Special Dumper convinces during Try-outs

A new dumper “made in Germany” with a capacity of 25 t was introduced at the bauma in Munich last year by the family business from Meppen run by the owner. According to the manufacturer, after a successful debut at the fair with an overall positive resonance during and after the bauma, the articulated 2-axle dumper has undergone extensive application tests on various building sites.

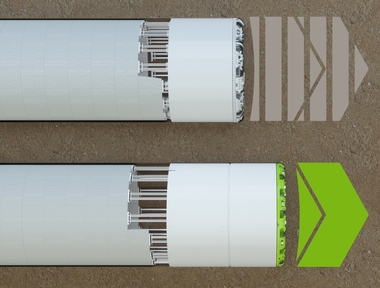

The efficacy of the Tunnel Dumper 5025 was tested on roads as well as in rail and Metro tunnels and thoroughly satisfied those using it. The high economy of this transport concept was underlined by the removal of time-consuming turning manoeuvres, the low fuel consumption and the extremely low ventilation requirement in this category.

The advantages of the new vehicle concept result by and large from the compact dimensions in conjunction with the rotating operator cabin and the efficient drive train with an output of only 194 KW, thus fulfilling current emission levels.

During development, the focus centered on the dumper’s efficient operation as well as especially on working efficiency and the operator’s field of vision. Thus the rotating driver’s cabin with 2 identically set-up cockpits in conjunction with the deep-lying trough edge affords ideal sight conditions in both directions of travel.

During the application tests, operators also praised safe access to service and maintenance points. The outstanding driving comfort enhanced by the articulated link in conjunction with suspended front axle facilitates considerably higher driving speeds and non-fatiguing work even given poor road conditions.

The concept presented here was devised in close collaboration with users. It underlines the force of innovation and the capabilities of the Bergmann Company.