Pressure Exchange System: Cooling Technology for working Underground

The opening of the Gotthard Base Tunnel on June 1, 2016 is an occasion for Siemag Tecberg to reflect on a project that involved unique challenges. The shaft hoisting system in the Sedrun part-section was built by Siemag Tecberg, who also operated the system during the construction phase. The hoisting plant was a critical logistical resource providing the means of access for construction supplies and of removal for the excavated material for the 8.5 km central section, which was driven by drill+blast.

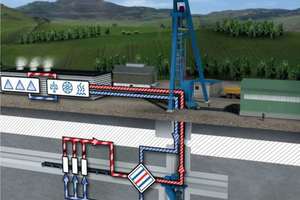

The cooling for the underground worksite was provided by a further Siemag Tecberg technology, in the form of the “Pressure Exchange System” (P.E.S.). The P.E.S. has the function for efficiently supplying the underground cooling network with cold water from the surface.

Primarily the P.E.S. was developed for mining applications; this technology has a strong reputation in the sector, which is reflected by numerous references. As the example of the Gotthard Base Tunnel demonstrates, the technology can be applied to other sectors such as tunnelling.

The P.E.S. is a central element in the Sedrun mid-section cooling facility. It forms the interface between the high-pressure water circuit and the low-pressure water circuit. The high-pressure circuit connects the main cooling facility on the surface with the Pressure Exchange System located in the tunnel. From there, the low-pressure circuit connects the P.E.S. with the underground coolers, delivering cold water around the system.

The use of a P.E.S. in this type of application has several technical advantages, particularly to the low temperature loss achievable, which benefits whole system efficiency.

A detailed article on the P.E.S. technology will be presented in detail in tunnel at a future date.