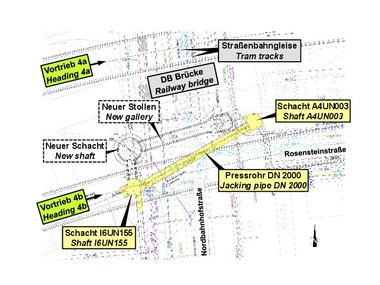

Rectangular Pipe Jacking

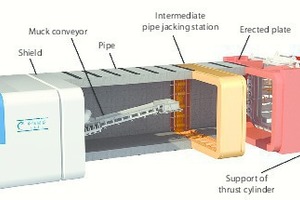

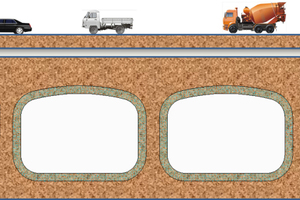

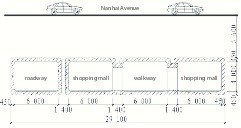

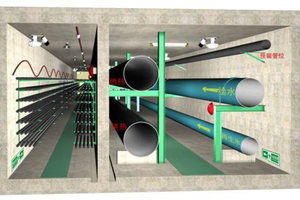

In case of shorter tunnels or smaller underground structures in urban areas, most of the construction projects employ the cut-and-cover method. This method bears a couple of disadvantages, such as interruption of traffic, requirement of extensive additional measures to stabilize surrounding buildings, emission of dust and noise. To reduce these side effects of construction activities, the application of rectangular pipe jacking excavation has been developed. As common in conventional pipe

jacking, a small launch and receipt shaft must be excavated, which can usually be done

without traffic closing.

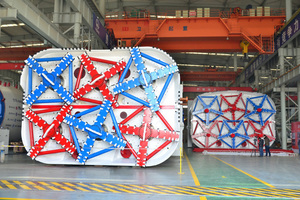

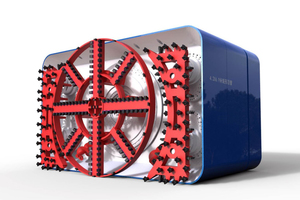

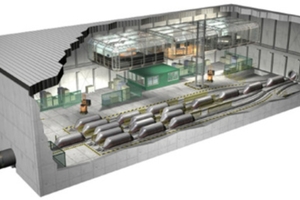

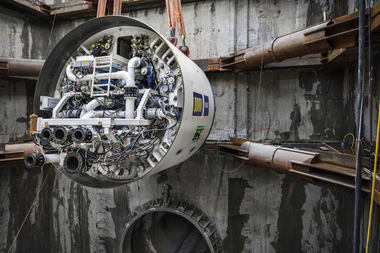

Machine Design

In the 1970s rectangular pipe jacking was developed and successfully applied for the first time in a Tokyo underground passage. After several years’ research and development, rectangular pipe jacking construction technology with widths of more than 6 m and heights exceeding 3 m became popular in Asia. At present, rectangular pipe jacking is applicable in a range of soil stratum and weak rock stratum (UCS: 0 to 10 MPa), with Earth Pressure Balance (EPB) excavation mode.

EPB rectangular pipe jacking machines consist of cutter head, drive system, shield structure, screw conveyor,...