Hiroshima Heavyweight launches on Expressway Line 5

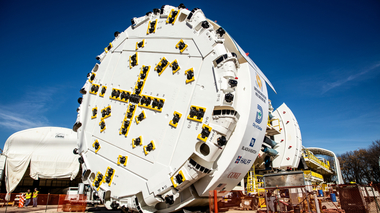

On September 18, 2018, a Robbins slurry machine, measuring 13.7 m in diameter, made its first cut into hard rockOn September 18, 2018, a Robbins slurry machine, measuring 13.7 m in diameter, made its first cut into hard rock for the Hiroshima Expressway Line 5 project in Japan. The launch at an urban jobsite was made possible by Onsite First Time Assembly (OFTA) of the TBM. The contractor, a joint venture of Obayashi-Taisei-Kosei, had a strict timeline of eight months to adhere to when it came to machine assembly. “This deadline was very important. After assembling the TBM, I think OFTA was appropriate for this project,” said Mr. Ryota Akai, Deputy Project Manager for the Obayashi JV.

Due to the project location there were also restrictions on delivering the TBM—in order to meet controlled transportation limits within the city, the TBM had to be divided into small transportable weights and sizes, then assembled in a small jobsite, 30 m wide and 60 m long. The 2400 metric ton machine will bore 1.4 km of the 1.8 km long tunnel that, once completed, will significantly improve traffic conditions in Hiroshima. The new Expressway Line 5 tunnel will directly connect Hiroshima’s urban area with a major national highway network and is expected to improve access to Hiroshima Airport. Tunnel completion is planned for 2020.

The massive machine is the country’s first foreign-made large diameter Slurry TBM to excavate hard rock in Japan. The machine is expected to encounter granite with rock strengths up to 130 MPa UCS. Those involved in the project are excited to see what effect this will have on how Slurry TBMs are used in the future.

The design of the Slurry machine is robust in anticipation of potentially abrasive rock conditions and water pressures up to 13 bars. In preparation for the conditions, the machine was designed for 20-bar water pressure. The robust cutterhead was fitted with 20-inch and 17-inch diameter pressure compensating cutters, which utilize a patented design to effectively operate under high pressure. The joint venture intends to change the disc cutters an estimated 10 times during the bore as part of the machine’s maintenance.