Austrian Tunnel Day 2010

The Austrian National Committee of the International Tunnelling and Underground Space Association (ITA) was the organiser of the Austrian Tunnel Day 2010, for which nearly seven hundred participants, many from abroad, convened in Salzburg. The agenda featured reports on particular challenges encountered in current major projects, experience in tunnel refurbishing, recent developments, and the New Austrian Tunnelling Method (NATM).

The Seventh ITA

Tunnel Day

The Austrian National Committee of the ITA, jointly with its members – the Austrian Society for Geomechanics (ÖGG), the Austrian Tunnel Association (ATA), the Austrian Association for Concrete and Construction Technology (ÖVBB), the Austrian Road and Transport Research Society (FSV) and the Austrian Association of Engineers and Architects (ÖIAV) – organised on October 6, 2010 its Seventh Tunnel Day in the Salzburg Congress Center, with a total of 670 specialists from fifteen countries attending. The Tunnel Day is held here every two years, in conjunction with the Geomechanical Colloquium (October 7-8, 2010).

The proceedings opened with a report on the activities of the ITA and the ITA Austria. These included the issue of the book „NATM – The Austrian Practice of Conventional Tunnelling“, by the ÖGG [2], to all conference participants.

Tunnel Day Prize

for Innovation

This prize (1,500/1,000 euro plus a statuette) for innovations in the field of tunnel construction planning and implementation, a distinction of far-reaching practical significance in tunnel engineering, in view, not least of all, of its beneficial environmental effects, was awarded twice this year, for

• The Lower Inn Valley prestressed arch system, featuring self-supporting steel arches for a 20 cm inner shell for fire-safety, as an innovative reinforcement system, already successfully installed in 9 km of tunnel, with significant economy of resources, and

• Support of TBM operations by means of horizontal directional drilling (HDD), with no hindrance to or obstruction of tunnelling, featuring horizontal bores of around 150 m in length from the reception pit (eight to ten bores, with a deviation of only around 0.25 m at the termination of the bores) and achieving cost-savings of around 50 % compared to grouting injections from the surface.

Exceptional challenges during current large-scale projects

The first half-day focussed on changes occurring during planning and implementation, such as alternative proposals in the context of TBM tunnelling, and a comparison of road tunnel bores constructed at a later stage with those initially driven, and tunnel refurbishing projects.

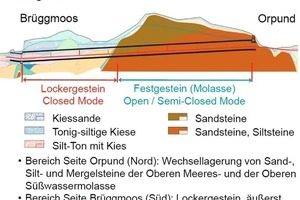

The Biel east link bypass

Dipl.-Ing. Bernd Raderbauer, of Porr Tunnelbau GmbH, Vienna, firstly reported on the „Biel East Link Bypass - Heading of Four Tunnels in Varying Geologies“ [3]. The Biel bypass, part of the A5 autobahn, closes one of the last remaining gaps in Switzerland‘s national highway network, and is subdivided into a west and an east link (Figure 1), each with a length of around 5 km. The east link includes the 1.2 km long Büttenberg Tunnel and the Längholz Tunnel (2.33 km in length), each of them twin-bore tunnels (of 11 m internal diameter) with segmental arch support (30 cm; 6+1) and a concrete interior shell, with a false ceiling for smoke extraction (in the Längholz Tunnel) and a total of eleven transverse galleries; in view of the difficult, variegated geology (Figure 2), both tunnels were headed using an earth-pressure balanced shield machine (S-452, supplied by Herrenknecht AG) with a cutter-head diameter of 12.56 m and a screw conveyor. Other challenges included the manoeuvring of the complete TBM through a surface section (631 m) with no dismantling, and tunnelling under Swiss Federal Railways (SBB) tracks, combined with sophisticated auxiliary provisions, including a slab support structure, various ground improvement measures and application of ground-freezing.

The Visp bypass and the Eyholz Tunnel

The paper presented by Ing. Thomas Längle and Dipl.-Ing. Lukas Käppeli, of Jäger Bau GmbH, Schruns, examined the „A9 Visp Bypass, Eyholz Tunnel - A Road Tunnel in Difficult Geology, with Cross-Sections of up to 300 m²“. Tunnels of a total length of 16.8 km (48 % of the route), including the 4.25 km long Eyholz Tunnel, now under construction using underground tunnelling methods, are needed to close the gap remaining in Autobahn A9, between Brig and Sion; this tunnel will consist of two double-lane bores of 100 to 200 m² excavated cross-section, sixteen transverse galleries (of which five suitable for passage of vehicles; 25 m) and two underground bifurcations (together totalling 730 m in length, with cross-sections of up to 300 m²). Both tunnels are being driven in parallel from east to west; they feature a horseshoe configuration with a false roof and a continuous service duct (10.7 m²) made up of prefabricated concrete elements underneath the carriageway. The internal support consists of non-reinforced concrete of 35 to 40 cm in thickness (reinforced, and 60 to 80 cm in thickness, in the caverns). The extensive geological surveys performed resulted in advance support provisions using single and double jet-grouting screens and face support by means of steel-fibre-reinforced shotcrete and rock bolts in the section through non-cohesive rock, and otherwise with steel-mesh reinforced shotcrete (40 to 50 cm) and rock bolts. The breakthrough in the south bore is scheduled for the autumn of 2011, and completion of the Eyholz Tunnel for 2015. The anticipated construction costs amount to 385 million CHF (275 million euro).

Second bore of the

Bosruck Tunnel

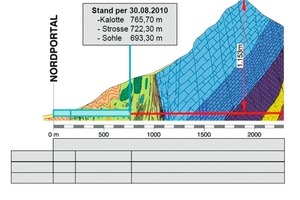

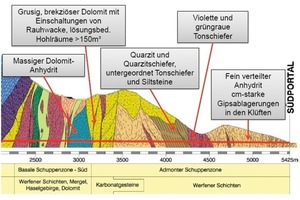

Dr. Franz Pacher, of Alpine BeMo Tunnelling GmbH, Wels, Austria, reported on the „Second Bore of the Bosruck Tunnel - The Challenge of Cyclical Tunnelling in Variegated Geological Formations“ [4,5]. The upgrading of the currently twin-lane Bosruck Tunnel includes the construction of the 5,425 m long twin-lane west bore, featuring five emergency lay-bys (160 m² excavated area), eleven transverse tunnels (of which five suitable for passage of vehicles; 45/50 m²), forty-three emergency telephone stations and forty-eight fire-extinguisher niches, plus modernisation of the existing east bore. Completion of this upgrade of the Bosruck Tunnel, and its subsequent twin-bore (each bore one-way) operation, will eliminate a congestion-inducing bottleneck on the A9 Pyhrn autobahn (E57 Nuremberg to Zagreb). Following the start of work in late 2009, and commissioning of the second bore in 2013, return to full operational status is planned for 2015, after completion of the modernisation work on the existing bore.

The west bore, with an excavated cross-section ranging from 95 to 135m², is being driven from both portals using underground mining methods (see Figures 3 and 4), i.e., tunnelling of the crown followed by bench and floor excavation. The standard cross-section of the tunnel features an open floor or a level or deep invert arch floor, depending on the geological conditions and water influx encountered, and a round cross-section in squeezing rock. The award of prizes and the panel discussion took place during the second half-day.

Tunnel modernisation

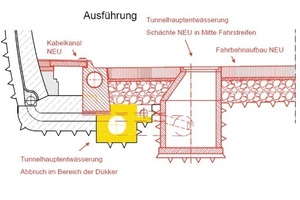

„Tunnel modernisation – a task guaranteed to surprise?“. As Ing. Peter Schwab, of ÖSTU-STETTIN, reported, the 2.5 km long Tanzenberg Tunnel was to feature emergency exits every 500 m and emergency lay-bys every 1,000 m, a drain system for flammable liquids (Figure 5) and fire-resistant structural components, etc. The inadequacy - or total absence - of exploratory surveys resulted in hindrances, project changes and extra work, accompanied by major deviations from the originally specified weights and dimensions. Safety concepts are of importance for execution of such works, since structural modernisation affects the structure‘s load-bearing system; not only the specification of excavation tolerances by the planner, but also a study of older construction methods (a previously recorded film on this topic was shown) and familiarisation with the respective state-of-the-art, are necessary.

There were also noteworthy surprises during the modernisation of the Massenberg Tunnel; the contractually agreed 2,380 m² of excavation in three excavation stages (up to 9 cm) must be set against the 32,834 m², in six stages (up to 18 cm) actually invoiced.

Tolerances in tunnel engineering – small causes with great effects

In future, tunnel modifications will increasingly require the initial removal of the existing inner tunnel lining and the installation of a new one. Together, the upper and lower limiting deviation define the tolerance range, by which the tunnel cross-section must be expanded in order to meet the specified unobstructed tunnel cross-section; the relevant standards (Austrian standard B2203, Parts 1/2 and 2110/2009) require the statement of dimensional tolerances, but not the definition of spheres of responsibility.

As Prof. Dr. Jodl and Dipl.-Ing. Jörg Ehgartner, of the Technical University of Vienna, stated, the existing rules and provisions mean that particular attention must be devoted during the planning and tendering phases to the definition of dimensional tolerances and to the corresponding apportionment of responsibilities between the client and the contractor. In the case of the removal of existing inner linings and accommodation of tolerances, attention must also be additionally directed during the planning phase to the stability of the remaining original lining. Tolerances resulting from a planning variant, such as an excavation method, for example, should be assigned to the contractor‘s sphere of responsibility. Only in this way is it possible to meet the requirements for an unequivocal, complete and impartial description of works and avoid disputes during execution of the works.

Panel discussion

In view of the fact that, in Austria, in particular, the New Austrian Tunnelling method has been in successful use for decades for construction of all types of tunnels, it is now time - after some ten years of the increasing triumph of today‘s modern, highly productive tunnel-boring machines (TBMs) - to pose the question of the future of this tried-and-proven method. This was done in the context of a panel discussion under the motto of: NATM - Quo vadis? The present and the future of the NATM in the construction contract.

Under the chairmanship of Dr. Hans Georg Jodl, of the Technical University of Vienna, five prominent representatives of the tunnel engineering profession were called upon to stimulate audience discussion with short kick-off addresses.

• Dipl.-Ing. Dr. Harald Lauffer, of Porr Tunnelbau GmbH, initiated the proceedings with a retrospective on „The development of the NATM“ from its conceptual origins to understanding of this tunnelling technique“, via its beginnings and the central personalities involved, also examining the essential technical aspects, up to and including formalisation of implementation in Austrian standards (Austrian standards B2203/1983; B2203, Part 1/2001), thus laying the foundation for the following papers.

• Dipl.-Ing. Nejad Ayaydin, of the Ingenieurbüro Geotechnik und Tunnelbau IGT consultancy, reported on the NATM in the construction contract from the planning viewpoint. The current trend toward ever greater legal regulation of civil-engineering and the desire for the „error-free contract“ are, he stated, of little productive benefit and are, indeed, counterproductive for the further development of the NATM. He emphasised, as a particular concern, capability-orientated award of contract to the client‘s consultant engineers on the „best bidder“ model.

• Dipl.-Ing. Johann Herdina, of ÖBB Infrastruktur AG, examined the present status of the NATM in construction contracts from the viewpoint of the experienced major-project client (the reality of tendering, bidding and award). He mentioned constructive behaviour, decision-making competence, concentration on essentials and mutual respect between the project participants as the preconditions for successful project implementation. In his opinion, an NATM „Code of Conduct“ should be drafted on this basis.

• Dipl.-Ing. Manfred Sachs, of ÖSTU-STETTIN Hoch- und Tiefbau GmbH, spoke on the NATM in the construction contract from the implementation viewpoint and, specifically, on the „inflation“ of tendering and contract documentation. One of the essential merits of the NATM is its flexibility, and technical competence, decision-making authority and willingness are demanded from those responsible for the achievement of lean and effective site organisation, i.e., a serious and real „Corporate Tunnelling Responsibility“, which will permit active, effective and innovative implementation of the construction contract.

• Dipl.-Ing. Manfred Bauer, of G. Hinteregger & Söhne Baugesellschaft mbH, took a look into the future of the NATM and perceived no danger for its continuous further development - rather, he emphasised, it is the „swamping“ of the construction contract with legal and tactical topics which constitutes a real threat to correct and rational implementation. The future of the NATM must be sought in a fair and clearly defined contractual environment which will permit innovations for further NATM developments and will allow competent civil-engineering partners to achieve practical implementation of demanding construction tasks on the basis of mutually respectful co-operation.

The contributions made to the discussion demonstrated the interest, the need and, above all, the desire to continue developing the tried and proven NATM tunnelling method in the future. A selection of the most significant comments are noted below:

• Innovation is a spin-off of every development

• The starting point is always an appropriate, jointly determined price

• The construction contract needs slimming down, not fattening up

• Measurable criteria for the elimination of sub-bids must be defined

• Development of an objective and legally watertight best-bidder model.

More details of the Seventh Austrian Tunnel Day can be found in issue 5/2010 of Geomechanics and Tunnelling, or at www.ita-aites.at. The next Austrian Tunnel Day is to be held, again in Salzburg, on December 10, 2012.⇥G.B.