Silvertown Tunnel: Final Breakthrough

On July 23, 2023, the site crews in London achieved the successful final breakthrough with the Herrenknecht EPB Shield in the Silvertown Tunnel project

On July 23, 2023, the site crews in London achieved the successful final breakthrough with the Herrenknecht EPB Shield in the Silvertown Tunnel project

Credit/Quelle: Herrenknecht

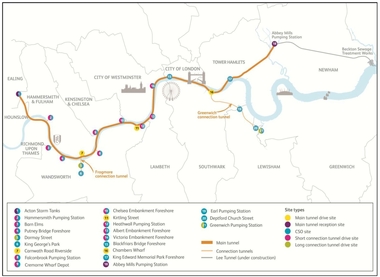

Using the largest tunnel boring machine in the UK, miners from Riverlinx CJV completed driving the second tunnel for London’s Silvertown project ahead of schedule at the end of July 2023. London is building the Silvertown Tunnel in the east of the city, the first newly constructed underground road link between the two banks of the Thames in over 30 years.

To counter chronic congestion in the Blackwall Tunnel, which dates back to Victorian times, London is building the Silvertown Tunnel in the east of the city, the first newly constructed underground road link between the two banks of the Thames in over 30 years. Over a total length of 1.4 km, two lanes run through each side of the tunnel. The diameter of the tunnel boring machine (TBM) of the EPB Shield type (Earth Pressure Balance Shield) designed and supplied by Herrenknecht is correspondingly large. The TBM, christened “Jill” by the miners, is the largest ever used in the UK: the shield diameter is almost 12 m. Including the gantries, the machine weighs 1800 t and is 82 m long. By the time work was completed on July 23, 2023, “Jill” had installed 1120 segmental rings, each weighing around 70 tonnes, to line the tunnel. The contracting joint venture Riverlinx CJV thus completed the tunnelling within less than one year. Breakthrough of the southbound tunnel took place in mid-February 2023.

180 Degree Turn With a 1450 Tonne Machine

After the breakthrough of the first tunnel in February 2023, the 1450 tonne shield machine was rotated together with the cutting wheel by 180 degrees to drive the second tunnel in the opposite direction

After the breakthrough of the first tunnel in February 2023, the 1450 tonne shield machine was rotated together with the cutting wheel by 180 degrees to drive the second tunnel in the opposite direction

Credit/Quelle: Herrenknecht

When building twin-tube tunnels, usually either two TBMs are used or a single TBM is dismantled and returned to the original launch site for the second drive. However, due to the highly complex underlying conditions in terms of construction technology, time and finances, the project managers opted for a different, innovative approach for the Silvertown Tunnel: after completion of the first tunnel, the entire machine was rotated by 180 degrees in order to subsequently bore the northbound tunnel (click here to see a Video of the “U-turn”). To this end, the tunnellers specially excavated an 18 m deep and 40 m long shaft that was open at the top.

In fact, turning such a huge machine required a special procedure developed by Herrenknecht: the shield machine and the cutting wheel are placed on a kind of sled. This in turn slides on cushions filled with compressed nitrogen so that with the help of pneumatic chain hoists the machine can be turned precisely and brought into the new position. The method had already been successfully used in Paris and on the new Stuttgart-Ulm railway line. The 180 degree turn of the 1450 t shield machine in London was accomplished by the Herrenknecht specialists in a single day.

The client of the Silvertown Tunnel project is Transport for London, the institution responsible for road, rail and public transport in the British capital. It awarded the contract for the design, construction, financing and operation of the project to the Riverlinx CJV (Construction Joint Venture) in November 2019. The joint venture comprises Ferrovial Agroman, BAM Nuttall Ltd and SK Engineering & Construction Ltd.