“FAIR” Mega Project: Completion of the Structural Work on the North Construction Site

The structural work on the north construction site of the FAIR particle accelerator, one of the largest and most complex construction projects in international cutting-edge research, is coming to an end for the contractor Porr. After six years of work, more than 340 000 m³ of reinforced concrete and 40 000 t of reinforcement steel, a small external staircase was concreted as the last concrete component in February 2025. This marks the completion of an impressive construction process.

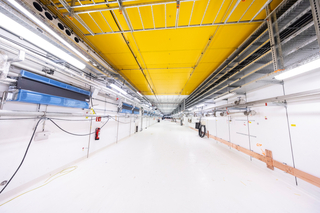

The Centrepiece: The Tunnel for the Ring Accelerator

The FAIR (Facility for Antiproton and Ion Research) particle accelerator is being built at the GSI Helmholtz Centre for Heavy Ion Research in Darmstadt. In the accelerator facility, particles are accelerated to almost the speed of light and made available for fundamental research in physics.

The FAIR (Facility for Antiproton and Ion Research) particle accelerator is being built at the GSI Helmholtz Centre for Heavy Ion Research in Darmstadt. The centrepiece of the entire facility and the northern section is the 1.1 km long, up to 40 m wide tunnel for the SIS100 ring accelerator

The FAIR (Facility for Antiproton and Ion Research) particle accelerator is being built at the GSI Helmholtz Centre for Heavy Ion Research in Darmstadt. The centrepiece of the entire facility and the northern section is the 1.1 km long, up to 40 m wide tunnel for the SIS100 ring accelerator

Credit/Quelle: PORR

The 1.1 km long, up to 40 m wide tunnel for the SIS100 ring accelerator is the central structure of the northern facility area as well as the entire complex. It is supplemented by structurally interconnected underground and above-ground structures such as accelerator and experimental facilities, operating and supply buildings as well as various transfer routes and storage rings.

Porr realised the construction of the circular accelerator tunnel as well as nine above-ground and underground buildings for experiments, operating and supply facilities in the northern construction site. From planning to realisation, the engineering office PDE Integrale Planung, Porr Spezialtiefbau and Porr Ingenieurbau were involved with a total of up to 550 employees.

Complex Project With Various Construction and Planning Requirements

In the accelerator tunnel, particles are accelerated close to the speed of light for fundamental research in physics

In the accelerator tunnel, particles are accelerated close to the speed of light for fundamental research in physics

Credit/Quelle: PORR

Not only the logistics of the large volumes of excavated material were challenging in this project. The large quantity of pipes required for the supply and disposal of the particle accelerator also posed new challenges for pipeline construction. The planning of the pipeline system for the FAIR project followed the principle of ‘form follows beam’ in order to keep the system compact. Only the necessary components were installed in the tunnel, while ventilation pipes and cable protection pipes were laid outside in the sand bed. The high level of complexity resulted from the three-dimensional geometry and the number of pipes that had to be measured, welded and laid. A 3D model served as the basis for the installation. Numerous pipes were laid up to 13 metres high and embedded in compacted layers. For the ventilation, 4400 metres of HDPE coiled pipe and 3000 metres of heat-resistant carbon steel pipes were laid. In addition, 100,000 metres of cable protection pipes were installed. Furthermore, around 2500 empty electrical conduits were connected so that they were protected against pressurised water, while expansion joints enabled vertical displacements.

The three-cell tunnel was built as an open reinforced concrete structure. It is a frame structure with massive concrete components. This includes the 6.35 m thick ceiling with a span of 29 m, which was constructed in a formwork on a supporting structure. The entire structure was built 18 metres below ground and will later be completely covered. A major challenge was the wall axis on which the ceiling rests, with a reinforcement ratio of up to 750 kg of concrete per cubic metre. Porr solved this problem with a self-compacting concrete that was specially developed for this project together with a concrete manufacturer.