Separating Plant BE-2550 for the

Building of the Eppenberg Tunnel

For more than 25 years, the company MAT Mischanlagentechnik has supplied the latest mixing and separation plants, also for complex and challenging projects. On the large Eppenberg Tunnel project in the Swiss canton Solothurn, the subsidiary of Bauer Maschinen GmbH has now for the first time demonstrated the next stage of their proven separation plant: the BE-2550, which after more than 20 years of experience in the microtunnelling market, represents the entry into the market for large-scale tunnel projects for the medium-sized company from Immenstadt in the Allgäu (Germany).

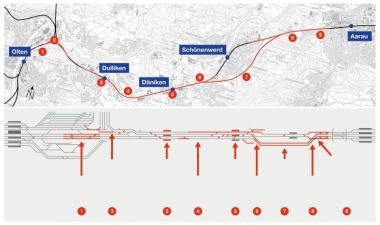

The Eppenberg Tunnel Construction Project

The Eppenberg Tunnel is twin-tracked and about 3.2 km long. It is the key structure of the four-lane widening between Olten and Aarau, one of the most high-volume lines in Switzerland and thus a key project for rail traffic in the central Swiss plain and indeed the whole country. With the new capacity on their main line, Swiss Railways (SBB) plans to run intercity trains on a quarter hourly cycle between Berne and Zürich at peak times, and the preconditions for more regional services will also be provided.

Since November 2016, a tunnel boring machine 115 m long with a weight of 2400 t and a diameter of 12.75 m has been boring into the mountain, until now in open (hard rock) mode although slurry support is being used for the remaining 700 m (soft ground). The new separation plant BE-2550 from MAT Mischanlagentechnik has been in use on this last section of the Eppenberg Tunnel since August 7, 2017 – and is making a decisive contribution to ensuring that the Eppenberg Tunnel can be broken through this winter in Gretzenbach.

Separation Plant moves 2400 m³ of Bentonite Suspension per Hour

The separation plant BE-2550 is composed of six identical individual plants of type BE-425-60 in series, with 2400 m³ of suspension being treated per hour in a closed cycle. The bentonite suspension continuously transports the excavated spoil along a 3 km pipeline to the separation plant, where the excavated spoil is removed from the bentonite in several process stages with screens and hydrocyclone stages and fed back into the circulation to the Hydroshield machine. Two SKC-60-K continuous batching plants provide continuous production of new suspension.

A new Business Field for MAT

For MAT Mischanlagentechnik, the BE-2550 is not only a new model of a new magnitude with its length of 22 m and width of 26 m. The separation plant also represents a new field of business for the company from Immenstadt. That this project could be mastered on time with such complex technical and logistical challenges is a great success, and is the result of the professional collaboration of the entire project team, explain the two project managers for Bauer, Kurt Ostermeier and Kathrin Solbach.

Maintenance of the tight schedule demanded by the customer meant that the most varied companies and departments had to interact. Starting from a precise design, with precise production and a highly qualified team of mechanics and electricians – the BE-2550 was built hand-in-hand in the company workshops. The logistics were also a decisive success factor. All the tools, machine components and site facilities as well as qualified personnel all had to be on site at the right time. Firstly for the works acceptance in Immenstadt, where 25 trucks were loaded in only five working days, and later for the commissioning in Switzerland, where every truck arrived on site almost to the minute.

There are pictures of the MAT plant BE-2550 under //www.youtube.com/BAUERGruppe" target="_blank" >www.youtube.com/BAUERGruppe:www.youtube.com/BAUERGruppe in the area Maschinen/Equipment.