EMPA long-term Load Test for Synthetic Reinforcement Fibers

The durability of synthetic fibers in aggressive environments is often questioned. A long-term test undertaken by the Swiss material testing and research institute (EMPA) as part of a KTI project (KTI 10652.1 PFIW-IW) has been able to disprove this assumption for the two-component high-performance fibers from the Swiss manufacturer Brugg Contec.

Test Arrangement

The tests were carried out with two different types of concrete (shotcrete mix and in-situ concrete mix). Different quantities of the Concrix fibers (0.5 % vol. = 4.55 kg/m3 and 1 % vol. = 9 kg/m3) were added to each type of concrete and also for comparison conventional steel fibers with a dosage of 50 kg/m3 concrete. Five square panels (600 x 600 x 100 mm) were made from each mix according to SIA 162/6 (1999) or EN 14488-5 (2006). The flow table consistency, air content and density were determined according to the applicable European standards.

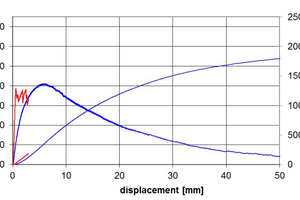

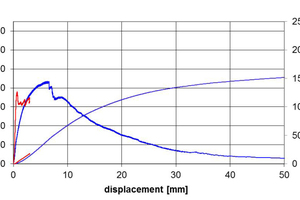

After the specified hardening time of 28 days, the panels were broken, then loaded until a defined crack width and unloaded. Then the various test panels were exposed at regular intervals to various solutions, specifically salt solution, sulphate solution and two percent sulphuric acid, for the duration of one year. Additionally one panel was exposed to outside weather and one further was stored in a climate chamber at 20 oC/90 % RH as reference. After one year, the panels were once again fixed in a test rig and loaded in order to check their residual strength.

Summary of the Results

The panels reinforced with steel fibers showed, as expected, clear signs of corrosion. The result of renewed loading showed correspondingly clearly a reduction of the residual strengths of the fibers. With the Concrix-reinforced panels, on the other hand, the load could even be increased again after reloading, which clearly demonstrates that these synthetic fibers can successfully resist the effect of aggressive solutions.

The currently used square panel test shows the load-bearing capacity of the test panels as a snap-shot in time, after the specified 28 days hardening time of the concrete. The long-term effects of the environmental influences on the reinforcement is not considered.

But precisely this long-term effect is of interest, since structures such as tunnels should have the longest possible lifetime with the lowest possible maintenance costs. Tests at respected institutes with the test arrangement described here clearly show the strengths and weaknesses of the various reinforcement solutions.