Tunnel Solutions for Mexico City

Currently 2 mega-projects are being accomplished in Mexico City – with more than 20 million inhabitants in one of the world’s largest metropolises: the Emisor Oriente Tunnel and the Metro Line 12. The following report is intended to provide an impression relating to just where the problems of this mega-city originate, the people that are involved, how these tasks can be resolved and the fact that tunnels have an important role to play.

It is the year 1325. At the foot of mighty mountains and volcanoes such as the more than 5,000 m high Popocatépeti in the Anáhuc valley in Central America. An eagle soars through the air searching for prey. It discovers a large green snake, which cannot escape its deadly claws and catching it without seeming to interrupt its majestic flight it lands on a large cactus in order to hungrily devour its victim piece by piece.

“The prophesy of the Gods”. The small group of Aztecs also known as Mexica as they call themselves, had succeeded in their mission. “Here”, on a small island in the swamps of Lake Texcoco, “is the place, where we shall build our city, just as the Gods once predicted”. Tenochtitlan – the place of cactus on the rock – was founded and still today the picture of the eagle devouring a snake while sitting on a cactus, adorns Mexico’s national emblem.

The nomads were thus able to find a safe retreat and settle down (Fig. 1). The lake with many small islands provides plenty of fish to feed everybody and fruit, vegetables and flowers flourish on floating gardens – large rafts covered with fertile earth. Causeways set up between the mainland and the islands safeguard the town for they combat flooding if need be. During the next 100 years the network of islands, bridges and canals grows to become one of the largest cities of its time with an area of some 13 km² housing several hundred thousand Aztecs (Fig. 2). Within a short period the omnipotent Aztec empire emerges descending from a few groups of wandering tribesmen.

Let us enter the time tunnel and come out once more in the year 1519 as the Spaniard Cortés lands on what is today the east coast of Mexico with only a few hundred men before razing the fabulous city on Lake Texcoco, where no less than 300,000 Aztecs live, to the ground. They systematically destroy everything that is reminiscent of the Aztecs and establish churches, palaces and houses in Spanish style on the ruins of the former metropolis (Fig. 3). The centre for the Spanish to continue conquering the south of what is today North America and large tracts of Central America was created. The entire lake was drained in the course of time.

Let us enter our tunnel again to jump ahead in time to appraise the airport of Mexico City in 2011 as tunnel’s editor-in-chief quit the gangway to write a report on this fascinating city. He sought no argument, had no destructive intent and was not desirous of establishing any new culture. What he was looking for was an answer: which were the problems facing the world’s 10th largest metropolis with now over 20 million inhabitants and how could these be solved?

But first a few facts about Mexico City. It robs you of your breath even if you are not out jogging. On the one hand on account of the rarefied atmosphere at altitude and on the other because of the omnipresent smog. The traffic never stands still and reports of tailbacks receive short shrift in Mexico City. Mexico City is located in the roughly 100 km wide and 60 km long Mexico valley at a height of some 2,300 m surrounded by mountains on 3 sides. Thus smog is a more or less logical consequence. Given the traffic…

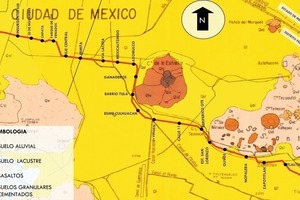

In earlier times the landscape in and around Mexico City was characterised by lakes and swamps. Water flowed in brooks and rivers to the valley from the surrounding hills. There were smallish fresh water lakes in the north and south whereas the deep Texcoco Lake located in the centre was saturated with salt on account of its nitrous bed as well as a lack of drainage and a high evaporation rate. Whereas the Aztecs placed a great deal of emphasis on irrigation and drainage for the lake, the Spaniards initially neglected this terribly and the outcome was serious flooding coupled with accumulations of mud and earth. At the time the Texcoco Lake was situated some 14 m deeper. A canal built behind the foothills at the end of the 18th century to drain the valley, sealing the drinking wells via this drainage system and the removal of unclarified sewage from the valley resulted in the groundwater level sinking constantly. The former lake and the layers of soil located underneath dried out substantially and still continue to do so. This has resulted in pronounced subsidence, currently amounting to around 30 cm per annum. Thus many buildings in Mexico City are subsiding. An exception is provided by the “El Angel” statue with its deep foundations, whose steps have to be extended at regular intervals (Fig. 4). The current system of sewers is as a result partially defective, destroyed and the slope of the land is in the process of reversing. The intrusion of wastewater into leaky drinking water pipelines is no rare occurrence any more.

Additionally the presence of surrounding volcanoes signifies that Mexico City is located in a region endangered by earthquakes and is constantly faced by seismic activity.

All in all Mexico City is facing numerous problems, which must be mastered in future: high air pollution resulting from extreme traffic conditions, an increasingly unsafe drinking water supply, obsolete and leaky sewage systems and inadequate concepts for rubbish disposal.

Two major projects were undertaken in order to overcome at least a part of these problems, which we should now like to present. On the one hand, there is the Emisor Oriente wastewater scheme and on the other the expansion of the Metro system in the shape of Metro Line 12.

Metro Line 12

We spoke to Dr. Ismail Benamar, construction manager of Ingenieros Civiles Associados S.A. de C.V. (ICA) in Mexico City about the Metro Line 12 project. The Metro Line 12 project encompasses design and build involving 3 companies. Two Mexican firms, ICA and CARSO are responsible for construction engineering and the French ALSTROM company is in charge of the electro-technology. Supplying the Metro trains is not included in the contract. All operations on the surface and first and foremost tunnelling by cut-and-cover as well as trenchless methods over the entire length of almost 9 km are included. Excavation is scheduled to be complete in 2012.

At present 11 fully functioning lines constitute Mexico City’s Metro system and according to Benamar it is the world’s fourth largest network with a length of some 200 km and 175 stations (Fig. 5). As far as the route alignment is concerned linking the densely populated suburbs in the south-east with the west of the city is of great significance, for the latter locates the city’s financial district (Fig. 6).

When Metro Line 12 is commissioned in 2012 it is anticipated that around 475,000 passengers alone will use this new line on a daily basis. Altogether between 4 and 5 million people use Mexico City’s Metro every day. In 2010 in excess of 1.4 billion people travelled by the Metro. In this connection 9 to 10 million people actually live in the city central area. The Metro Line 12 is to be equipped with a new electric operating system, totalling 25.4 km the longest on the complete network. Altogether 20 stations are planned for Metro Line 12 (Fig. 7, 8). The frequency will be a train a minute.

The tunnel is altogether some 8.8 km long – with 7.7 km driven by a Robbins EPB machine. Roughly 1.1 km starting from the last station including the parking area for the trains is to be excavated by conventional means. Driving in this final section is made considerably easier by the composition of the subsoil (no groundwater given stable soil conditions).

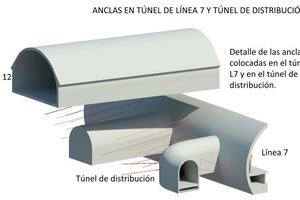

The mechanised drive commenced at the starting shaft in Mexicaltzingo by assembling the TBM and after passing through 7 Metro stations the TBM had to be dismantled in the target shaft in Mixcoac. The excavation’s external diameter amounts to 10.2 m and the final internal diameter is 9.11 m. 40 cm thick reinforced concrete segments with 7+1 elements per ring were used for the lining (Fig. 9). Each segmental ring is 1.5 m long. They were connected by tongue and groove with bolts. The segments were produced by ICA on its own yard in a segment plant located some 30 km away with formwork supplied by Herrenknecht Formwork Technology. Production took place without interruption on a 24 h basis given tricky logistics as segments could only be stored for 1.5 days on a very constricted space at the individual shafts.

The tunnel was driven with a very shallow overburden with a maximum of 8 to 12 m. Most of the time the overburden amounted to 1.5 times the tunnel diameter in extremely tricky subsoil. At the same time very difficult zones were negotiated along the route alignment: a number of large clarification plants had to be underpassed, the foundations of a motorway bridge penetrated, another Metro line negotiated given only 6 m overburden and numerous supply cables intersected the route alignment (Fig. 10). A motorway underpass was intersected, which undercuts another Metro line. Where Metro Line 12 begins a church dating back to the 16th century had to be passed given only a 12 m gap. All told 5 different zones had to be tackled, each of which required a different tunnel design.

The 7 stations are of varying sizes: a number of them are quite normal Metro stations; others on the other hand are transfer stations. They are between 150 and 190 m in length. First they were built and then the TBM moved through them.

Metro Line 12 Tunnelling

To construct the Metro Line 12 first the stations were produced and then the tunnel driven in one direction from station to station. The longest driven section amounts to 1,800 m and the shortest 345 m. The TBM was assembled in 3 sections in the starting shaft and began moving towards the first station. The station was excavated protected by a diaphragm wall. When the TBM arrives in front of the station, a window is set in the wall so that the TBM can pass through safely (Fig. 11, 12). A rail unit consisting of round reinforced concrete segments is arranged on the station floor, on which the TBM runs until it reaches the other end of the station (Fig. 13). There it breaks through the prepared diaphragm wall and follows the planned route alignment to the next station.

The muck is transported to the surface via a belt conveyor. During roughly the first half of the excavation the muck was so moist that it had to be disposed of by pumping. Subsequently the belt conveyor could be deployed as originally scheduled. Furthermore blocks of rock of up to 800 mm in size were anticipated in the final sections of the drive.

During tunnelling operations settlements amounted to between 2 and 5 cm. In the long term settlements of approx. 6 cm per annum are expected.

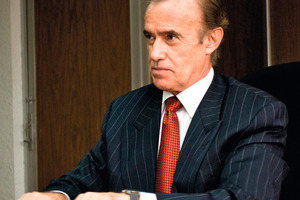

In Mexico City, tunnel had the chance to talk to Enrique Horcasitas Manjarréz (Fig. 14), director of the Metro project (see box p. 26).

What significance does the accomplishment of the project have for Mexico City/the region?

Public transportation in and around the world’s third most populated city will soon get an upgrade more than 15 years in the making.

Work to the Mexico City Metro transit system’s newest addition is on track to finish in April 2012. The $1.41 billion U.S. Metro Line 12 project – also known as the Gold Line – involves the construction of a 25.1 km subway line and 20 rail stations in the southeastern part of the city and surrounding metropolitan area. Planning for the new subway line began in 1996, and construction started in 2008.

This line will be fast, safe and efficient, and will lift the lives of all people in the metropolitan area. This Line 12 will directly transport 437,000 people and improve overall network connectivity for the 4.5 million passengers who use the Metro daily.

After completion, the new Metro line will include a number of features aimed at serving all ridership groups. We are getting together the best technologies to be fully accessible. People with disabilities can use Line 12 without requiring any assistance.

A total of 71 new elevators will be installed in the new stations to assist wheelchair-bound users in getting from street level to platforms.

Visually impaired riders will be assisted through tactical slotted strips installed along the platforms, as well as floors with textures that will change when riders reach the bottom or top of stairs. Signage will be available in Braille and audio messages can be accessed through touching aluminum plates. For the hearing impaired, lights will be installed to indicate when subway doors will close and open.

What would you say is the trickiest part of the project?

At first the new Line 12 of the subway in the stretch Atlalilco-Tláhuac has been the most difficult to build from the stratigraphic point of view of the soil of this area; we have built different structures made of concrete and steel, in addition to the soil mechanics.

Second the availability of human resources, technique and financial execution of the works. The agreement between authorities and citizens to agree in the construction of new massive transportation works. Leveraging the experience gained in the application site of the geotechnical design of the underground structures, unstable soils and seismic zone. The accomplishment of the integral program: to execute the project simultaneously with the construction of the new Line 12.

And at least to fulfill the mandate of the Head of Government: To build and develop the project on time and well-made.

How long does need the project to be finished and when may the first people use the new metro line?

The Line will start working in 2012.

At the end of the day you have to pay the bill: Is it possible to say something about financing the project?

The investment of this project has been the highest and most important of the last 25 years in Mexico City; it‘s the largest investment amount and hardest because it’s complexity.

Contracted Work: 1.4 billion USD

Paid Work: 1,281,572,109 USD

Work to be performed in July 2011: 40,996,482 USD

What made you decide to work with Robbins?

Because the quality of their products, the performance and reliability of their commitments and the value added of their products. Robbins is a global company which always brings us the best maintenance and give us a quick and adequate answer to any problem the machines has. Robbins’ employees are really professional and faithful.

If you could have a look into the future: What would you like to do/to realize?

Continue the development of the Metro Network until it is finished at all, because it is a vital issue for the life quality and competitiveness of this Great City.

Tunnel Emisor Oriente (TEO)

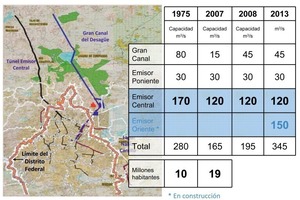

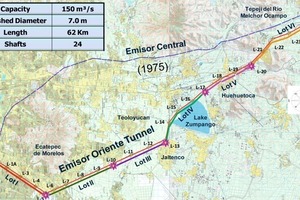

The roughly 62 km long wastewater East (Tunel Emisor Oriente – TEO) will be one of the world’s longest tunnels and will serve to relieve flooding at peak periods (Fig. 15). If heavy rain produces significant precipitation then Mexico City is threatened by flooding if clarification plants and wastewater systems overflow. Mexico City’s sewage system was constructed in the late-1960s. Since then the number of inhabitants has more than doubled. A combination of circumstances – the growing population, the fact that Mexico City is subsiding and the resultant lack of gradient makes the building of one of Mexico’s biggest infrastructural projects essential – the Emisor Oriente. After completion the tunnel’s internal diameter will amount to 7 m. The tunnel provides a capacity of roughly 150 m³/s and will thus greatly relieve the existing wastewater system (Fig. 16). It possesses 24 shafts and an exit portal (Fig. 17). More than 40,000 segmental rings have to be installed and in order to complete the Emisor Oriente according to schedule 6 EPB tunnel boring machines are being deployed. During the drive the overburdens range from 20 to 150 m.

At present the entire rainwater and wastewater from in and around Mexico City are transferred to the open Gran Canal built in 1967 and 1975. However, it is unable to cope with heavy falls of rain to such an extent that the rainwater contaminated with waste breaches the banks. Additionally maintenance work and repairs on this long-in-the-tooth sewage system must also be taken into account so that the discharge capacity is reduced dramatically. It was decided to build the Emisor Oriente Tunnel to gain some breathing space by increasing the capacity by some 150 m³/s.

A Joint Venture consisting of the Mexican contractors ICA, Carso, Cotrisa, Lombardo and Estrella – COMISSA – was commissioned to tackle the Emisor Oriente Tunnel project.

Tunnel was able to glean further knowledge from Raymundo Rincon (Comissa project manger), David Juarez (site manager, ICA), Roberto Gonzales, (general manager Robbins Mexico), Andrei Olivares (project manager Robbins Mexico) and Jeremy Pinkham (Robbins field service manager - The Americas) (Fig. 18).

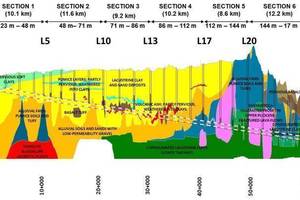

Initially the plan to construct the TEO was too optimistic, numerous changes had to be introduced and various parts of the project could only be undertaken at a later stage so that completion is now envisaged for 2014 rather than 2012. Furthermore the subsoil in sections 4 and 6 for instance is considerably trickier than first expected (Fig. 19). The route alignment had to be partially altered and the shaft concept reappraised as the subsoil conditions substantially held up work on producing the shafts. For example an underground river was discovered. However from the onset 25 shafts were planned for the 62 km route. The shafts possess a diameter of 12 to 20 m and are between 28 and 150 m deep.

The 150 m deepest shaft was produced over the first 100 m with 20 m diameter employing a sealing wall. The final 50 m with 16 m diameter was produced by shotcreting.

The tunnel is being driven with EPB machines from Robbins and Herrenknecht. In July 2011, 2 Herrenknecht machines and 1 Robbins machine were deployed with a further Robbins TBM and a further Herrenknecht TBM being assembled at the end of July and August respectively. A 3rd Robbins machine was assembled in October 2011 so that altogether 6 TBMs are being used for the Emisor Oriente Tunnel.

In November 2009, a Herrenknecht TBM started from Shaft 0 in the 10 km long contract section 1 towards Shaft 5. Flooding caused the drive to be interrupted for more than 6 months. In order to adhere to the tight schedule the Robbins TBM foreseen for Shaft 5 was started in the direction of Shaft 0. Both machines were disassembled at their meeting point, the new Shaft 3a. Contract section 1 is the most important part of the project as it is located in the middle of the city so that it has to be completed as quickly as possible. In the event of floods the water here can flow away and be pumped into the Gran Canal with the aid of a pumping unit.

In August 2010, a Herrenknecht TBM started operating in contract section 2 – also 10 km long – from Shaft 5 in the direction of Shaft 10.

In the 10 km long contract section 3 tricky geological conditions are expected. In 2012 a Robbins TBM began operating from Shaft 10 towards Shaft 13.

In contract section 4 later in 2012, the 10 km long drive with a Robbins TBM began in Shaft 17 heading for Shaft 13. Sandy soil is expected here with volcanic ash and blocks of rock. Water pressure in this section is anticipated at 6 bar.

After the Robbins TBM concludes the additional drive in contract section 1, it will embark on the 10 km long contract section 5 drive from Shaft 20 to Shaft 17.

A Herrenknecht TBM began its 10 km long drive in September 2010 in contract section 6 from the portal to Shaft 20.

Pumps were used initially and now they are using fabric belt continuous conveyors that transfer to J-type vertical belt conveyors to move muck up the shafts. The J-type belt has a small footprint for limited site space, and is used at TEO with a vertical belt storage unit, also to save space in the small site footprint.

Ing. José Miguel Guevarra Torres, Emisor Oriente project manager from Conagua, provided us with an impression of the project (Fig. 20). According to Guevarra the project has to be seen from 2 angles. First of all there is the 62 km long tunnel with 7 m diameter. Then there are a large number of different geologies present at each of the faces for the 6 drives. The excavation runs through 3 different urban districts with a vast number of complicated passages and undercuts in some cases only a slight distance away or with minimal overburden. As the groundwater level falls the city inevitably subsides, a process reflecting extreme differences of intensity at many places depending on the given geological conditions. Work on diverting the surface water from the Mexico Valley and the Mezqual Valley began as far back as 1635. Since then the lake has dried out. The Gran Canal was opened in 1900 to cope with the city’s wastewater and towards this end it had to be diverted via the mountains in the Sierra Guadelupe. Initially this took placed assisted by a defined slope running from the city but in the course of the years this situation has reversed. This is revealed particularly when heavy rain falls and the canal bursts its banks in the shortest possible time. In addition to the Emisor Oriente further clarification systems are under construction. The first important section of the Emisor Oriente is due to be completed in 2012 and then the pumping station with the clarification plant at Shaft 5 can divert floodwater into the Gran Canal. A major problem that still remains unresolved is how to provide Mexico City with drinking water.

Conclusion

Numerous big cities throughout the world have to face up to similar problems. However these may not be as huge and concentrated as they are in Mexico City. Whatever the case solutions that include resorting to tunnels always provide an acceptable, innovative and sustainable way out.