Chesapeake Bay Bridge-Tunnel: Breakthrough at the New Parallel Thimble Shoal Tunnel

The Chesapeake Bay Bridge-Tunnel in Virginia, USA (official name: Lucius J. Kellam Jr. Bridge-Tunnel), has been one of the largest structures of its kind since its opening in 1964. Over a length of 37 km, bridges and tunnels alternate between four man-made islands. Four million vehicles travel through the bridge-tunnel every year. The Thimble Shoal Tunnel, which passes under a shipping canal, was previously a bottleneck for motor traffic: Over a distance of around 2 km, traffic has so far been limited to two lanes, one in each direction. This is set to end in 2028. A major milestone for the expansion has now been reached: at the end of January 2025, the new Parallel Thimble Shoal Tunnel was fully excavated using a Herrenknecht TBM.

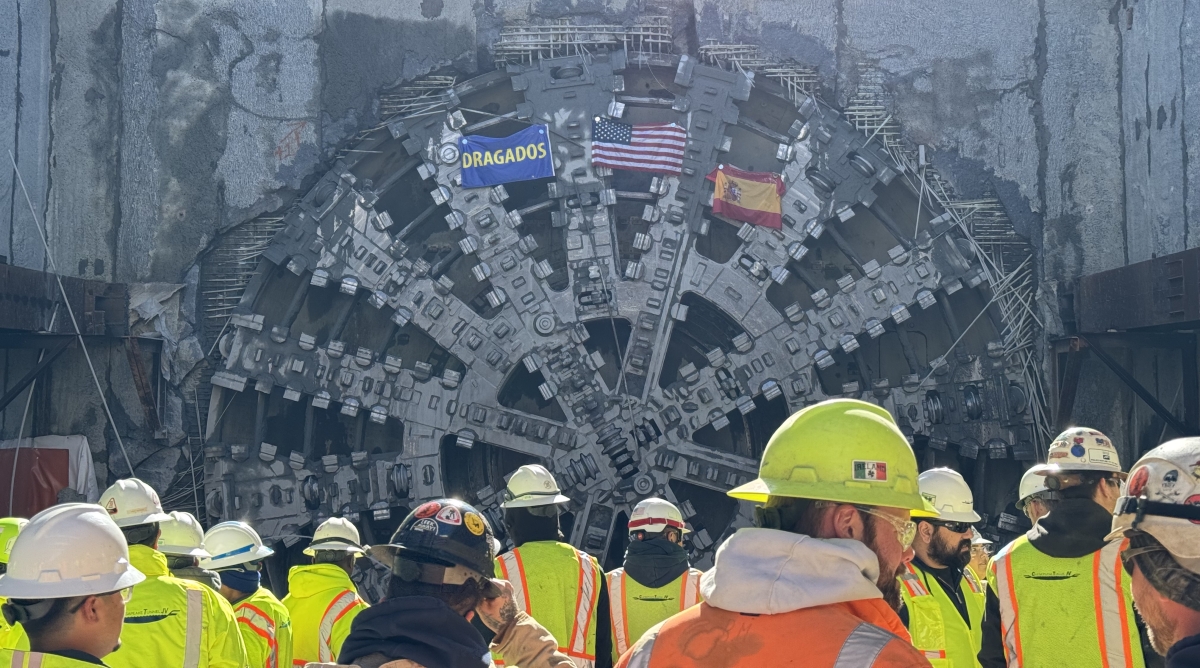

Breakthrough at the Parallel Thimble Shoal Tunnel with TBM “Chessie"

Breakthrough at the Parallel Thimble Shoal Tunnel with TBM “Chessie"

Credit/Quelle: Herrenknecht AG

Chesapeake Bay Bridge-Tunnel The islands: Bridges and tunnels merge in the area of the islands. One of the islands was also the starting point for the Parallel Thimble Shoal Tunnel

Chesapeake Bay Bridge-Tunnel The islands: Bridges and tunnels merge in the area of the islands. One of the islands was also the starting point for the Parallel Thimble Shoal Tunnel

Credit/Quelle: Herrenknecht AG

The joint venture, consisting of Dragados and Schiavone, celebrated the project success together with TBM manufacturer Herrenknecht

The joint venture, consisting of Dragados and Schiavone, celebrated the project success together with TBM manufacturer Herrenknecht

Credit/Quelle: Herrenknecht AG

Following its opening in 1964, it was named one of the “Seven Engineering Wonders of the Modern World.” In 1965 it was awarded the “Outstanding Civil Engineering Achievement”, by the American Society of Civil Engineers. Since 1999, large sections have been widened from two to four lanes: there is a separate bridge with two lanes for each direction of travel. With the new tunnel structure, this extension will now also be realised on the underground route.

TBM “Chessie”

The construction company, a joint venture between Dragados USA and Schiavove Construction Company LLC, relied on a Herrenknecht TBM to build the approximately 2 km long tunnel. An EPB shield with a diameter of 13 210 mm, a drive power of 7000 kW and 46 183 kNm of torque was used. The EPB technology with its earth pressure support is designed for comparatively soft, fine-grained soils and medium earth and water pressures, such as those found when crossing sea floors and rivers at shallow depths. The TBM for the Chesapeake project was given its nickname in a naming competition in the Hampton Roads region: Since then, it has been called “Chessie”.

Specific requirements were placed on Chessie: It had to be designed to be particularly robust, especially with regard to the excavation tools, in order to minimize the need for compressed air entries as far as possible. One challenge at the start and end of the advance was the low overburden in the area of the man-made islands, where large boulders can also be found.

All in all, Chessie was nine months in charge of tunnelling the almost 2 km long route – plus a delay at the beginning, because near the starting shaft in the area of the first island, an old three-meter-high ship's anchor weighing several tons was stuck in the ground, which held up the advance and had to be removed first. But the highly experienced joint venture, supported by the Herrenknecht service team, found a solution, cut and removed the anchor directly in front of the cutting wheel, while the TBM was standing in a special seal block construction.