Economic Efficiency of Fixed Fire Fighting Systems for Road Tunnels

In the past, tunnel fires have often led to major structural damage, and the tunnel had to be closed for a long time to repair the damage. Not only the repair costs, but also the unavailability led to high financial burdens for the operators and the national economy. Suitable fire protection measures, which on the one hand increase the safety of traffic participants, can on the other hand also improve the availability of the infrastructure. In particular, fire protection boards and fire fighting systems, which are not required by German regulations, repeatedly lead to discussions about their economic efficiency in this regard. Therefore, this article compares the economic efficiency of different fire protection measures on the basis of their life cycle costs. The focus here is on water mist fixed fire fighting systems.

Prerequisites

According to the current German regulations [1], structural fire protection in road tunnels should essentially be realised by adding polypropylene fibres to the structural concrete (PP fibre concrete) of the tunnel inner shell. Only for tunnels for which a fire could have serious effects on the stability, separate measures are to be specified. In such cases, the surfaces of the inner lining were usually clad with fire protection boards in the past.

Although the improvement of fire protection by means of technical installations is being implemented more and more frequently internationally, in Germany there are still reservations about the economic viability of a fire-fighting system designed for this purpose. Therefore, this article compares the life cycle costs of three variants: a tunnel without additional fire protection, one with passive fire protection (fire protection boards) and one with active fire protection (water mist fixed fire fighting system/WM FFFS).

An economic feasibility study on the use of fire protection boards in tunnel structures has already been carried out and published [2, 3]. Both the initial and the follow-up costs for a modelled tunnel were determined and compared with an unprotected tunnel for a fire event. These calculations are now to be supplemented here by the economic feasibility study of a WM FFFS. The results are based on the same assumptions as those in the cited calculation (two-way tunnel, length 1000 m, circular cross-section, 10.5 m diameter RQ 10.5 T).

Working Principle of Fire Protection Boards

Fire protection boards are attached to the inside of the tunnel lining. In the event of a fire, they protect the concrete from a rapid increase in temperature and, in particular, from the resulting spalling of the concrete. Due to this „thermal insulation“, the heat released by the fire is not dissipated into the walls and ceiling, so that the temperatures in the tunnel in the event of a fire are higher than without fire protection boards [4]. Boards damaged by a fire have to be replaced.

Although fire protection boards efficiently protect the concrete and the load-bearing tunnel structure, they do not actually serve to fight the fire and therefore do not support the work of the emergency response teams in the event of an incident. However, they do provide good protection against falling concrete fragments. Due to the high heat development in the tunnel tube during a fire, it can be assumed that damage will occur to the electrical installations in the fire area, which therefore usually have to be repaired or replaced at least in this area.

Working Principle of Fixed Fire Fighting Systems

In contrast to fire protection boards, WM FFFS primarily fight the fire and prevent or reduce its spread. In addition, they also significantly reduce the ambient temperatures in the tunnel and the amount of smoke gas. This supports the emergency services in fighting the fire, protects the tunnel structure and its operating equipment, and often improves escape conditions [5].

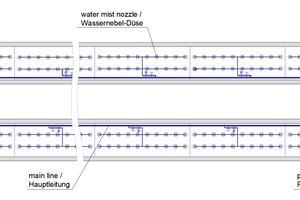

A WM FFFS essentially consists of a network of piping with nozzles distributed along the length of the tunnel, which is supplied with water from a pumping station. In the event of a fire, three adjacent sections are usually activated to fight the fire with water mist and prevent the fire from spreading to other vehicles [6]. The effectiveness of WM FFFS has already been proven in numerous full scale fire tests carried out within the framework of research projects (e.g. SOLIT1 [7], SOLIT2 [6], UPTUN [8]) and in project-specific investigations (e.g. Dartford Tunnel [9]).

In the case of tunnel fires, it has been shown that when a WM FFFS is used in the event of a fire, the damage to the structure is minimal and the tunnel can usually be reopened to traffic within a short time.

Fire Incidents in Tunnels Equipped With Fire Protection Boards

Rannersdorf Tunnel (Austria)

In 2018, the Vösendorf Tunnel and the Rannersdorf Tunnels (partially) were equipped with fire protection boards [10]. On 29 April 2019, a truck (tractor unit including trailer) burnt out completely in the Rannersdorf Tunnel. The cause was presumably a technical defect on the vehicle [11]. The tunnel was damaged over a length of approx. 600 m and had to be closed for about one month for the most important repairs. Over a length of 15 m, the tunnel ceiling had to be completely removed and replaced over an area of 300 m² [12]; it was apparently not protected by fire protection boards in this area. The complete renovation of the tunnel could only be completed about 5 months after the fire event. The safety features and electrical fittings had also been damaged in the fire and had to be renewed. The operator ASFINAG puts the cost of the renovation alone at almost 3 million euros [12]. This does not include the losses due to lost toll earnings and economic costs.

Elbe Tunnel Hamburg (Germany)

On 31 March 2011, there was a truck fire in a tube of the Elbe tunnel in Hamburg. The tractor unit of a team loaded with 28 tonnes of wheat caught fire in the middle of the tunnel [13]. The tunnel, which was lined with fire protection boards, was damaged over a length of 50 m, but the fire had not caused any structurally relevant damage to the tunnel structure. The asphalt in the tube had to be renewed. The walls were renovated and the fire protection boards on the ceiling were replaced. The entire electrical fittings had to be repaired over a length of 50 m. After about 10 days, the tube could be reopened [14, 15].

Fire Incidents in Tunnels With Fixed Fire Fighting Systems

Burnley Tunnel (Australia)

On 23 March 2007, a rear-end collision involving three trucks and four cars resulted in an explosion and fire in the 3.4 km Burnley Tunnel [16]. Immediate activation of the fixed fire fighting system (FFFS) contained the flames and prevented a flashover to other vehicles and significant fire spread [17]. One hour after the fire had broken out, it was extinguished; four days later, the affected tube was reopened to traffic. There was some minor damage that could be repaired rather easily [18].

In the same tunnel, vehicles caught fire again on 22 October 2018, as well as on 11 June 2019. In both cases, the fire brigade was able to extinguish the fire with the support of the immediately activated FFFS and reopen the tunnel to traffic in a short time [19, 20].

Arlberg Tunnel (Austria)

On 29 January 2019, a car on a car transporter loaded with several cars caught fire. The fire spread rapidly and also spread to the truck [21, 22]. The motorway police suspect that a technical defect [23] was the cause of the fire. Due to the automatic activation of the WM FFFS installed in the tunnel, the fire was contained and eventually extinguished by the fire brigade about 30 minutes after it started. About two hours later, the tunnel was completely reopened. No damage to the structure and safety installations had been detected.

Dartford Crossing (England)

On 2 July 2016, a car caught fire in the Dartford Tunnel, which is made of cast iron tubbings and runs under the Thames. The WM FFFS, which was immediately activated, was able to prevent the fire from spreading to other vehicles and to contain the fire. The fire was subsequently extinguished by the fire brigade. The tunnel could be opened to traffic after about 90 minutes. There was no damage to the tunnel or the safety equipment.

A few months later, another car caught fire. The WM FFFS was automatically activated without delay and was again able to prevent a flashover. The tunnel was reopened 83 minutes after the fire was detected, and no damage to the structure was found [24].

During the preparation of this article, no fire incidents in tunnels with FFFS could be researched in which major damage or longer closure times occurred due to or after a fire.

Comparison of Life Cycle Costs

Decisions for possible variants in construction projects should in principle not only be made on the basis of the construction costs, but also take into account the costs that arise during the utilisation phase, which is usually very long as far as tunnels are concerned. According to a recommendation of the DAUB (German Tunnelling Committee), an investment decision should therefore be made on the basis of a life cycle cost analysis [30]. Such an analysis takes into account not only the initial costs (production), but also the subsequent costs (operation, maintenance and renovation). The calculation considers both the service life of individual components and their replacement, as well as the calculation interest rate with which the amounts are compounded or discounted.

Even though the European Central Bank has been holding the current key interest rate (mid-2021) at the record low of 0.0% since March 2016, a real interest rate of 1.7% p.a. was used for the calculations – as provided for in the German Federal Transport Infrastructure Plan 2030 [31] for calculations of life cycle costs. In long periods of observation, such as in this case 100 years, the inflation rate also has an influence on the price development. Given a uniform change in all prices, however, it does not have to be taken into account, since a uniform price level change occurs for all payments. In addition, the uncertainties associated with estimating the inflation rate are greater than the expected gain in accuracy [32]. Therefore, the „actual value approach“ is used in this study and inflation is not taken into account.

For the calculation of the initial and follow-up costs, the same exemplary tunnel is used as in the above-mentioned economic feasibility study for fire protection boards [2, 3] (two-way tunnel, length 1000 m, circular cross-section, 10.5 m diameter RQ 10.5 T). Furthermore, it is equally assumed that a fire event occurs at the beginning of the utilisation phase, resulting in costs for its repair, as well as a toll loss and economic costs due to detour-related route and travel time extensions resulting from the temporary unavailability. The results can thus be compared directly.

Initial and Follow-Up Costs of a WM FFFS

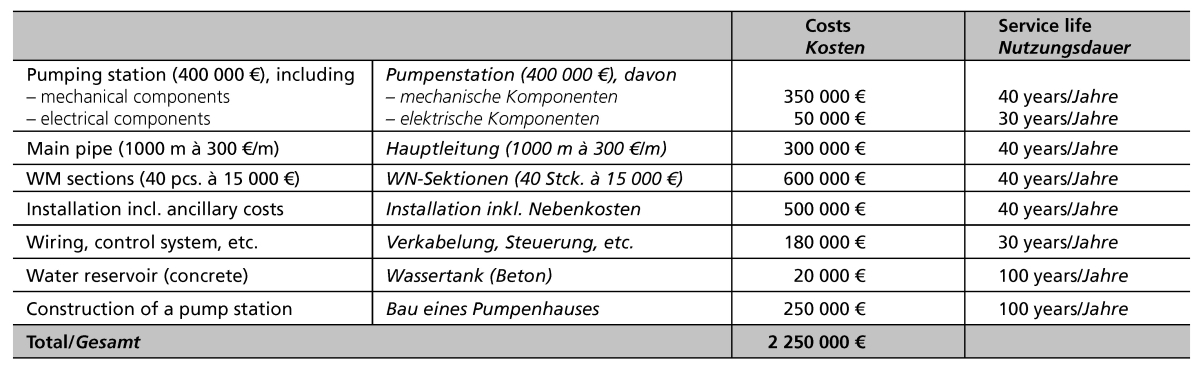

The WM FFFS for the exemplary tunnel essentially consists of a pumping station, a main pipe and a piping network with 40 water mist sections of 25 m each. Furthermore, a separate operations building is taken into account, although in many cases this may be part of other building structures. The initial costs (manufacturing costs incl. installation) of a WM FFFS including the calculated service life are listed in Table 1.

Table 1: Initial costs of a water mist fixed fire fighting system

Table 1: Initial costs of a water mist fixed fire fighting system

This total cost analysis of a tunnel with WM FFFS do not include the possibility of cost savings through compensatory measures such as the reduction of the design fire size. In numerous international tunnel construction projects, such savings have been realised. The reduction of the design fire size has, for example, positive effects on ventilation, structural fire protection, the permissible time for the fire brigade to arrive, the saving of insurance costs, etc. Further information can be found, for example, in the results of the SOLIT2 project [6] or the latest versions of the guidelines NFPA 502 [25], RVS 09.02.51 [26] and the publications of PIARC [5].

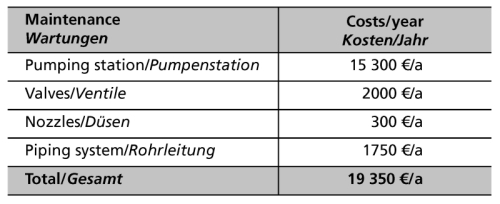

The maintenance work for WM FFFS was determined using the specifications of the SOLIT guideline [6] and based on manufacturer specifications. Through technical optimisation of system components, essential maintenance work can be carried out without additional tunnel closures. Table 2 gives an overview of maintenance costs for modern WM FFFS.

Table 2: Maintenance costs of a WM FFFS [27]

Table 2: Maintenance costs of a WM FFFS [27]

The calculation of the life cycle costs for an assumed tunnel service life of 100 years, taking into account the above-mentioned initial and maintenance costs as well as the calculation interest rate of 1.7% p.a., leads to total costs of 4 591 900 euros.

Initial and Follow-Up Costs of Fire Protection Boards

The initial costs for the installation of fire protection boards for the exemplary tunnel consist of the material and installation costs (approx. 16 500 m² at 72 and 70 €/m²)

and amount to a total of 2.34 million euros (service life of 30 years) [2]. According to DIN 1076, part of the fire protection boards must be removed and re-installed at random as part of an inspection of the tunnel structure, which must be carried out every six years. For the resulting follow-up costs, a flat rate of 1.50 €/m² is applied for the total area. For this, total costs of approx. 24 740 euros are due every six years. Since tunnel maintenance must be carried out in any case, additional costs for the unavailability of the tunnel (loss of toll earnings) and economic costs were not taken into account. The total life cycle costs amount to 5 016 600 euros [2].

Damage Scenario: Truck Fire in a Tunnel With WM FFFS

The damage scenario „truck fire“ is selected with the cost-determining parameters in the same way as in the economic feasibility study for fire protection boards [2, 3]. In addition to the repair costs, direct effects of the tunnel closure (toll loss) as well as economic secondary effects due to the unavailability of the tunnel are considered. Some key assumptions are:

Average traffic of 24 900 vehicles/day

Average daily toll revenue of 4.50 €/vehicle

Costs for detour-related route and travel time extensions of approx. 417 800 €/day [2, 3] due to the tunnel‘s unavailability

If a fire occurs in a tunnel equipped with a WM FFFS, the WM FFFS is normally activated immediately after the fire is detected. Within 60 seconds of activation, the water mist is distributed in the three activated sections in the tunnel cross-section, i.e. over a length of around 75 m. This provides control of the fire, and temperatures as well as smoke gas are reduced. As the results from numerous real fire tests show, fire flashover to other vehicles is also prevented as a result [6]. In addition, active firefighting in the tunnel prevents major damage to the tunnel‘s structural design and operating technology. In addition, the fire brigade can reach the source of the fire (faster) in order to finally extinguish the fire.

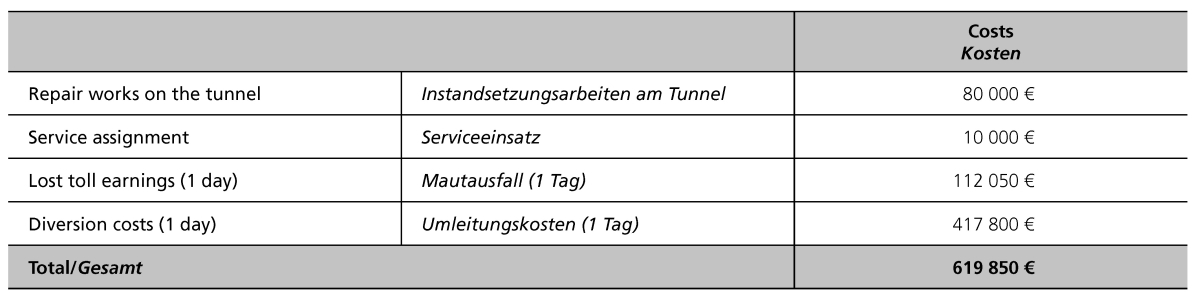

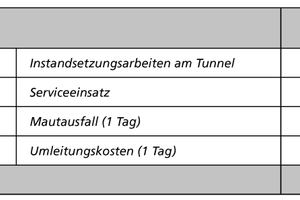

In most cases, longer-term tunnel closures could be avoided when WM FFFS was used and the tunnel was reopened to traffic within a few hours. Nevertheless, a 24-hour closure after the fire event is assumed here for investigations to be carried out. Even though in most cases active firefighting prevents damage to the tunnel structure, 80 000 euros were calculated for the repair. Costs for the inspection of the system after activation (service assignment) were also included in the calculation. Due to the prompt reopening of the tunnel, the lost tolls and the diversion costs in particular are comparatively low. The total costs are listed in Table 3.

Table 3: Costs due to a fire in a tunnel with WM FFFS

Table 3: Costs due to a fire in a tunnel with WM FFFS

Damage Scenario: Truck Fire in a Tunnel With Fire Protection Boards

In the economic feasibility study for fire protection boards [2, 3], the costs for a truck fire in a tunnel with and without fire protection boards have already been explained in detail. It was assumed that damage only occurred along a length of 80 m. For the repair, during which the tunnel is closed, 1.5 (with fire protection boards) or 7.3 months (without fire protection boards) were estimated. Costs for destroyed and repaired operating technology were not taken into account.

Comparison of Costs for the Damage Scenario Truck Fire

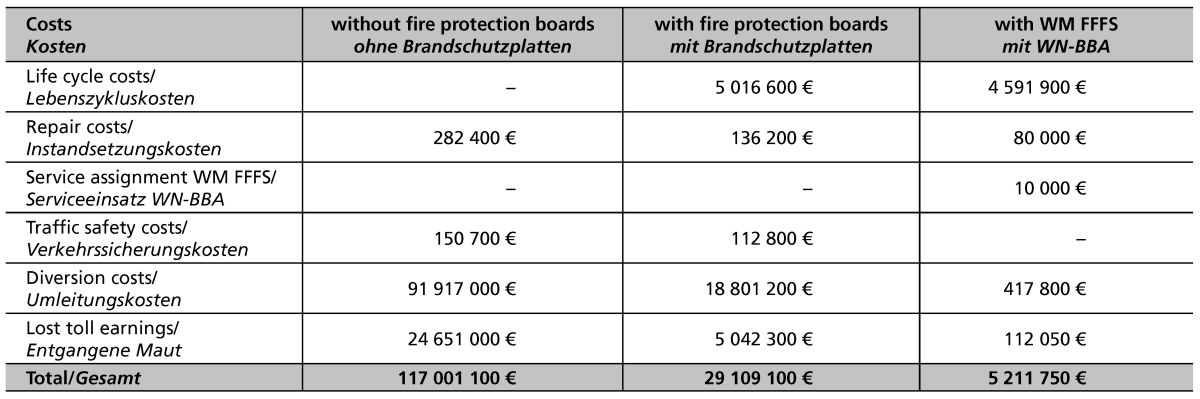

With the calculations carried out here and the economic feasibility study for fire protection boards already available, life cycle costs and total costs resulting from a truck fire are now available for three differently equipped tunnels (Table 4).

Table 4: Comparison of costs resulting from a truck fire in tunnels with different installations (columns 2 and 3 are taken from [2, 3])

Table 4: Comparison of costs resulting from a truck fire in tunnels with different installations (columns 2 and 3 are taken from [2, 3])

The initial costs for the tunnels with fire protection system are in a similar order of magnitude. They amount to about 2.34 million euros for the tunnel with fire protection boards and about 2.25 million euros for the one with WM FFFS. For the tunnel variant without additional fire protection systems, no initial costs are incurred. Based on the assumed service life of the tunnel of 100 years, the life cycle costs for the two fire protection variants (taking into account the calculation interest rate of 1.7% p.a.) are calculated at 5.0 million euros (fire protection boards) and 4.6 million euros (WM FFFS). The repair costs (including costs for service intervention) are lowest for the WM FFFS. Due to the short closure time of the tunnel in the WM FFFS variant, no traffic safety costs are incurred. Also due to the short closure time of the WM FFFS variant (1 day), the diversion costs and the lost tolls are significantly lower than for the variants without fire protection boards (7.3 months) and with fire protection boards (1.5 months).

The total costs (life cycle costs and costs in the event of only one truck fire over 100 years) are 117 million euros for the variant without fire protection boards, 29 million euros for the variant with fire protection boards and only 5.2 million euros for the variant with WM FFFS.

Discussion of the Results and Conclusion

The comparison of the three variants displayed in Table 4 clearly shows that the unavailability of a tunnel in particular leads to considerable costs for operators and users. The costs for the lost toll earnings are very high in the case of long closures, and the economic follow-up costs (diversion costs) resulting from the closure are extraordinarily high. Thus, it is of utmost importance to keep the tunnel closure times as short as possible after a fire incident. This is where the water mist fixed fire fighting system clearly shows its advantages: Active firefighting minimises the spread of the fire, and thus the damage in the tunnel – especially to the operating technology – is kept correspondingly low. This allows the tunnel to be put back into operation in a more timely manner, and the overall costs remain low. The more frequented a tunnel is and the more important it is for the general infrastructure, the more this applies. With only 24 900 vehicles per day, a tunnel with a relatively low traffic load was considered for the exemplary tunnel under investigation.

A fundamental difference between the fire protection measures considered can be seen in the protective effect: while fire protection boards prevent heat from escaping through the insulating effect of the boards in order to protect the building structure (concrete), a WM FFFS ensures that the fire gases are cooled, which has a positive effect on the entire tunnel tube. This also favours firefighting by the emergency services, because it often allows them to reach the scene of the fire in the first place. Large fires in tunnels without WM FFFS have shown that the emergency services were often unable to reach the source of the fire in order to quickly bring it under control due to the high temperatures, the strong heat radiation and the smoke gases that occur.

The cost consideration listed above – similar to the economic feasibility study for fire protection boards – did not include further cost benefits of using WM FFFS. For example, the construction of a new fire station at the north portal of the Elbe Tunnel amounts to approximately 9 million euros. Added to this are annual personnel costs of about 6 million euros [28, 29]. With the installation of a WM FFFS, significant costs could possibly be saved because the automatic activation of the system would also allow longer arrival times for the emergency services to be tolerated. It was also not considered that in the context of retrofitting, WM FFFSs usually do not require the tunnel to be closed during the day. This can significantly reduce economic costs already in the construction phase.

The calculations show that, in general, the costs of installing a WM FFFS are recouped over the service life if there is (at least) one major fire during this time. It is not possible to predict whether this will actually happen. However, the tunnel fire statistics of ASFINAG [33] suggest that this is very likely. Ultimately, it must be checked individually for each tunnel whether a WM FFFS or fire protection boards are recommendable from an economic point of view due to an increased probability of fire in the tunnel (e.g. location and length of the tunnel, proportion of heavy goods traffic as well as gradients in front of and in the tunnel) or a particularly high frequency and importance for the traffic network.

Water Mist Systems for Tunnels - Full Scale Fire Tests

![Table 2: Maintenance costs of a WM FFFS [27]](https://www.tunnel-online.info/imgs/1/6/9/1/8/8/5/tok_0330684b5bb66946e28dacece14a6326/w300_h200_x250_y102_fogtec-tabelle-2-3ac8c0e02121997d.jpeg)

![Table 4: Comparison of costs resulting from a truck fire in tunnels with different installations (columns 2 and 3 are taken from [2, 3])](https://www.tunnel-online.info/imgs/1/6/9/1/8/8/5/tok_6f082139f9dc6d2e8383fee1d89668a8/w300_h200_x600_y199_fogtec-tabelle-4-6c709dee74b0d668.jpeg)