Conveyors at the Lower Northwest Interceptor Project

While continuous conveyors have become the muck removal system of choice in long, hard rock TBM tunnels, they have gained acceptance in soft ground tunnels only recently. Several successful projects in Sacramento, California/USA have proven them to be a favorable alternative to muck cars, producing record rates with high system availability.

The absence of muck cars allows for continual operation behind TBMs, factoring into recent weekly EPB advances as high as 210 m.

“The Robbins-supplied tunnel conveyor system performed remarkably well throughout the drive. The availability of the TBM and associated sub-components was in turn very high for a tunnel heading operating 24 hours a day, 5 days per week,” said Jeremy Theys, Project Manager for the Traylor/Shea JV (contractor for Sacramento’s Upper Northwest Interceptor (UNWI) sewer project).

The design of such systems must, however, take into account the differences in material between soft ground and hard rock, including belt cleaning features, monitoring systems, and other elements.

Below the River: Conveyors at the Lower Northwest Interceptor Project

Sacramento’s Lower North-west Interceptor (LNWI) Sewer Tunnels were the first soft ground tunnels to utilize Robbins continuous conveyor systems. The project, completed by contractor Affholder, Inc. in 2005, was part of the Sacramento County Regional Sanitation District’s (SRCSD) interceptor expansion project. The program encompasses several other interceptor pipelines and tunnels, and will ultimately extend a total of 320 km to provide service throughout the region.

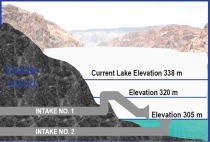

Two 610 m long river crossings were tunneled by a 4.59 m diameter EPB TBM at steep grades through stiff clay, silt and sand. Both tunnels were excavated at a 6 % downgrade to a low point beneath the Sacra-mento River, and then retracted back to the surface from below the riverbed. The alignment made a “v.structure” with a sharp bend in the middle - a difficult proposition for muck removal via muck cars. “We did look at muck cars, but determined they weren’t the best option due to the relatively steep slope of the tunnel alignment. The safety benefits of conveyors on this job were obvious, as there weren’t the potential hazards associated with muck cars travelling on an incline or derailing,” said Steve Norris, Senior Civil Engineer for SRCSD, who worked on the project.

The horizontal conveyor was mounted to the top of the tunnel to allow efficient transport of precast segments to the tunnel heading. The conveyor setup in the launch shaft required that a hole be cut through the sheet piling, so the muck could be directly conveyed to a stock pile area and hauled off site by truck. The sheet piling was extended above tunnel grade to match the height of an adjacent levee for flood protection purposes.

During machine operation, an extensible fabric-belt conveyor was constructed behind the TBM and back-up system. Muck was discharged from the screw conveyor into the loading hopper of the tailpiece, which then elevated the conveyor into the crown of the tunnel. The conveyor system was powered by a 187 kW main drive, which brought the muck out of the tunnel and through the open cut and discharged it into the muck pit. The conveyor was designed for 2 different lengths of 655 m and 663 m lengths, operating at 620 metric tons per hour and running at 180 m per minute.

The continuous conveyor equipment was used on the first crossing, then removed and set up for the second tunnel section as well. It took about 3 days to remove the conveyor and trailing gear out of the initial tunnel and transport it up the launch shaft. The system was easily transported by truck, as the 2 jobsites were less than

25 km apart.

Both sections of tunnel were bored within a 1 year time frame. The TBM used water and foam additives for soil conditioning, which created a toothpaste-like consistency more easily transported by the conveyor.

Record Advances: Conveyance at the Upper Northwest Interceptor Project

A more recent example is that of Sacramento’s Upper Northwest Interceptor (UNWI) Sewer Project, completed in December 2009. The project is unique in several respects – the 5.8 km long tunnel, driven using a 4.25 m diameter EPB TBM, is fairly long for soft ground projects, passes through a number of manholes, and includes a tunnel liner of pre-cast concrete segments with an imbedded PVC layer never before used in North America. The contractor, the Traylor/Shea JV, opted for a continuous conveyor system rather than muck cars, because of the tunnel length and the potential increase in efficiency when compared to muck cars.

The 5.8 km long conveyor system was specially designed for varying ground conditions and water inflows. Design features included sealed transfer points and receiving hoppers. Urethane rubber was used to seal the points and minimize spillage. Additives mixed with the wet ground, such as foam and bentonite, ensured a smooth consistency of muck flow on the conveyor through changing conditions. Cutter-head design aided in injection of the additives, with 4 independent foam injection points to mitigate the risk of clogged lines.

During TBM operation, an extensible fabric-belt conveyor was constructed behind the TBM and over the top of the back-up system in the crown of the tunnel. The muck was discharged from the screw conveyor onto the belt conveyor at the front of the back-up system. From there, the conveyor system was elevated over top of the back-up system and into the crown of the tunnel. As the conveyor traveled through radii down to 400 m, Robbins’ patented self-adjusting curve idlers transferred the load and enabled the system to run through curves. A tripper assembly, located at the open cut in the tunnel, redirected the conveyor up thru the open cut at a 12 degree incline for discharging onto a stacker conveyor. The conveyor system was powered by a

150 kW Main Drive, as well as two 150 kW booster drives added into the system as the machine excavated.

By machine breakthrough, the conveyor had operated at well over 90 % availability for the duration of the drive. The 210 m weekly advance, as well as daily advances of up to 50.3 m achieved on multiple occasions, are believed to be records for a soft ground TBM in the 4 to 5 m diameter range.

Conveyor Design Considerations in Soft Ground

Continuous conveyor systems were first utilized regularly in mining applications, and have since been adopted as one of the primary means of muck removal on hard rock tunneling projects. In recent years, conveyor system design has advanced considerably, from computerized monitoring systems to self-adjusting curve idlers to 20 km long steel cable belt systems. Continuous conveyors for soft ground TBM projects are a fairly recent edition in the tunneling industry, with considerable advantages over muck cars.

“The benefits of soft ground conveyor systems are very similar to those used in hard rock,” said Dean Workman, Vice President, Robbins. “The TBM operates at increased efficiency because they don’t have to stop and wait for muck cars. The necessary ventilation can also be reduced since no locomotives are being used in the tunnel.”

Minimization of Start-Up Time and Maximization of Efficiency

The layout of conveyor systems is designed with swift setup in mind. Unlike many hard rock projects, EPB tunnels are usually relatively shallow and begin from an open cut. The use of a conveyor system setup at the surface can allow for initial use of the system at startup without having to mine a long starter tunnel.

With all components pre-assembled in place at the surface, switching from an initial muck box setup to continuous conveyor often takes a day or less - crews pull the belt onto the system to start mining. By comparison, installation of a rail muck car system can take much longer. Once mining begins, reliability and system availability of a conveyor system are typically higher. Even in tunnels using up to 5 muck trains and multiple California switches, the time required to remove muck from the tunnel cannot compare to conveyor muck removal. In addition, muck cars generally require a much higher level of routine maintenance.

Variable Ground and the Role of Additives

Variable ground is nearly always a part of soft ground tunneling. In the course of a single project conditions can range from weathered rock to sand to clays with changing permeability and ground water. Injection of additives through the cutterhead, such as bentonite, foam, or polymer, can aid in consolidation of muck and eliminate many of the problems associated with conveying fluidized muck. Maintenance of a smooth flow through the cutterhead and screw conveyor onto the belt conveyor system minimizes belt stoppage and material spillage. Additives also have the ability to control the fluidity of very wet ground and help solidify loose, watery material.

Water-bearing Ground and Resulting Design Modifications

If a high amount of water-bearing ground is expected, continuous conveyor systems can be designed to minimize associated risks. Incline is kept relatively low for EPB conveyors – a maximum of about 10 degrees, compared to 18 degrees in hard rock tunnels. In addition, transfer points are entirely enclosed to keep material from spilling out. The enclosed points are equipped with additional belt skirting, a urethane material that seals the edges.

Conveyor Cleaning

Further design modifications minimize the wear of conveyor belt and prevent stoppage due to sticky material. Primary and secondary bore scrapers clean off very heavy material, while a belt wash box installed on the surface near the main drive effectively removes fine material from the conveyor before it cycles through the belt storage cassette. The wash box consists of water spray, which is followed by ‘air knives’ – pressurized jets of air that remove material from the belt without direct contact. The use of air knives eliminates the need for consumable components that come in direct contact with the belt and must be replaced.

Forward Progress

Though many equipment suppliers and contractors only recognize a difference in system availability between conveyors and muck cars over an 1,800 m tunnel length, the advantages are being seen at shorter tunnel lengths as well. Despite variable geology and ground water, the use of additives can effectively consolidate muck flow and prevent spillage on conveyor belts. Further modifications including water tight transfer points have mitigated the risk of muck loss in all but the most water-logged conditions. Though geology on many projects can be quite variable, ground conditions have little bearing on conveyor operation. Belt wipers and scrapers can deal with wet, sticky material as well as hard rock.

Current EPB Projects are planned or are in operation using belt conveyors as muck removal. 3 nearly 10 km long systems are being supplied behind 8.93 m diameter EPBs for Mexico City’s Emisor Oriente project, while another conveyor system will be used behind a 9.6 m diameter EPB for an extension of the Dominican Republic’s Santo Domingo Metro. Increased safety, combined with reliability and short start-up times, are making soft ground conveyor systems a competitive option that may well replace muck car systems in the coming years.