Water Tunnel in Kuala Lumpur

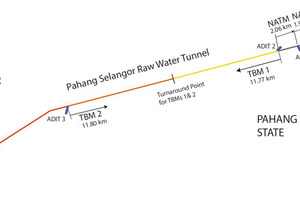

The 44.6 km long Pahang Selangor Water Tunnel is utilizing 3 Main Beam TBMs from Robbins to excavate under complex, high cover conditions in the mountains outside of Kuala Lumpur/Malaysia. The tunnel will bolster dwindling supplies in the capital city by transferring water from other areas.

At 44.6 km long below mountainous hard rock, hot springs, and fault zones, Malaysia’s Pahang Selangor Raw Water Tunnel is no easy excavation. A tireless workforce, hailing from Indonesia, Thailand, Japan, the U.K., and Malaysia are assigned to each of 3 TBM sites as well as several NATM sites, where they work in shifts. Supplies are trucked in and components such as invert segments are cast daily on the TBM sites out of necessity due to the remote project locations outside of Kuala Lumpur. “We’ve got over 33 km of TBM excavation in really different rock conditions. We are going from 230 MPa rock strength in one tunnel down to 50 MPa and blocky ground in another tunnel. These machines have been able to handle everything we’ve thrown at them, while maintaining good advance rates,” said Andy Birch, Robbins site manager at the Adit 4 site. As of Spring 2012 three 5.23 m diameter TBMs were averaging 500 m per month with maximum rates as high as 721 m. Their innovative means to achieve these rates ranges from custom muck removal to novel ground support to high-tech wireless data analysis.

One of the Longest Tunnels in Southeast Asia

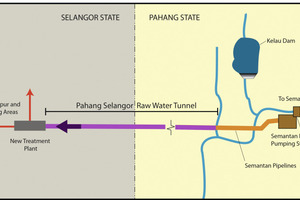

Kuala Lumpur, a city of 7.2 million people, is a former tin mining town ideally located in the bowl-shaped Klang Valley surrounded by mountains. Now the most populous city in Malaysia, the water supply sourced from local rivers is projected to run short in the near future. To address forecasted needs, the Malaysian Ministry of Energy, Green Technology, and Water (KeTTHA) has commissioned the Pahang-Selangor Raw Water Tunnel – one of the longest tunnels in Southeast Asia. The conduit will transfer water from the Semantan River in Pahang State to the Selangor/Kuala Lumpur region, travelling as deep as 1,200 m beneath the Titiwangsa mountain range.

Up to 27.6 m3 of raw water per second is scheduled to begin flowing through the completed tunnel by May 2014. An 858 m long inlet conduit structure and pumping station, located in the Pahang River Basin, will draw water from the river to the tunnel, while outlet structures in Selangor will transfer the water to the site of a new treatment plant. In order to excavate swiftly in difficult high cover rock conditions, KeTTHA developed a program combining multiple TBM drives with NATM methods at the inlet and outlet portals. After a detailed prequalification and bid process, SNUI JV was selected in 2009 as the contractor for the project - a consortium of Shimizu Corporation and Nishimatsu Construction of Japan, along with local companies IJM Corp. and UEM Builders Bhd. The JV is now operating 3 Robbins Main Beam TBMs, each excavating tunnel sections ranging from 11.3 to 11.8 km in length, in mountainous areas outside the city.

Tunnelling Methods

While vertical tunnel walls were specified in short sections of NATM excavation (ranging from 1.9 to 2.6 km each), the tunnel length and geology, consisting of granites with approx. 50 to 200 MPa UCS, prevented using drill and blast for the main drive. “In this type of hard rock, we prefer to use Robbins TBMs. The total contract construction time is 5 years and the tunnel is quite long, so drill and blast could not have done this in the time specified,” said Ohashi, Mechanical Engineer for SNUI JV.

The contractor’s experience with Robbins TBMs also helped them to narrow down a decision. “When I worked in Hong Kong in 1998, I used a TBM of this manufacturer on a tunneling project, so this is my second time using a Robbins machine. I have used other machines, but this design is simpler and easier to use, and more powerful,” said Nakano, Deputy Project Manager for the SNUI JV.

Hard Rock Machines, High-Tech Design

To tackle the high cover, hard rock conditions, the 3 machines were designed with unique design aspects - from custom cutterheads to streamlined operator’s cabs. The TBMs were engineered with the smallest diameter back-loading cutterheads ever to be mounted with 19-inch disc cutters. The back-loading design increases safety and efficiency during cutter changes, as workers are not exposed to the tunnel face. The larger cutter diameter also aids in increased cutter life and higher advance rates in hard rock, compared to 17-inch diameter cutters.

Cutter Monitoring

Not only is the cutterhead design novel, but the cutters themselves are being continuously analyzed using Robbins’ new cutter monitoring system. The wireless system keeps track of several variables on each cutter, including cutter rotation, temperature, and vibration.

Following some design modifications, the monitors have been installed on the 19-inch face and gage cutters of 1 of the 3 TBMs, with installations planned on the other 2 TBMs shortly. Each cutter is equipped with a sensor bolted inside the cutter housing, allowing raw data to be sent to a program display in the operator’s cabin. “The new system allows contractors to plan cutter changes, because they know when one cutter becomes blocked and stops rotating, creating a higher load on the adjacent state of wear of all their cutters. They are also aware of sudden cutter failures through increases in temperature or failed rotation,” said Steve Smading, Cutter Product Manager.

Touch Screens and Wireless Operation

Operator’s cabs on each of the 3 machines include industrial computer systems and wireless routers. The routers allow for laptop access to control systems from any location on the TBM, and allow for remote access of the Programmable Logic Controller (PLC). Integrated touch screens are another feature of the cab designs. Dual Central Processing Units (CPUs) provide both an operating and standby system for machine control, while Closed-Circuit Television (CCTV), data logging, and laser guidance systems are all accessible and adjustable via the screens.

Due to the system integration and ethernet connection, all data can be transmitted to the surface via fiber optic cables for viewing. “We have been keeping all real-time data on our servers. These are in our site offices, and there is one in Tokyo, which then routes the data on the internet. Because of this our actual progress data is available anywhere in the world from our password-protected website,” said Nakano.

Novel Ground Support

While the ground support program varies from steel straps to rock bolts based on the rock classification, the majority of primary support is being done using a novel type of shotcrete. The shotcrete is applied manually and consists of a continuous mixing and charging pump system, customized dry mortar mix with polypropylene fibers, and a fast-acting accelerator. The shotcrete, developed by MCM Co., Ltd. and DENKA of Japan, has been used on numerous TBM and NATM projects in Japan, though this is the first time the system has been used internationally. “The dry mix system is advantageous because it can be started and stopped whenever necessary, and can be mounted in the TBM back-up. Wet systems, by comparison, generate unused mortar if frequently started and stopped, requiring downtime for cleaning,” said Nobuo Suematsu, MCM Co., Ltd.

MCM and DENKA worked with Robbins to create a near-zero rebound L1 shotcrete system to be used as the primary means of ground support. The shotcrete is applied following each TBM stroke in a 2 cm layer directly behind the cutterhead support, and is accompanied by ring beams depending on the ground conditions. Compressive strength of up to 15 MPa is achieved within 24 hours of application. “The shotcrete is very quick setting with no rebound, and the mortar does not require high pressure application,” said Nakano.

Continuous Conveyors

Three Robbins fabric belt continuous conveyors are operating simultaneously behind the TBMs, a setup that was the only way to maximize efficiency, according to Nakano: “We considered muck cars and rubber-tired trucks early on, but the tunnel diameter is too small for trucks, and muck cars would take too much time out of the schedule. This is because the diameter is so small; we couldn’t make a double track. Conveyor was our only choice. The extension time for the conveyor is very short, so this is a big advantage for us.” The belt is added every 8 to 10 days, a process that takes 10 to 12 hours and is paired with TBM maintenance and cutter inspections.

At the time of writing the conveyors were operating with good availability, averaging at 92 % with few problems. “We like the continuous conveyor because we can bore without interruptions, so we can make good progress,” said Mito, Chief Engineer for Shimizu Corporation at the Adit 4 site.

Wide Ranging Jobsites Adit 2 to 4

The 3 TBMs were assembled Shanghai, China and shipped to Port Klang, where they were then trucked to each portal location. The most remote of these locations is high up in the densely forested hills near the town of Karak, about 45 km from downtown Kuala Lumpur. Personnel at the remote Karak site, also known as Adit 2, mentioned seeing cobras, monkeys, and the occasional tiger in the surrounding areas. Supplies including pre-cast invert segments are trucked to the site each day. “Everything is shipped in from the other jobsites or suppliers in the city. We have nothing stored onsite except fresh water for the tunnel,” said Glen Maynard, Robbins site manager at Karak.

Geology at the Adit 2 site consists of weathered granite with warm water inflows up to 13,000 l per minute from hot springs. “We have a section of weathered rock, and this combined with the water inflows is a challenge because we are tunneling downhill,” said Maynard. The contractor is using spiling methods combined with grouting to reduce over-break and lessen the water inflows. “We are also managing these inflows by upgrading our pumping capacity from 20,000 to 30,000 l,” said Nakano.

The Adit 2 tunnel, at a 10 % downgrade, travels through variable weathered granite up to 200 MPa UCS. While the water is currently a comfortably warm temperature, sections under higher cover could see water inflows approaching 37°C.

To mitigate risks, the SNUI JV has adopted a program of continuous probe drilling, along with a contractor-developed add-on known as the DRIS system, installed on all 3 TBMs. The DRIS calculates the rate of advance using drill feed pressure, rotation, and other variables, and also infers the rock quality based on the rate of penetration. The Adit 2 site is currently on track for a breakthrough in the first quarter of 2013 - as of March 2012, the TBM had advanced 4.4 km.

Adits 3 and 4 are located southeast of downtown Kuala Lumpur, in the Hulu Langat district. TBM tunnelling at Adit 3 began in good ground conditions, but quickly entered a section of heavily faulted, relatively soft in which a void of more than 50 m high was encountered. The near-zero rebound shotcrete was used successfully to overcome this section. More recently, the TBM has met with rock above 200 MPa UCS, and with at least 30 % quartz content.

To cope with the abrasive rock conditions, crews perform daily cutter inspections. “We measure each cutter using a cutter gage every morning to determine wear and decide which cutters to change. We feel comfortable doing this inside the back-loading cutterhead, which is much safer than front-loading and makes cutter installation easier,” said Birch. By Spring 2012, the machine had advanced approx. 4.5 km.

Also located in the Hulu Langat area, Adit 4 has seen the fastest advance rates, up to 721 m per month. Though the rock strength is softer in this section, it has the tendency to become blocky and a stretch of completely weathered rock with soil-like ground was encountered during tunnelling last year. Shotcrete was again successful in consolidating this section. Despite challenges, the Adit 4 TBM is on schedule for completion at the end of 2012. The TBM has to date excavated approx. 6.7 km or about 60 % of the tunnel length.

Quality in Tunnelling

As of Spring 2012, overall tunnelling is more than 50 % complete and proceeding on schedule. In 2011, the contractor also received a recognition award from the Malaysian government, for excellence in safety and environment. “We’re all very proud of the achievement. Crews are well-informed at meetings each day, which goes a long way towards maintaining safe working conditions,” said Maynard. Robbins training classes were also held before the start of the project to instruct operators and the JV on safe TBM operation. “Our crew worked together with the training team, and they gave good professional advice to us,” said Nakano.

Environmental cleanliness was in part recognized because of the shotcrete delivery system. “The shotcrete offers environmental benefits, because it is transported in sealed cars without exposure to the surroundings,” said Birch. Bonding, according to Birch, has been good and rebound has been minimized compared with standard shotcrete mixtures.

The shotcrete system has so far saved the excavation a significant amount of time compared to conventional ground support. In the somewhat fractured ground conditions currently being encountered, the machines would have required an estimated 2 hours of ground support work per excavated meter with conventional methods. This would have added up to 210 days to excavate and support the type C ground. With the near-zero rebound system this time has been reduced to 158 days -a time savings of 52 days.

Overall, the TBMs are maintaining their schedule despite difficult ground conditions and remote locations. SNUI JV is proud of the accomplishments to date. “So far, the TBMs have had pretty good performance, but we still have much of the tunnel remaining,” said Ohashi.