Küblis Tunnel opened after Eight Years of Construction

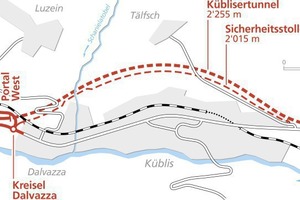

At the end of June 2016, the 3350 m long Küblis bypass between Dalvazza and Prada was opened to traffic in the Canton of Graubünden in Switzerland. As a result the municipality Küblis has been relieved of the traffic carried by the A28 national highway between Dalvazza and Selfranga. The 2255 m long, bi-directional Küblis Tunnel with two lanes constitutes the main element of this bypass. including a parallel, 2015 m long safety tunnel at a gap of 30 m, which is connected by cross-passages to the Küblis Tunnel at 230–290 m intervals.

Nearly five years after construction began in May 2008, the tunnel breakthrough was celebrated in March 2013. After the inner lining was installed including the electromechanical facilities, it was commissioned this year according to schedule. The costs for the tunnel amounting to roughly 210 million Swiss francs (190 million euros) have also remained within the projected limits.

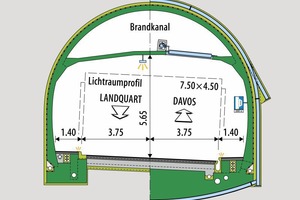

The tunnel runs in the direction of the east portal at gradient of up to 4.6 %; the standard profile of the tunnel in the rock sections is horseshoe-shaped, with 3.5 m clearance height, 7.5 m carriageway width as well as 1.4 m wide shoulders at each side. There are also bays installed at both sides of the tunnel walls.

Altogether 265 m was produced by cut-and-cover at the two portals; the part of the Küblis Tunnel excavated by applying the conventional method is 1890 m long, with a maximum overburden of 140 m and was driven on the rise by drill and blast like the parallel safety tunnel.

Simultaneous Construction Processes

The tunnel was provided with a 30 cm thick waterproofed inner arch; the inner shell was reinforced in sections with unfavourable geological conditions and rounded off with a base invert. The safety tunnel is mainly a monocoque structure with steel fibre shotcrete and rock bolts; when required, steel inserts were installed for reinforcing purposes.

At the same time as the inner lining in the western tunnel half was produced, the further support operations (carriageway surface, tunnel coating, installation of the operating and safety equipment) were planned and executed in the eastern half. This entailed getting the safety tunnel ready as soon as possible for industrial safety reasons.

Thanks to the gradual commissioning of the safety systems that were needed in any case for subsequent operation, it was possible to enhance safety for the suppliers and reduce construction time by roughly half a year without involving any additional costs.

Crossing Schanielatobel

The crossing of the Schanielatobel landfill turned out to be an especially sophisticated task, as here the tunnel passes through a channel filled with soft ground given overburden of only 5 m. The tunnel and safety tunnel were driven in this route section protected by a piling wall through employing the top-down method.

Safety Installations

38.3 million Swiss francs (around 35 million euros) was invested in the Küblis Tunnel’s safety installations. The systems that were installed correspond to the latest state of the art. The incident detection system is capable of identifying all incidents and traffic states that occur. Thus for instance, the video system can tell whether persons or animals are in the tunnel; an alarm is also triggered in the corresponding control centres in the event of vehicles driving far too slowly, slowing to a halt or stopping in the bays.

Fires can be identified and precisely localised by smoke alarms and a cable on the tunnel ceiling that responds to temperature. The two axial fans are automatically revved up to maximum load in the Dalvazza ventilation and electric control centre, and the three exhaust air flaps nearest the incident open. Fire gases are suctioned off through the flaps at a rate of roughly 250 m³ per second and are released through the exhaust air duct via the tunnel ceiling and exhaust air stack. In this way, the gases are not distributed throughout the tunnel.

The routes to the escape doors leading to the safety tunnel are marked and provided with emergency lighting. Constant overpressure prevails in the safety tunnel so that the possible penetration of smoke is avoided. In addition to its key lighting the tunnel also possesses signals at the entrance and for the carriageway; in this way, further accesses can be prevented should an incident occur so that emergency services can reach their destination from both sides.

G. B.