What makes for fast EPB Advance?

Earth Pressure Balance (EPB) tunneling in mixed ground conditions is a challenging prospect, as it often includes excavation in boulder fields, sections of rock, and sticky clay. A given tunnel may be located in an urban environment with strict settlement limits, under high water pressure or changing water pressure. Maintaining a rapid advance rate in such conditions is a function of many factors from adequate cutting tools to cutterhead design, pre-planning and execution of an appropriate ground conditioning regime. Continued maintenance and proper operation of the tunnel boring machine are equally vital.

The Cost and Benefit of TBM Tunneling

Labor costs for tunnels excavated with TBMs are typically 30 to 50% or more of the total project cost – no small number. Reduction of the time for tunnel construction without increasing staffing therefore results in a substantial savings in total project cost. Finding ways to increase advance rates of machines has a clear cost benefit for all parties involved, and has the added benefit of bringing needed infrastructure online in a more timely fashion. If these reductions in construction time can be applied to even the most challenging projects – mixed ground tunnels with sections of rock, cobbles, and boulders – then they can be applied to more uniform tunnels as well.

In this study, the authors attempt to find commonalities among EPBs operating in mixed ground conditions that achieved higher than average advance rates within a given sample of projects. “Mixed ground” implies that the tunnel alignment contains some fairly easy to excavate material for an EPB, such as soils, sands, gravel and clays in some combination, as well as material that is not easily excavated by an EPB machine including:

Coarse sands and gravels, below the water table, with insufficient fines to form a plug in the screw conveyor

Large boulders requiring disc cutters to break

Competent rock

above the water table

oimpermeable rock below the water table

opermeable rock below the water table

Each of these geological types imposes somewhat unique challenges when excavated with an EPB. These include the fines content – for example, when insufficient fines are present in coarse sands and gravels it is necessary to add foam or polymer to form a plug in the screw.Abrasive ground materials may require addition of abrasion resistant foams and polymers as well. If large boulders are encountered, the design and layout of the cutterhead and cutting tools is particularly paramount. The appropriate EPB cutterhead opening ratio must be maintained, but the openings must also restrict the size of rock pieces that can enter the screw conveyor to avoid a blockage. If a full face of rock is encountered, then the ability for muck to be removed depends on the water table and rock permeability. In impermeable rock, the mixing chamber will fill with rock chips and eventually begin to dump the muck into the screw conveyor under its own weight, making muck removal cyclical. In all cases, abrasion resistant design features and additives are of critical importance to keep equipment in optimal condition and to keep muck flowing more smoothly.

A Study of Projects

A total of 25 projects in 10 different countries were reviewed in the study, employing 40 different EPBs from all manufacturers on mixed ground projects. The projects covered a range of geology and some were decidedly more challenging than others, but all contained at least some sections of geology that included coarse sands and gravels that wouldn’t form a plug, or they contained large boulders or hard rock. Many of the tunnels contained some combination of these “difficult to excavate with an EPB” geologies.

High advance rates were the target data, relative to the other machines in the sample. However, it was not deemed sufficient to have merely had a world record “best day” or “best month”. Instead, projects were looked at over the entire tunnel excavation to find those that were significantly better than others operating in similarly difficult geology. For this purpose, “average weekly meterage” was used as a measure of total productivity, and was collected from various sources. Due to jobsite restrictions it was not always possible for the contractor or consultant to share complete information, and in all cases they wished to not have the names of particular projects published. In addition, the data assumed operation 24 hours per day, 7 days per week, in 12 hour work shifts.

The basic data set for each project/EPB included:

Project name

Country

Length of tunnel

Average weekly advance in meters

Geological description

Water/face pressure

Diameter of the machine

Cutterhead drive type (e.g., hydraulic, VFD electric)

Cutterhead power

Cutting tools fitted to cutterhead and quantity

Muck removal system (e.g., muck cars, conveyor)

Ground conditioning (e.g., existence of pre-project ground conditioning planning and coordination with machine manufacturer and chemical supplier and/or near continuous use of ground conditioning agents, and a list of chemicals employed)

For the 40 EPBMs reviewed the diameter ranged from 5.9 to 10.2 meters, though the vast majority of machines were in the 6 to 6.5 m range. Thirty-one of the machines were employed on metro projects, eight on sewerage projects and one on a train tunnel. They were supplied by three different manufacturers. The face pressure under which they worked ranged from 0 to 13.5 bar with an average of 3.6 bar, with seven projects not reporting the ground pressure. 47 percent of the machines were fitted with variable frequency electric cutterhead drives and the rest were driven hydraulically. The geology on which the machines operated varied widely from sedimentary rock and weathered rock through glacial till, gravel, sands, soils and clays, however all had encountered mixed ground conditions.

54 percent of the projects gave information regarding ground conditioning employed. Several projects gave detailed information regarding ground conditioning, or the information was publicly available in articles published in industry periodicals and conference papers.

30 percent (12 machines) had average weekly advance rates exceeding 100 m/week. 45 percent or 18 projects had average weekly advance rates exceeding the overall average of 85 m/week (see summary table on page 55).

Commonalities of High Performing EPBs

After collecting the data, it was analyzed for what the high performing machines might have in common. Several variables were immediately excluded due to weak correlation, namely machine diameter, cutter configuration, cutterhead drive, face pressure, mucking system, tunnel length, and country.

Some factors had a bit stronger correlation, including contractor experience. All of the contractors operating machines that had average weekly advance rates in excess of 100 m/week had previously excavated at least three prior EPB tunnels with some of them having excavated many. With one exception, the bottom 40% of performers were operated by contractors very new to EPB operations.

High performance appeared lightly linked to a mixed ground EPBM being fitted with a cutterhead designed and fitted for mixed ground (i.e., fitted with disc cutters as well as soft ground tools). In particular, machines that started and had to be stopped one or more times in the tunnel to have the cutting head redressed, from soft ground tools to full disc cutters, under pressure often lost so much time for the retrofit as to make it impossible to achieve a rapid tunnel excavation. Accurate geological mapping must be made available in the tendering stage if the contractor and machine manufacturer are to agree to the correct design and cutting tool selection prior to the start of excavation.

The single factor that had the strongest correlation to machine performance was ground conditioning. Nearly all the best performers had soils tested in a laboratory in advance of the start of boring and had established an initial ground conditioning regime in coordination with the contractor, the machine manufacturer and the chemical supplier. Even those projects that merely brought in the chemical supplier at the start of boring had more success than those who did not employ chemicals or did so only late in the project. There was sufficient evidence to support laboratory testing and coordination between contractor, machine manufacturer and chemical supplier in order to insure the best machine design for chemical injections. This set of circumstances appears to provide the best basis for early high performance of an EPB.

The Importance of Ground Conditioning

The strong correlation shows a good ground conditioning regime can be equally as important as the machine design and logistical aspects on any EPB project. Additives are used to consolidate ground and maintain a smooth flow of muck through the cutterhead, thereby maintaining consistent earth pressure.

Over the decades the use and function of ground conditioning additives has broadened substantially. From providing a method to form a plug in the screw conveyor in coarse materials, ground conditioning additives now provide a method by which to increase the cohesiveness of material, reduce the adhesiveness of material, reduce the friction of material (i.e., reduce the torque on cutterheads and screw conveyors) and more.

In order to establish a baseline for a proper ground conditioning regime on a given project, it is necessary to obtain and analyze an accurate geotechnical baseline report (GBR), and to perform laboratory testing on soil samples.

GBRs for most projects will define the geological and hydrological conditions anticipated along the tunnel alignment including photographs, in situ test results and laboratory test results that identify particle size distributions, presence of boulders, rock types and strengths, ground water information, permeability, moisture content of clays, etc. With the GBR information and international guidelines on ground conditioning, one can form a very rough idea of the program that might be appropriate. Further consultation with the ground conditioning chemical supplier will result in a more well-defined initial ground conditioning plan. It is, however, recommended to take the ground conditioning planning a step further, to the laboratory.

Today there are a growing number of laboratories, in private companies and at universities, which can perform a variety of tests aimed specifically at defining a ground conditioning regime for an EPB project. Typically, these laboratories mix actual soil samples from the job site, at their in situ moisture content, with various foams and polymers and then test the treated samples. One such simple test is a slump test, such as is typically performed on wet concrete to determine its workability. Other tests include permeability testing of the sample to determine the probability of the material forming a plug in the screw conveyor. Still other lab tests include wear testing and even scale model screw conveyance of the material under pressure.

Designing EPBs for Ground Conditioning

A properly designed EPB ground conditioning system requires input from the contractor and the additives supplier. It is imperative that the EPB manufacturer is aware of the ground conditioning plan and that appropriate foam generators, polymer plant, air compressors and bentonite systems are included, as well as proper distribution and injection points on the cutterhead, into the cutting chamber and into the screw conveyor. Results from the 40 EPBs reviewed and anecdotal evidence points to this being an area of coordination which is often overlooked or under emphasized and where a little effort early in the EPB design can result in vastly improved performance on the project.

Many design requirements must be considered and agreed upon by all parties, from logistics and handling of the materials to dosing units and the locations of injection nozzles. In general, it is best to inject all ground conditioning agents from the cutterhead because this provides the best possibility for the agents to flow with and become thoroughly mixed with the excavated material. However, there are times when it might be advantageous to inject conditioning agents into the mixing chamber. For example it is prudent to inject bentonite during a machine stoppage because foam will collapse, eventually leaving an air bubble in the top of the chamber and water in the bottom. Under certain conditions it might be necessary to inject directly into the screw conveyor to form a plug, or to reduce friction and torque at the screw conveyor. When designing the EPB for ground conditioning, it is important that the systems be designed for flexibility and with redundancy. A properly designed EPB will offer the user opportunities to employ all of the conditioning agents (water, foam, polymers and bentonite) in any combination and at an array of injection points on the cutterhead, into the mixing chamber and into the screw conveyor. In addition, because of the danger and difficulty associated with repairs beyond the pressure bulkhead, distribution line redundancy is advisable.

Conclusions

Based on these observations, some high-level guidelines can be developed to offer the highest probability of an EPB reaching the best possible performance in a mixed ground tunnel. Very early in the process, a detailed GBR analysis and laboratory testing are needed to form the basis of a ground conditioning regime. Early in the EPBM procurement/design phase, the contractor, chemical supplier and EPBM supplier should meet and discuss the results of the ground conditioning laboratory results. There should be consensus regarding the systems required on the EPB to properly inject the agreed upon chemicals into the proper locations on the EPB (e.g., cutterhead, pressure bulkhead/mixing chamber, screw conveyor points, etc.).There should be agreement on foam generation plant specifications, additive concentrations, and it should be ensured that those calculations for the sizing of plants (e.g., air compressors) consider the likely face pressures under which the EPB will be working.

The job site should additionally have the ability to do on-site testing of ground conditioning agents in order to make adjustments throughout the tunnel drive without undue downtime for the machine. At the start of boring, on the job site, there should be representatives from the chemical supplier and the EPB supplier to work with the contractor to make any adjustments to the ground conditioning regime to obtain optimal EPB performance. In addition, this time can be used to ensure that the ground conditioning testing that is done on site is done properly, including the training of personnel.

Ground conditioning, as the main factor explored here affecting advance rate, is the first line of influence for the contractor/additive supplier/equipment supplier to influence how material is excavated. The ground conditioning plan, implemented in front of the cutterhead, impacts the entire operation as the material must flow through the machine, out the heading, over the surface and off the site. It affects every part of the job from the number of tool changes required to the amount of cleanup in the heading and on the surface due to spillage. When this global impact of ground conditioning is taken into account, it makes good sense that advance rates are closely correlated. It is this overarching influence that makes a good ground conditioning plan, in combination with a properly designed EPB, one of the most powerful tools available in achieving good project success.

Ground Conditioning in Practice:

San Francisco Central Subway

The Central Subway is part of the San Francisco Municipal Transportation Agency’s (SFMTA) Third Street Light Rail Transit Project. Phase 1 of the 10.9 km, two-phase project began revenue service along the Third Street corridor in April 2007, restoring light rail service to a high transit ridership area of San Francisco for the first time in 50 years.

When Phase 2 is complete, the 2.7 km Central Subway line, excavated at depths ranging from 15 m to 45 m below the city, will extend light rail service through the South of Market and Union Square Districts to Chinatown, as well as provide direct connections to BART and Caltrain, two of the Bay Area’s largest regional commuter rail services. The Central Subway is scheduled to open to the public in 2018. It is estimated that the new subway will serve about 65 000 passengers daily by 2030.

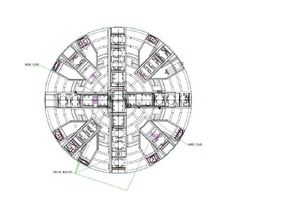

Robbins provided two 6.3 m diameter EPBs to the Barnard/Impregilo/Healy Joint Venture (BIH JV) for the city’s newest rail route. Both machines were designed to enable smooth excavation around tight turns down to 140 m in radius. Mixed face cutterheads were selected and designed to excavate the anticipated wide variety of ground ranging from soft soils to thinly bedded siltstone, shale and sandstone bedrock, as well as concrete diaphragm walls. The wear surfaces of the cutterheads are clad in a combination of chromium carbide plating, hard facing, and tungsten carbide bits to ensure the life of the heads in the abrasive environment. 40 specially designed housings have the ability to mount either disc cutter or soft ground tools.The ample opening ratio is 31 % to allow efficient and controlled muck flow through the heads. Grizzly bars are also incorporated to prevent boulders that are too large to pass through the screw conveyor from entering the mixing chamber. The cutterheads feature five foam and two water injection ports for soil conditioning as well as programmable copy cutters to create additional overcut in order to negotiate tight turns.

Tunnel Excavation

Once the TBMs were launched, preparations began for a complex crossing below live rail tracks. The lowest elevation of the Central Subway profile is controlled by the assumed vertical clearance to the 19.8 m deep invert of the lower pair of live rail tunnels. Constructed between 1967 and 1970 as part of the Bay Area Rapid Transit (BART) project, the four 5.3 m diameter steel-plate lined tunnels are used by BART and SFMTA’s Municipal Metro subway systems and together serve as the main underground transit backbone for San Francisco.

The Central Subway tunnels are being constructed perpendicular beneath the existing BART tunnels. Designer PB/Telamon JV performed extensive numerical and 3D modeling to estimate the ground and structural behavior of the BART crossing. Results indicated that properly operated EPB machines could effectively excavate the crossing without disturbing the rail lines. As an added measure of protection against settlements the design included a radial array of compensation grout pipes placed between the Central Subway and BART tunnels from an adjacent shaft.

The hope was to cross under the BART tunnels at night during a low usage time, preferably on a weekend or after 9 PM on a Friday. But, as with so many things in construction, the first TBM driving the southbound tunnel arrived at a different time than planned – the day before the U.S. holiday of Thanksgiving. This meant the machines had to cross under BART on Black Friday, the busiest shopping day of the year. With careful excavation, minimal settlements were measured, and no compensation grouting was needed.

The second machine excavating the northbound tunnel completed its crossing in February 2014, with equally successful results. The contractor kept a close watch on face pressure, using a mix of foam for conditioning with some bentonite. Backfill and muck volume were closely monitored in a number of ways. Belt scales measured muck weight, which was compared with radar readings of the volume, face pressure and annular grouting volumes. Compensation grout injection was again not needed for the second and final BART crossing.

Since their launch, the EPBs at the Central Subway have excavated incredibly well – as much as 27 m in one 12-hour shift. The first TBM has excavated up to 378 m in one month at an average of 18 m per day. The second TBM has fared even better, turning in a best month of 513 m, with a 20.5 m daily average. The second machine is expected to break through in late June or early July.