Sandvik DTi jumbos to excavate world’s longest subsea road tunnel

Marti IAV Solbakk DA, part of Marti Group of Switzerland, chose Sandvik DTi jumbos for the excavation of Solbakktunnel, a part of the Ryfast Project in Norway. With its length of 14.3 kilometers, the Solbakktunnel will be the longest subsea road tunnel in the world. Sandvik’s deal with Marti included a purchase of four intelligent computer-controlled Sandvik DTi series jumbos, rock tools and a service contract.

Solbakktunnel is one of the three tunnels in the Norwegian mega-project Ryfast, the purpose of which is to build a ferry-free connection between the local agricultural area of Nord Jæren and Ryfylke. The tunnel will reduce travelling time between the two locations into one third. Traffic intensity is expected to reach approximately 4,000 cars per day at the opening and 8,000 cars per day by 2035.

The 14.3 kilometers of Solbakk-

tunnel consist of two tunnels with two lanes of 70.5 m2. The amount of excavation will be about 1.2 Million m3 and the steepest slope about 7 %, which is the maximum gradient allowed. Another challenge in the project is its depth; the deepest part of the tunnel will be down to 290 m below sea level.

The project owner is the Norwegian Highways Authority Statens Vegvesen. The whole project includes eight contracts, and the E02 for the Northern part of Solbakktunnel was awarded on May 21, 2013 to Marti. The excavation works are scheduled to start on at the beginning of August, 2013. Estimated excavation time is 39 months, with the whole project time being 58 months.

Marti decided to use two DT1131i and two DT921i jumbos for the excavation of the Solbakktunnel because of their superior features and suitable delivery times. All four rigs are equipped with a profiling system from Bever Control, Bever 3D Win Profiler, for scanning of the actual excavated tunnel section. This allows controlling possible under and over break situations and optimizing the process in order to improve the accuracy of excavation. One of the DT921is also has a mechanized rod handling system TRH for long hole injection drilling.

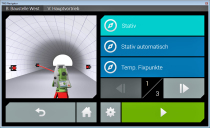

The computer-controlled DTi series tunneling jumbos are available in five models for excavation of 12 to 232 sq.m (129 to 2497 sq. ft.) cross sections, including face drilling, bolt hole drilling, and mechanized long-hole drilling. They feature an advanced iDATA control system, powerful high frequency RD525 rock drills, robust booms, advanced drill string guides, and FOPS-certified, spacious 3i cabins for ultimate usability and excellent working conditions. The DTis are meant for automatic use but allow the operator to fine-tune the process if the rock conditions so require.

Marti Group is a long-term customer for Sandvik. Currently they have, for example, a Sandvik DT920i working at a site in Bhutan, a DT1131-SC in Island and two DT1230is in the Holmestrand railway tunnel in Norway.