Adler Tunnel –

Renovation with Fire Protection

The 5.6 km long Adler Tunnel (1995 till 2000) in the Swiss Jura located between Liestal and Muttanz near Basle constitutes part of the Bahn 2000 project. Cracks in the vault over a length of some 40 m near the portal at Muttanz were perceptible only some 10 years after the 2-track Swiss Federal Railways (SBB) tunnel was commissioned. The cause is the swelling gypsum keuper in the surrounding rock, which has raised the tunnel floor by up to 7 cm in the course of time by continuously absorbing water. As a consequence 6 m high and 3.50 m wide concrete bars were installed in this tunnel section as abutments, which were tensioned using anchors and micro-piling to divert the pressure into the rock.

Requirements

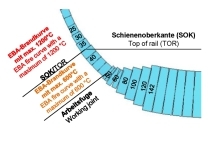

The reinforced concrete bars and the rock anchor heads had to be protected for 60 minutes in accordance with the ISO 834 fire curve in the event of fire so that the tunnel inner shell and abutment zone do not exceed the temperature of 200 °C and the anchor heads 120 °C after this period. In their subsequent operational state the anchor head recesses have to be accessible at all times for monitoring purposes and retensioning the anchors.

A fire protection system was selected for maintaining the clearance profile, which complied with requirements although only 3 cm thick. In addition it had to be capable of withstanding the suction and pressure forces caused by train services in the tunnel, so that a minimal strength of 4 kN/m2 is demanded from the fire protection layer. Trains continued operating on a single track throughout as it was not possible to close the tunnel completely in order to carry out the fire protection measures.

Choice of System

The fire protection mortar Sikacrete-213F was applied on account of the requirements posed on fire protection. This is a hydraulically bonded spraying mortar with Vermiculite used as filler, which affords effective thermal insulation when swollen. This mortar is easy to handle catering for a thin layer thickness and coating; it is tested according to ISO 834 and fulfils the even stricter Dutch dimensioning curve RWS over 2 hours given a layer thickness of only 25 mm.

This fire protection system was also chosen on account of the findings obtained during the extensive fire protection redevelopment of the Wien Mitte Metro station in mid-2009 [4]; 2,200 m² was protected against fire there with Sikacrete-213F given a 25 mm layer thickness in keeping with EN 13501 (REI 180). This fire protection mortar, which is only mixed with water without needing an accelerator, is extremely simple to process.

Executing Construction

First of all the concrete is roughened by high pressure water jet to attain optimal adhesion with the foundation and then wire meshing is placed on the area to be protected. This reinforcement (Bekaert Armanet FP) enhances the service life of the fire protection system – also regarding its resistance to the strain produced by passing trains. Then the fire protection mortar is applied by the wet spraying /thick flow method (screw pump); its surface can be left rough, smoothed or initially coated; in this case the surface was smoothed. Replaceable fire protection plates were installed in the vicinity of the anchor head to facilitate monitoring and retensioning the anchors.

The fire protection mortar was placed section-by-section on account of ongoing train services: first of all in the roof zone and then at the abutments, then the activities were moved to the other track and the other side of the tunnel tackled.

Altogether some 750 m² of Sikacrete-213F was used for the redevelopment scheme. On average 6 kg/m² per 10 mm layer thickness was applied; no accelerator was utilised for this wet sprayed mortar. The fire protection system was applied by Viktor Wyss; the main contractor was the Marti Unternehmung AG and the Basler & Hofmann AG the project compiler for the redevelopment.⇥G.B.