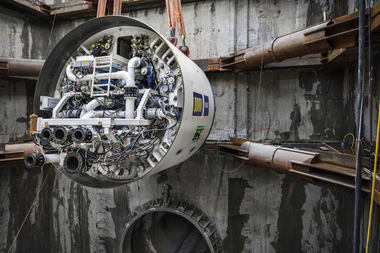

Grooved mechanical Piping Systems in Tunnels

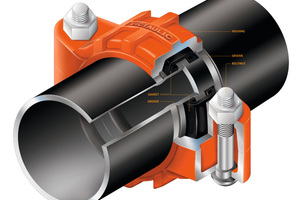

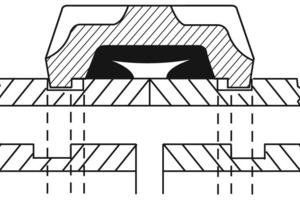

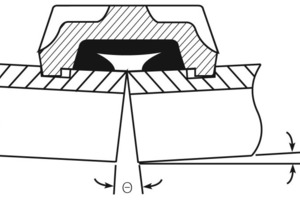

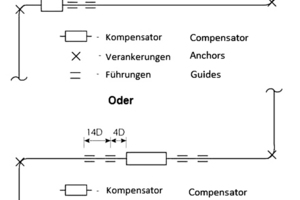

The installation of pipework systems in tunnels often represents a particular challenge. Grooved mechanical pipe-joining systems are a safe and effective solution. This report deals with the basic set-up of grooved mechanical coupling systems, featuring in particular the angular displacement and linear movements, movements resulting from thermal conditions and expansion bends. In addition, international examples of application are cited.

Introduction

Pipelines for various purposes are needed in tunnels such as:

During the construction phase to supply tunnelling machines with compressed air and water and to remove muck.

During the operational phase as supply and disposal lines for extinguishing water, heating, air-conditioning and industrial water.

Generally tunnels are long, seldom straight and frequently difficult to access. Installing pipework in tunnels represents a particular challenge especially as curves, changes in direction as well as restricted installation periods, a lack of space for installation, tricky surrounding...