Consequential Costs and Cost-Effectiveness of Fire ProtectionBoards Used in Tunnels

The STUVA Research Association for Tunnels and Transportation Facilities in Germany has carried out a study commissioned by and with the assistance of James Hardie Europe GmbH into the use of fire protection boards in tunnels. This investigation of the cost-effectiveness of fire protection boards in tunnels is not only concerned with investment and installation costs for the primary fire protection installation, it also includes the consequential and repair costs after a fire incident. The costs to the operator of traffic safety measures or lost toll earnings in case the tunnel has to be closed for a long time are also taken into account, as are the costs to the economy caused by diversions. The result: the initially higher costs for the installation of fire protection boards pay off as soon as a fire actually occurs in the tunnel during its service lifetime.

Fire Damage in Tunnels – Examples

Fires occur again and again in tunnels and often lead to serious damage to the structure with high repair costs. In the Austrian Gleinalm Tunnel for example, two fires occurred relatively soon one after another: in 2016, a small bus, and in 2018 a mobile crane with a weight of about 80 t caught fire. In both cases, large areas of concrete spalled at the tunnel ceiling due to the high temperatures. In order to repair the damaged concrete, the tunnel had to be completely closed for one month in the first case and for two months in the second case. The repair costs after the first fire were about 0.5 million, and after the second fire 2.7–3 million euros. Much higher however were the financial losses to the operator: while the lost tolls after the first fire totalled 3.5 million euros, the loss to the operator due to the doubled tunnel closure time after the second fire was about 7 million euros. Another example: the German Königshainer Berge road tunnel had to be closed completely in both directions for five months in 2013 for the repair of the inner lining after a fire. The cost of repairs was 2.2 million euros, with an additional 6 million to remedy damage on the approved diversion route.

The situation was different in the Elbe Tunnel near Hamburg, where a maintenance vehicle loaded with propane

cylinders burnt out completely in 2018. Since the tunnel was fitted with fire protection boards, the damaged boards could be replaced; duration of the replacement work: 1.5 days, directly after which the tunnel was opened for traffic again.

“Fires in Tunnels Can Never Be

Completely Ruled Out”

The list of examples can be continued as you will. “Fires in tunnels”, said Prof. Dr.-Ing. Roland Leucker, managing director of STUVA and STUVAtec, at the presentation of the results of the cost-effectiveness and consequential cost investigation, “can never be completely ruled out.” He pointed to the tunnel fire statistics of the ASFINAG (Austrian highway network operator), according to which there are 6.5 vehicle fires (car/truck) for every billion kilometres travelled in tunnels. If heavy goods traffic is considered separately, then the probability that a truck catches fires is higher than that for a car. With a total of a billion kilometres travelled by trucks in tunnels, 25 truck fires occur according to the ASFINAG. These often have fatal consequences, not only regarding damage but also regarding repair and consequential costs.

The danger from fires in tunnels, which can easily reach temperatures of 1000 °C or more, is concrete spalling due to the high temperatures, which can reduce the loadbearing capacity of the construction due to the reduced thickness of the tunnel lining. The strength of the concrete, and especially of the reinforcing steel, already reduces at temperatures of 300 °C.

Fire Protection Boards:

Properties and Function

The mounting of special fire protection boards is one way of protecting the entire construction from excessive temperatures in case of fire and also to look after the steel reinforcement. Aestuver fire protection boards for example can be mounted subsequently (Aestuver Tx) or directly concreted in as cladding (Aestuver T) in underground transport facilities. The board composition without flammable components hinders the emission of toxic or smoke gases in case of a fire. The cement-bound, glass fibre-reinforced lightweight concrete boards further enable exposing for inspection of the concrete structure of the tunnel without damage and also of structural joints, since they can be removed separately and later refixed.

Remediation of Fire Damage

Fire protection boards offer great advantages regarding the remediation of damage caused by a fire incident. Instead of laborious and cost- intensive repairs to the affected areas, only the damaged boards have to be replaced. Their surface can be easily cleaned of soot and other fire deposits. The works can be carried out while traffic continues. In contrast to working with shotcrete for example, it is not necessary to close the tunnel; one lane of traffic can run past the construction site.

Service Lifetime

Regarding the service life of fire protection boards, the European Technical Approval ETA-17/0170 makes definite statements based on the guideline for fire protection products ETAG 018 respectively EAD documents. The stated testing and evaluation results enable the expectation of a service life of at least 25 years for the fire protection board Aestuver Tx. “However it can be assumed that, as is usual with lightweight concrete, considerably longer service lives are probable”, says Prof. Leucker. For this reason, the service life of 30 years given by the manufacturer seems realistic.

Cost Factors

Despite these advantages, the use of fire protection boards is according to Prof. Leucker often turned down as too expensive and therefore not cost-effective. “For the consideration of cost-effectiveness of fire protection boards, above all the initial and consequential costs –the lifecycle costs – are considered in conventional calculations, not however the stoppage times and costs that could be avoided with fire protection boards.”

Study of Cost-Effectiveness Based on

an Example Tunnel

Calculation Basis

What however does it actually cost to protect a tunnel with fire protection boards? And in particular, can costs be saved? “We have tried to put figures to this”, says Prof. Leucker.

“The objective of our investigation was to determine above all the consequential costs and cost-effectiveness of fire protection boards used in tunnels and take all essential parameters into account in the calculation.”

For the study, the overall costs of an example tunnel in the variants with and without fire protection boards were calculated with foreseeable parameters using a calculation model specially developed by the STUVA. In addition to the initial costs of manufacture and installation and the subsequent costs for operation, maintenance and repair, the costs to the overall economy arising from a temporary closure of a tunnel were also taken into account. “These costs”, emphasises Prof. Leucker, “have a great effect on the overall result but are mostly neglected in the decision-making process whether fire protection boards are installed or not.” Furthermore, it was assumed that at least one fire would occur during the service life of the tunnel, which would cause damage to the structural concrete of a tunnel without fire protection boards.

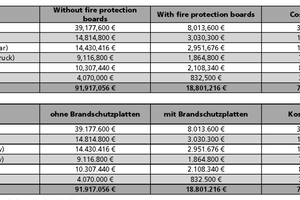

Installation and Maintenance of

Fire Protection Boards

The example tunnel with a perimeter of 16.5 m and a length of 1000 m carries two-way traffic. The area clad with fire protection boards is accordingly 16 500 m². For the determination of lifecycle costs, the calculation model assumes a service life of the fire protection boards of 30 years, taking into account the costs of purchase, disposal and installation of the boards at 142 €/m². The extra cost for maintenance for the main tunnel inspection every six years, during which boards are removed for spot checks in order to inspect the tunnel lining, is set at 1.5 €/m². For the tunnel itself, a service life of 100 years is taken. The calculation also assumes an interest rate of 1.7%. Inflation, on the other hand, is not taken into account so the investigation works on actual figures. Altogether the initial and consequential costs, that is the lifecycle costs, for the tunnel clad with fire protection boards over a lifetime of 100 years is about 5.0 million €.

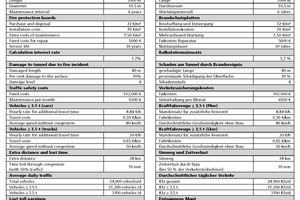

Extent of Damage and Repair Costs

The calculation assumes fire damage to the example tunnel with category 4 damage over a length of 80 m to 70% of the surface of the reinforced concrete inner lining. For the repair of the damaged concrete without fire protection boards, fixed costs in the amount of 70 000 € and costs per unit area of 230 €/m²* are taken. The overall costs are accordingly 282 400 €.

In comparison, for a tunnel with fire protection boards, the fixed costs are 5000 € and the costs per unit area 142 €/m²

(72 €/m² material and 70 €/m² installation) giving overall costs in the amount of 136 200 €. The considerably lower costs are due to the fact that the removal and mounting of the fire protection boards can be carried out with few and simple tools, whereas concrete repair demands much more expensive machinery.

Traffic Safety Costs

Since the example tunnel has traffic running in two directions, it has to be completely closed for the duration of repair works. Therefore 103 000 € fixed costs* have to be taken into account for traffic safety and about 6500 €* for its monthly maintenance. Since a closure time of about 7.3 months* has to be assumed for a tunnel without

fire protection boards, this leads to traffic safety costs of about 150 700 €. For the tunnel with fire protection boards, the closure time is only 1.5 months. The costs for traffic safety are accordingly much less at 112 800 €.

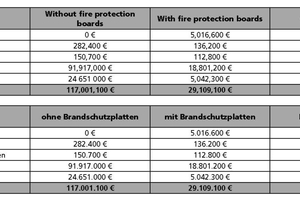

Diversion Costs

The picture for the diversion costs is similar. For the tunnel without fire protection boards, costs of about 91.9 million € arise due to the longer duration of the diversion. In contrast the costs for the tunnel with fire protection boards are 18.8 million € or 73.1 million € less.

Lost Toll Earnings

For the example tunnel, a special toll of 9 € per vehicle is assumed. In order to adequately consider owners of annual cards, 50% of the lost toll is deducted. This gives for the duration of closure of the tunnel without fire protection boards a loss of toll earnings of 24.6 milion €, whereas for the tunnel with fire protection boards the lost amount is only about 5 million €.

Conclusion

The sum of lifecycle costs of fire protection boards, repair, traffic safety and diversion costs as well as the loss of toll earnings for the tunnel variant with fire protection boards is about 29 million €. For the variant without fire protection boards, the costs are about 117 million €. The total costs for the tunnel without fire protection boards is thus about four times as high as the tunnel variant with fire protection boards, with the diversion costs and loss of toll earnings making up most of the extra costs for the tunnel without fire protection boards in comparison with the tunnel with fire protection boards. Just through the difference of the loss of toll earnings (19.6 million €), the considerably higher lifecycle costs of the tunnel with fire protection boards (5 million €) pay off through the quicker reopening of the tunnel. “Even though this result is not applicable without restriction to all tunnels,” emphasises Prof. Leucker, “it can be assumed that the costs of installation of fire protection boards are saved again in the course of the service life if at least one larger fire occurs in this time.” It is indeed not possible to forecast whether a fire will actually occur in a tunnel. “The tunnel fire statistics evaluated for this purpose,” says Prof. Leucker, “do however make this seem likely”.