Mission accomplished: Crossrail Tunnelling concludes

With the breakthrough of Crossrail’s tunnel boring machine Victoria at Farringdon Station on May 23 at 5.30 am, London has made tunnelling history: Victoria is the last of eight Herrenknecht TBMs which together have dug 42 km of tunnels right through the heart of the English capital within three years, from May 2012 to May 2015. Crossrail will form a major new east-west connection through the congested metropolis of eight million inhabitants once the five twin bore tunnels with a total length of 21 km and ten new stations will be put into operation to link existing railway networks to the east and west of London.

Crossrail is 65 % complete

Project owner Crossrail Ltd (CRL) commissioned three UK/European joint ventures with the construction of the five tunnel sections: Bam/Ferrovial/Kier JV with the Western Tunnels, Dragados/Sisk JV with the three sections of the Eastern Tunnels and Hochtief /Murphy JV with the Thames Tunnel. Herrenknecht supplied six Earth Pressure Balance Shields (EPB) for the construction of the eastern and western tunnels through London clay, sand and gravel. Two Herrenknecht Mixshields excavated the Thames Tunnel at depths of up to 15 m below the river bed.

At depths of up to 42 m the tunnel boring machines made their way under some of the most expensive real estate in the world past existing metro lines, sewerage, supply and disposal channels as well as building foundations. The machines with a shield diameter of 7.08 m are 147 m long, weigh up to 1100 t and have a drive power of up to 1920 kW.

Operated by 20 men per shift, twelve men on the TBM, eight on the gantry and above ground, the machines drove 24 hours a day, seven days a week. They achieved impressive advance rates of up to 72 m and 45 segment rings per day (TBM Ellie on 16 April 2014 between Pudding Mill Lane and Stepney Green). On average Crossrail tunneling progressd at a rate of 38 m per day

Andrew Wolstenholme OBE, Crossrail Chief Executive, praised the teams on the completion of the work on time and within budget. “The challenge now shifts to the complicated and substantial task of fitting out the tunnels and stations to enable Crossrail services to operate,” said Wolstenholme. With the end of the mechanized tunneling operations, the Crossrail programme is 65 % complete.

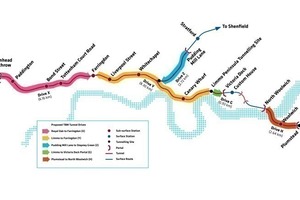

Five twin-bore tunnel drives were undertaken to construct Crossrail’s tunnels:

Royal Oak to Farringdon – length of drive approximately 6.8 km

Limmo to Farringdon – length of drive approximately 8.3 km

Pudding Mill Lane to Stepney Green – length of drive

approximately 2.7 km

Limmo to Victoria Dock Portal – length of drive

approximately 0.9 km

Plumstead to North Woolwich – length of drive

approximately 2.9 km

What happened to each of the TBMs?

Similar to the TBMs Mary, Sophia, Jessica, Ellie, Phyllis and Ada, the remaining machines Victoria and Elizabeth will now be dismantled. Their 130 m trailers will be removed from the tunnel via the shaft at Stepney Green and returned to manufacturer Herrenknecht, with parts recycled for future tunnelling projects. The cutterheads will be cut into small pieces and removed via the shaft at Farringdon. The front “cans” of each machine will be left in the tunnel, and Crossrail trains will pass through them when services begin in 2018.

Europe‘s largest infrastructure

construction site – until 2018

Crossrail will be a new 118 km metro railway from Reading and Heathrow in the west to Shenfield and Abbey Wood in the east via central London. The journey time from London Heathrow to the main financial centre in the City of London (Liverpool Street) will be shortened from 55 to 32 minutes. 200 million passengers per year are expected.

To deliver the Crossrail project up to 10 000 workers are active on more than 40 jobsites. Construction started in 2009, the start-up is scheduled for the end of 2018. The total costs amount to approximately 20.8 billion euros.