Thames Tideway Tunnel Project

benefits from digital Strategy

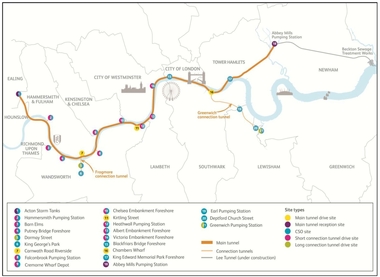

The engineering consultancy Mott MacDonald provided innovative leadership on the UK’s largest-ever water industry infrastructure project, the Thames Tideway Tunnel project, by enabling a going-digital strategy for the CVB JV project team (a joint venture of Costain, Vinci Construction Grands Projets, and Bachy Soletanche). The Thames Tideway Tunnel project’s primary objective is to reduce sewerage overflows into the River Thames, improve London’s water quality, and create new infrastructure that lasts at least 120 years while meeting strict European environmental standards.

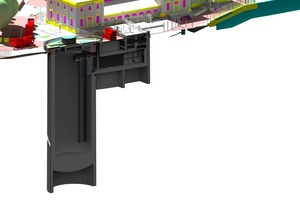

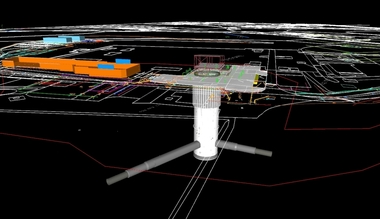

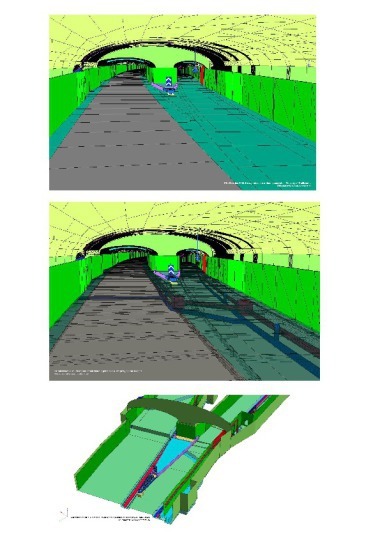

By adopting Bentley Systems’ BIM methodology, Mott MacDonald ensured 3D digital engineering models would provide the immersive environment to support the planning and design phases. Project participants also took advantage of a connected data environment, leveraging an Azure cloud platform for improved collaboration and providing access to the right data at all times.

BIM Strategy coordinates twelve Design Disciplines

Mott MacDonald was the lead designer for the CVB JV responsible for the East contract from Chambers Wharf to Abbey Mills, as well as a connection tunnel from Greenwich to central London. Its responsibility included 10 km of tunnel works located 70 m below the city of London, with six publicly visible shaft sites. Faced with coordinating twelve design disciplines and numerous participating firms spread across Europe, Mott MacDonald had to ensure coordination and collaboration of all stakeholders. Some of the challenges included reducing the number of deliverables on the project (over 50 000), controlling the vast amount of data, standardizing processes, reducing rework, and streamlining the review process.

For this 4 billion British pound project, Mott MacDonald and the CVB joint venture leveraged Bentley applications for design and construction. The adoption of Bentley’s BIM methodology, which included 3D collaborative software, enabled better communication among the project disciplines to make informed decisions. Using ProjectWise, team members could access all deliverable information 80 percent faster than on similar projects. This advantage reduced the total number of deliverables on the project. Using Bentley Navigator, project participants could review models, secure approvals, identify issues, and reduce rework. This helped complete design time six months ahead of schedule.

32 % Savings on developed Design

Among the BIM processes adopted was COBie standards compliance for handover of project data to the owner-operator. BIM models were exchanged using iModels saving 22.5 hours per week. With all data stored in a cloud-enabled connected data environment, and all project participants adhering to the BS 1192 compliance workflow, the team saved 80 percent in project information delivery time and ensured everyone had access to the right data at the right time. Moreover, the 3D models leveraged an automated visualization method to identify potential hazards, ensuring data given to the field was fully compliant to desired safety standards.

By adopting BIM processes and a going-digital strategy, the project team improved collaboration and cooperation with the supply chain and stakeholders. 3D digital engineering models enabled immersive simulation for review and approvals, and provided engineering-ready data required for handover. Mott MacDonald and the CVB JV utilized Bentley applications to ensure a 32-percent savings on developed design.

“The project common data environment, hosted on ProjectWise, allows us to easily access the latest information and has improved and simplified design approvals,” said Michael Gaunt, BIM Manager, Mott MacDonald. ”Bentley ProjectWise provided the tool to coordinate over 80,000 documents totalling 685 gigabytes of data to give 300 users across twelve design disciplines the latest controlled information on which to base design and construction decisions.”