Drainage in Tunnel Construction: Münster University of Applied Sciences Award for Nils Schröder

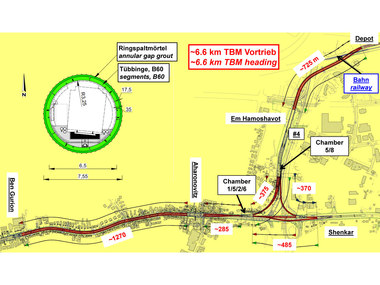

In mechanized tunnel construction, prefabricated segments are used as the tunnel lining. As the tunnel boring machine has a larger diameter than the tunnel lining for construction reasons, an annular gap remains. This annular gap is filled to ensure sufficient stability of the segmental tube. In his master's thesis at the Department of Civil Engineering at Münster University of Applied Sciences, Nils Schröder investigated the practical application of pea gravel as an annular gap material in the mine water drainage tunnel in Ibbenbüren and was awarded a 2024 university award for his work.

The pea gravel is blown into the annular gap between the rock and the tunnel tube through insertion slots from the inside of the tunnel

The pea gravel is blown into the annular gap between the rock and the tunnel tube through insertion slots from the inside of the tunnel

Credit/Quelle: FH Münster/Nils Schröder

“Tunnel construction sites are rather rare, so I was very happy to be able to do an internship at Wayss & Freytag Ingenieurbau AG on the construction site in Ibbenbüren. I realised how interesting tunnel construction is and started looking for a topic for my master’s thesis,” says Schröder.

Nils Schröder (left) investigated the annular gap backfilling with pea gravel at the mine water drainage tunnel in Ibbenbüren in his master's thesis

Nils Schröder (left) investigated the annular gap backfilling with pea gravel at the mine water drainage tunnel in Ibbenbüren in his master's thesis

Credit/Quelle: Herrenknecht AG

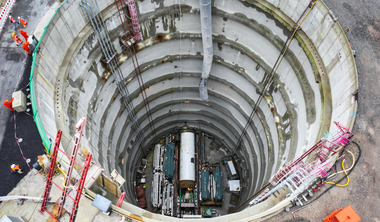

The Tunnel Ibbenbüren consortium (ATI), consisting of Wayss & Freytag Ingenieurbau AG and Ed. Züblin AG, is currently constructing an approximately 7 km long mine water drainage tunnel on behalf of RAG Aktiengesellschaft. It will be used to permanently drain the shut-down Ibbenbüren mine. Pea gravel is being used as a drainage layer to channel the mine water into the tunnel. However, backfilling the annular gap with pea gravel under the existing hydrogeological conditions is untested and there are no comparable projects to date. For this reason, a test structure was set up directly at the construction site before the first application. Nils Schröder used this to investigate different strategies for filling the annular gap.

Filling the Annular Gap With Pea Gravel Against Pressing Water

Entrance to the approximately 7-km-long mine water drainage tunnel

Entrance to the approximately 7-km-long mine water drainage tunnel

Credit/Quelle: FH Münster/Lucie Golde

“The pea gravel is blown into the annular gap from the inside of the tunnel. In some cases, this means working against pressing water,” says the master’s graduate. So we looked at the pressure, the speed and the correct position for blowing. But we also looked closely at the behaviour of the machine in relation to the properties of the pea gravel.

The aim of Schröder’s work is to ensure that the process of filling the annular gap runs smoothly. “This practical task was a lot of fun. Seeing how the solutions developed in the tests are implemented in the tunnel is something very special,” says the university prizewinner. The solutions from the test setup were then further optimised with the help of the skilled workers and their experience during the ongoing construction work.

“Mr. Schröder’s master’s thesis is an outstanding example of application-oriented research. He approached the subject with a great deal of energy and commitment and developed solutions,” says Prof. Dr. Dietmar Mähner of his master’s graduate’s work.

After graduating, Nils Schröder was taken on by Wayss & Freytag and is now a member of the technical office staff at the construction site in Ibbenbüren. “I am looking forward to seeing how the building will evolve until its completion,” says Schröder.