Gloggnitz Tunnel: Material Transport with Komatsu Wheel Loaders

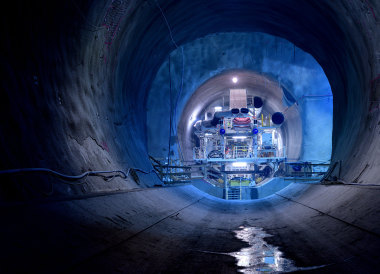

The roughly 27 km long Semmering Base Tunnel is being built between Gloggnitz and Mürzzuschlag in three part-sections as one of the most important major European infrastructure projects. The Austrian tunnel is scheduled to be completed in 2026. The JV Hochtief Infrastructure Austria, Implenia Austria and Thyssen Schachtbau is deploying five Komatsu wheel loaders for loading at the working face and feeding the crusher in the Gloggnitz Tunnel, the eastern construction section, where they are able to prove their efficiency even under constricted conditions. The SBT 1.1 Tunnel Gloggnitz lot embraces the setting up of the two single-track bores with a total length of some 16.1 km. They are built cyclically using the NATM (New Austrian Tunnelling Method) from the Gloggnitz portal and from the Gloggnitz intermediate point of attack via six drives, connected via 16 cross-passages, a service passage and two logistics headings.

Komatsu Wheel Loaders WA 470 and WA 380

DI IWE Ricardo Simon, a mechanical engineer with the JV SBT 1.1 Tunnel Gloggnitz, explains the concrete material flow: “A highlight of this project is undoubtedly that we carry the material to the tip by rail rather than by road. Towards this end, a belt conveyor and. a loading siding were set up on track 1. One of our greatest challenges was to find the proper appliance for transporting material within the tunnel. After extensive scrutiny we decided in favour of a solution with four Komatsu WA 470 wheel loaders loading the material at the working face on to dumpers. They transport it to a loading point in the tunnel, where a Komatsu WA 380 feeds it on to the crusher. From the crusher it is transferred via the conveyor system and track transportation to the tip roughly 108 km away”.

High Demands on Service

Both the WA 470 and the WA 380 impressed with their technical prowess and the appropriate geometry for operating under the extremely constricted conditions. The technical advantages of the machines were rounded off by the tailormade service packet provided by Messrs. Kuhn. Ricardo Simon: “We’re certainly not an easy customer. Messrs. Kuhn went all out to find a solution corresponding with our special needs. Our demands on service are extremely high, for the machines in use must be available 24/7. The support provided by the two Kuhn service centres at Himberg and Kirchdorf/Pernegg fully complies with our requirements. Furthermore, we have the additional safeguard of the extensive Komatsu Care Packet for the first construction phase”. A consignment store was established for the efficient provision of spare parts and it is agreed that a replacement unit will be made available quickly should major damage occur.

The wheel loaders were provided for this tunnelling site with reinforced roof and additional protection for the cylinders. Fire control is also catered for thanks to the semi-automatic fire extinguishing system. In addition to the reversing camera, these wheel loaders are fitted with extra headlights, and ram protection was also reinforced in view of the constricted conditions. According to Ricardo Simon regeneration of the diesel particle filter as required in tunnelling is executed without any problem.

Authorised signatory Herbert Kreiseder, the sales manager with Kuhn Baumaschinen Austria, added: “Machine application here at the Gloggnitz Tunnel represents important proof of performance in tunnelling both for Messrs. Kuhn as well as for Komatsu. We have codeveloped and organised the equipment parts required for this project. At the same time, we saw it as a challenge to comply with the high demands placed on availability of the service staff and spare parts. As the last few months have revealed, the Komatsu wheel loaders operate in a fully satisfactory manner. In addition, the articulated Komatsu Dumper HM 300/5 is also performing very well”.