Total Renovation of the Lucerne City Ring

After being operational for almost 40 years there was no denying the effects that traffic and the weather had exerted on the A2 in Lucerne. This key element of the Swiss motorway network is used by more than 90,000 vehicles on average per day. Various engineering structures characterise this section of motorway. In order to ensure that traffic can continue moving during the total renovation in daytime work will be pursued during the main construction phase between 2011 and 2013 at night and on some 25 weekends per year. The traffic zone is available to motorists during the day without restriction. The narrow deadlines, the short net working time during the night and at the weekends as well as the inner-urban conditions call for speedy and quiet working methods. Can these 2 demands be combined?

1 Project Overview

1.1 Constructing in an urban Built-up Area

The City Ring project perimeter consists of the Lehnen Viaduct running along the Reuss in the north, the roughly 600 m long Reussport Tunnel, the Senti bridges with the urban link as well as the 1.5 km long Sonnenberg Tunnel in the south. Over a 4-year total renovation period – the “Lucerne City Ring” project – these elements will all be upgraded to comply with the latest standards. It might all sound so simple but it represents a real challenge in terms of planning, logistics and technique for all those involved in the project. For these operations affect the city of Lucerne with some 80,000 inhabitants and the immediate area with a population of around 200,000 (Fig. 1).

Intervening to such a degree in the A2 possesses far-reaching implications for various interest groups. It is not enough to examine the effects on motorists in the city and the greater Lucerne area. Numerous other considerations as well as interest groups such as residents, commercial enterprises, promoters, tourist organisations etc. must also be represented in the project planning. They all have one thing in common: they want to ensure that their interests are subject to as little interference for as short a time as possible. However these in some cases directly oppose one another and call for contradictory measures. Building quickly with as little noise as possible necessitates a large number of organisational measures, which will be dealt with more extensively as follows.

1.2 Extensive total Renovation

1.2.1 Reussport and Sonnenberg Tunnels

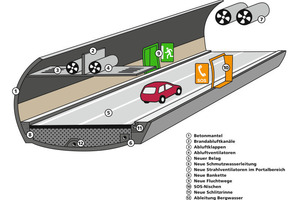

The core element of the main construction phase involves the redevelopment of the Reussport and Sonnenberg tunnels. All kinds of elements are to be repaired or replaced section by section. Fig. 2 displays the most important activities. Apart from structural redevelopment the operational and safety installations (BSA) in the carriageway zone and in the technical control centre will be replaced.

1.2.2 Senti Bridges and Lehnen Viaduct

The bridges reveal typical signs of old age. First and foremost the bridge panels have been serious affected by thawing salt. Leaky carriageway joints have also led to spalling and corrosion at the abutments. The bridge bearings, leaky seals, drainage systems and road surfacing are to be renewed. In addition new noise protection walls, crash barriers and cable duct blocks are all to be installed.

1.3 Sophisticated Construction Programme

1.3.1 Extensive Preparations

Various activities without hampering traffic had to be undertaken in advance. From 2007 till 2010 the Reussport and Sonnenberg tunnels were each fitted with a works conduit (WLT) with a diameter of almost 4 m and several cable ducts. In order to avoid the main activities for structural renovation being hindered by installations and cable systems as much as possible, cables were laid to the BSA installations when ever possible in the WLT. Furthermore the water pipes for Lucerne’s drinking water supply and the extinguishing water for the tunnel are accommodated there. Further preparatory measures entailed the negotiable central strips and the supporting walls relocated to the north of the Reussport Tunnel. At the operational-technical level the existing systems (traffic guidance, superordinated guidance system, video monitoring) were adapted for their special application during the construction phase and measures undertaken in the technical control centres so that the energy supply and communication facilities can be switched over without any interruption at a subsequent point in time. The main operations commenced on November 2, 2010.

1.3.2 Construction Phases

The main operations embrace 5 construction phases. In phases 1 and 2 work in the tunnels towards the north was executed during 2011 (inner and outer wall). The same activities towards the south are foreseen for 2012. By the time construction activities are over in mid-2013, various operational technical tests, training courses, drills by the emergency services and completion work are scheduled. Once they are concluded the motorway operator again takes over responsibility for this section with regard to the operational and technical side of things.

1.4 Costs

The project will cost a total of some 400 million CHF. The structural facilities account for about 2/3rds of this amount. The remaining costs relate to the operational and safety installations as well as various sums accounted for by planners and specialists. The added costs for working at night and during the weekend instead of closing a tunnel bore completely amounts to some 100 million CHF. These added costs were necessary to prevent traffic coming to a standstill on the A2 and the surrounding road network of the city of Lucerne.

1.5 Carefully attuned Traffic Setup

1.5.1 Working at Night and during Weekends

In 2006 the Swiss state and the Canton of Lucerne examined various strategies for ensuring that motorists were unaffected as little as possible by construction sites. The “night closure plus” (night work plus weekend work) traffic concept emerged as the best solution. Putting this traffic concept into practice led to the following basic conditions for controlling traffic:

• Work is largely carried out at night between 8 pm and 6 am (Sonnenberg Tunnel: in each case 1 tunnel bore closed for traffic; Reussport Tunnel: tunnel bore with construction site with an accessible single lane in each case). Traffic was diverted locally through the city of Lucerne. During the day the route section can be used normally (Fig. 2).

• For work that cannot be accomplished in the course of a night (e.g. surfacing the carriageway), 1 bore of the Sonnenberg Tunnel is completely closed for traffic on some 25 weekends per year between 8pm on Friday and 6am on Monday (1 lane of the Reussport Tunnel remains open for traffic). When 1 tunnel bore is closed traffic runs bi-directionally through the second tunnel bore. Work in the closed bore progresses around the clock (Fig. 3).

The described traffic setup was applied in 2011 (work on the northbound carriageway) and 2012 (work on the southbound carriageway, Fig. 3). These weekend closures are geared to months when there is relatively little traffic and cannot be postponed on account of the narrow time frames available. Extensive accompanying measures are applied to make sure that the flow of traffic in and around Lucerne is unaffected.

2 Building as quickly as possible at Night

2.1 Creating clear Requirements

In order to comply with “fast building” the following essential requirements must be properly established during early phases of the project.

The activities construction and operational and safety installations BSA must be geared to one another. The outcome of this coordination work represents a general scheduling programme that applies for all the contractors involved. With more than 60 companies participating, it is essential that the starting deadlines and the times for handing over the individual time frames construction/BSA are established. Milestones are defined, which secure completion of the intermediate targets according to schedule through applying incentive systems. Prior to realigning traffic and at the end of work dependent on the elements time reserves favouring the client must be integrated in the planning, which a priori benefit none of the contractors involved. Nights unaffected by closure and weekends affected by closure have to be established during the submission phase.

Parallel operations by the contractor/construction and BSA must be restricted to a minimum in order to exclude mutual obstruction as far as possible. Prior preparations are essential for extensive total renovation given high time pressure. A utility cable duct detached from the carriageway represents such a central element for these prior preparations. It allows the cables to be installed for the provisional development of the BSA components in the carriageway before construction activities begin and the subsequent removal of the old cable installations in the tunnel verges.

An effective traffic development concept that is geared to the location of the installation yards represents a further important factor of success for nocturnal construction sites on the traffic sector. Traffic lanes leading to the site to secure the logistics have to be planned on the access and exit transport routes

2.2 Interlinking different Optimisations

Once the traffic setup has been established, all processes are then geared to the traffic-free periods it contains. In this connection it is not feasible to work longer to secure deadlines. The daily setting up and dismantling of the site and the ensuing time required for cleaning and inspection reduce the net working time at the Lucerne City Ring to about 7 hours. This short productive time frame presents the contractors with sophisticated logistical tasks. The constricted space conditions and working while traffic is on the move make it practically impossible to increase resources in terms of staff and inventory in order to enhance performance. Thus innovative solutions are needed both for executing construction (as well as for the operational and safety installations BSA), which have to be planned and put into practice by specialised staff. The following list indicates that the optimisation potential has always to be sought both with regard to the project as well as execution.

2.2.1 Speeded-up Adjustments to the Project

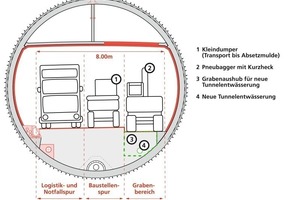

Within the scope of the renovation activities the drainage system in the tunnels will be converted from a mixed system to a separate one. This calls for the installation of new slotted gutter elements including siphon shafts and the replacement of drainage pipes. Such pipes can only be installed during the weekends when the tunnel is closed on account of how they are positioned in the carriageway area. Space conditions in the Sonnenberg Tunnel are severely restricted on account of the narrow driving lanes, the guidance elements and the intermediate ceiling (Fig. 4). As a consequence the contractors are compelled to study the most essential working steps during the preparatory stage in order to secure the on-site logistics and ensure that the emergency and logistics lane is always kept available for emergency services and third-parties.

It is specified that up to 350 m of pipeline has to be replaced per weekend. The work preparations indicated early on that encasing and installation of the pipeline have to be adapted: the concrete setting time of at least 6 hours cannot be adhered to. After testing various alternatives a flexible system (PP pipe wit SN16 ring stiffness class was laid in concrete gravel) was tried out in a field test and subsequently installed instead of encasing it with concrete (Fig. 5).

2.2.2 Increasing Performance thanks to innovative Products

Replacing the intermediate ceiling locally is also subject to enormous time pressure. The intermediate ceiling in the Sonnenberg Tunnel has to be demolished and replaced at 2 points over a length of 22 m. The low clearance height of the intermediate ceiling would only permit an extremely narrow formwork structure after traffic is given the all clear. Within the preparatory run-up the contractor proposed applying a quick-setting concrete and to shutter, concrete and strip the intermediate ceiling during a single weekend when the tunnel was closed. On account of the brief processing time of this concrete (the period during which the concrete is workable) amounting to roughly 3 hours, the police escort the concrete when it is being supplied to the site in the event of a tailback. The application of innovative products and the contractor’s detailed planning have revealed that the intermediate ceiling can be replaced within short time frames without leaving installations standing in the carriageway area.

2.2.3 Application of suitable Equipment

The installation of road surfaces carried out at the weekends when the tunnel is closed is also subject to enormous pressure on account of the large quantities and the short time frames involved. The clearance height and the BSA installations do not permit capacious transport containers to be utilised in the Sonnenberg Tunnel so that the surfacing material would have had to be reloaded outside the tunnel. Lorries equipped with transfer devices were applied to secure transportation right up to the machines for laying the surfacing (Fig. 6). A further example of ensuring fast construction is the choice of suitable equipment for the numerous line construction sites. Excavators with short tails as well as removable arms are mainly applied for uninterrupted passing of working places. The author believes that equipment manufacturers have still a lot to do in evolving hoisting equipment and working platforms.

3 Building as quietly as possible at Night

Night work in inner-urban areas has its price. Noise has to be reckoned with in the adjacent residential districts – for instance in trhe form of air-borne noise caused by demolition work in the tunnel or because the wall concrete has to be removed via high-pressure water jets (HDW) in the portal zones. Proximity to the residential areas, work carried out during the hours of repose for the residents and immissions lasting for months on end call for extensive measures to suppress the noise resulting from construction. These measures are not an obstacle to progress as such as shown in the following.

The foundation is laid by means of a construction noise concept. Towards this end the definition of the time frame for noise-intensive activities is essential. Construction noise must be accorded sufficient importance during the submission stage by e.g. defining noise-suppressing measures put forward by the contractor as an additional criterion or their inclusion in the list of services as an incentive system for adhering to the principles governing noise suppression.

Stationary noise measurements at exposed positions are recommended as a control and guidance instrument. The measurement results are read weekly, analysed and passed on to those involved in the project. The daily charts enable adherence to working times to be checked. At the same time high level values can be analysed in order to resort to targeted additional protective measures. HDW activities (primarily when hand lances are used) cause air-borne noise of up to 80 dBA. The operations at the City Ring have revealed that noise can be reduced by 15 dBA when temporary encasements are applied (Fig. 7).

Structure-borne noise (air-borne noise which passes into buildings via the soil) is more difficult to control. Structure-borne noise occurs to different degrees locally depending on the distance, type of foundation and geological conditions. Stationary measurements of the structure-borne noise cannot be executed comprehensively and are difficult to interpret in dwellings on account of surrounding noises. However structure-borne noise can also be reduced as construction methods are optimised. Thus in some cases trenches located in the vicinity of the old filling concrete were not sprayed but cut using a trench-digging unit (Fig. 8). This method signified that trenches could also be produced outside of the noise-intensive time frames. This in turn had a positive effect on the performance values. Further optimisations were achieved by rescheduling noise-intensive activities from the night to during the day at weekends.

Communication plays an important role both in conjunction with air-borne noise as well as structure-borne noise. Local residents are provided with information relating to what is scheduled. Within the scope of regular get-togethers at which findings are discussed with residents, direct contact between the noise-stressed population and those involved in the project is promoted. Thanks to a project telephone manned 24 hours a day any complaints and needs on the part of the population can be dealt with and responded to at all times. Such calls supply important pointers for adjusting noise suppression schemes, construction measures or spheres of influence.

4 Conclusions

The Lucerne City Ring can scarcely be rivalled in terms of its complexity. The basic conditions relating to traffic, chronology and the environment demand a great deal from all those involved in the project. The capacities and the know-how of the planners, the specialists and the contractors represent the prerequisite for executing such a scheme – as well as the approval of the affected inhabitants of course. However if an attempt is made to come to terms with the large number of challenges in an appropriate manner then it is not impossible to execute speedy and at the same time quiet work in the centre of a city.