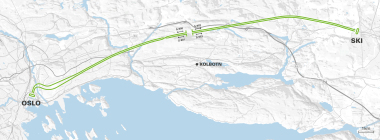

Double Breakthrough on the Follo Line

After about 9 km each through tough gneiss, on September 11, 2018 the tunnel boring machines “Queen Eufemia” and “Queen Ellisiv” achieved a double breakthrough near the city center of Oslo. The Follo Line Project is currently Norway‘s largest infrastructure project and involves the construction of the country‘s longest railway tunnel. The two 20 km long tunnels connect Oslo with Ski further to the south. From 2021 they will shorten travel time for commuters by half.

25 000 viewers witness Breakthroughs

Via live stream, around 25 000 viewers around the world watched the almost simultaneous breakthroughs. Not only for client Bane NOR and the joint venture Acciona-Ghella was it an historic day. The use of a total of four Herrenknecht tunnel boring machines (TBMs) for the major Follo Line Project was a first for the Norwegian tunnel industry too. It is an advance of mechanized tunnelling technology into a country where conventional tunnelling traditionally dominates. But Anne Kathrine Kalager, Project Manager at Bane NOR, is certain: “In future TBMs will be a realistic alternative in large projects, even in our extreme hard rock.” Since late 2016, the TBMs with diameters of 9900 mm each have been boring their way through tough gneiss over a total length of around 36 km. Tunnel boring represents the majority of the long tunnel – 18.5 km of a total of 20 km tunnel on the 22 km long stretch. Completion of the Follo Line Project is planned in December 2021.

Before the final breakthrough of the four machines, four million cubic meters of rock have to make way. In order to master the mission, Double Shield TBMs are used. They are among the most technically sophisticated tunnel boring machines and combine the functional principles of Gripper and Single Shield TBMs. In stable geologies, combining these methods permits the installation of concrete segments parallel to the drive. The best performance of “Queen Ellisiv” under these extreme conditions was 19 rings or about 34 m per day.

High Wear due to extremely abrasive Rock

Factory acceptance of the first TBM took place in March 2016 already, just eleven months after receipt of the order. Only 19 months passed between contract signing and the beginning of work of the fourth and thus last of the machines in Oslo in November 2016. “We were four months ahead of the official schedule with the TBM launch,” explains Fernando Vara, Project Director of the Acciona Ghella JV. During the drive, the tunnelling and service teams work closely together. In Schwanau, up to 40 Herrenknecht refurbishment experts take care of the professional reprocessing of the disc cutters. The linchpin of the drive is the quality of the cutting tools. The disc cutters are made of special steel, 19 inches in diameter and each weighing from 190 kg up to 372 kg. They are pressed against the extremely abrasive rock with up to 32 t of pressure on 70 annular tracks. The geological conditions result in high wear. In the course of the project, approximately 4250 cutter changes are necessary on each machine. “I’ve never had to deal with such hard rock before,” says Francesco Giampietro, longtime TBM manager at Ghella.

Before trains can travel on the Follo Line, two machines must continue their advance through the rock. In the spring of 2019 the final breakthrough of the two other tunnel boring machines is expected, currently still underway in the direction of Ski. Until then, every day “Anna from Kloppa” and “Magda Flatestad” are boring their way through one of the world‘s hardest rock types, with up to 300 MPa.