The machine can operate either in pure slurry mode or in EPB mode with short conversion time of less than a week. In slurry mode the density can be increased up to 1.6 t/m3 by adding solids to the mix.

The VD TBM applies innovative technology by combining the advantages of both methods in one machine. Without mechanical modifications the machine can switch between four different tunnelling modes directly inside the tunnel. This means that geological and hydro-geological changes along the alignment can be managed flexibly. The excavated material is removed from the pressurised excavation chamber through a screw conveyor both in the earth pressure and in the slurry mode. Depending on the mode used, the support pressure is controlled via the screw conveyor speed and advance rate or using slurry that is automatically controlled by an air cushion. The submerged wall opening is replaced by communicating pipes. In EPB mode the screw conveyor drops the excavated material onto a belt conveyor. An additional slurryfier box at the end of the screw conveyor makes it possible to drive the TBM with a hydraulic slurry circuit in slurry mode. In the latter case, either a normal bentonite suspension or a high-density suspension can be used. By introducing a small amount of slurry into the excavation chamber, the consistency of the material maintains high viscosity and high density levels, reducing the risk of slurry loss into karst crevices or due to blow outs to the surface. In slurry mode, the higher density material is extracted from the chamber by the screw conveyor and discharged into the slurryfier box where it is mixed into the circulation slurry for pumping out to the treatment plant on the surface. This makes the range of application of the VD-TBM even larger and makes the machine the all-rounder for loose soils of all kinds.

With the VD TBM technology tunnelling has been reinvented in Malaysia with all conservative rules broken and achieving what was considered the impossible. Malaysian tunnelling experts have come of age and are highly regarded for having honed the right skills and gaining the expertise to take tunnelling to a next level in innovation technology.

MMC-Gamuda

Home-grown construction outfit MMC-Gamuda credits itself as Malaysia’s foremost tunneller and is continuing to build on its strength by expanding on human capital needs in the niche tunnel engineering.