Fully Hydraulic Crawler Driven Formwork Carriage for Varying Tunnel Cross-Sections

The A26 is one of the most important infrastructure projects to relieve the traffic congestion in the Austrian city of Linz and its surroundings. This also includes the construction of the approximately 300 m long new Danube bridge. A significant proportion of the bridge approaches will be constructed underground to additionally reduce noise and pollution in the city area.

The A26 project features five different tunnel cross-sections. In addition, there are tight radii of 50 m to 750 m in the bends and various gradients. For the construction of the 1600 m long access tunnel, Peri engineers developed a fully hydraulic, track-driven special formwork carriage

The A26 project features five different tunnel cross-sections. In addition, there are tight radii of 50 m to 750 m in the bends and various gradients. For the construction of the 1600 m long access tunnel, Peri engineers developed a fully hydraulic, track-driven special formwork carriage

Credit/Quelle: Peri SE

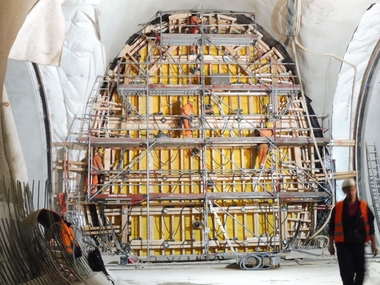

Since May 2020, tunnel construction work has been underway to the north and south of the Danube for the future accesses and exits of the suspension bridge. Five different tunnel cross-sections, the profile transitions, the tight radii between 50 m and 750 m in the bends and the various gradients were just some of the challenges in constructing the 1600 m long access tunnels. Austria's first fully hydraulic crawler driven special tunnel formwork carriage was used for the expansion. This formwork carriage was designed and built by the German company Peri, one of the largest international suppliers of formwork and scaffolding systems.

Customised Special Formwork Carriage

As the very narrow curve radii made it difficult to transport the tunnel formwork carriage. Therefore, an innovative track system was used for the advancement

As the very narrow curve radii made it difficult to transport the tunnel formwork carriage. Therefore, an innovative track system was used for the advancement

Credit/Quelle: Peri SE

For the construction company ICM construction GmbH, solution-oriented and cooperative working methods had top priority during project execution. Thus, Peri engineers developed the first customised and fully hydraulic special formwork carriage with crawler drive for Austria, capable of producing the various cross-sections in a total of 170 concreting sections. The special feature: Since the very tight curve radii made it difficult to transport the formwork carriage, the innovative track drive was used to move it. In addition, the formwork carriage impressed with its remarkable dimensions of 8.07 m height and 14.50 m length as well as 10.70 m width when ready to move and 11.20 m width when ready to pour.

The assembly of the 250-t formwork carriage at the tunnel entrance was carried out under the guidance of a Peri foreman. Within a short time, the first concreting section was successfully completed, so that the formwork could be stripped the very next day and the formwork carriage moved forward to the next section.

Mobile Assembly and Reinforcement Carriages

The waterproofing work was carried out with a mobile assembly carriage. A reinforcement carriage adapted to the block length was used afterwards

The waterproofing work was carried out with a mobile assembly carriage. A reinforcement carriage adapted to the block length was used afterwards

Credit/Quelle: Peri SE

Prior to the operation of the tunnel formwork carriage, a mobile 6 m long assembly carriage with rubber tyres and electric engine was used for the waterproofing work. Afterwards, a reinforcement carriage adapted to the block length of 12 m was applied. The principle of this carriage is similar to the waterproofing carriage. Both consist of a stable Variokit base frame on which a Peri-Up scaffold adapted to the cross-sections was built. This allowed for quick conversion and relocation of the carriages. Furthermore, the mounted scaffold served as a working platform for the site personnel. The scaffold was driven by an integrated hydraulic system.