Full-Area Grouting behind existing Shotcrete Layer

After more than 60 years of use, refurbishment of the road tunnel between Neuhaus and Spitzingsee bei Schliersee, Germany, was urgently necessary. The waterproofing directly behind the shotcrete inner lining was defective and had to be renewed in steps. For this purpose, Sika Deutschland GmbH delivered flexibly settable grouting material.

The tunnel on the way into Spitzingsee runs under a small wood and is used by cars and bicycles as well as pedestrians. In order that the tunnel, which was built in 1953, can remain in safe use in the coming decades, the operational equipment, carriageway paving and tunnel drainage had to be renewed. It was also necessary to repair the tunnel waterproofing since the membrane on the outside no longer fulfilled its function and water dripped continuously from the tunnel ceiling. The consequential damage from the leaks, like spalling and crack formation due to the groundwater freezing in winter, were visible in the existing shotcrete layer.

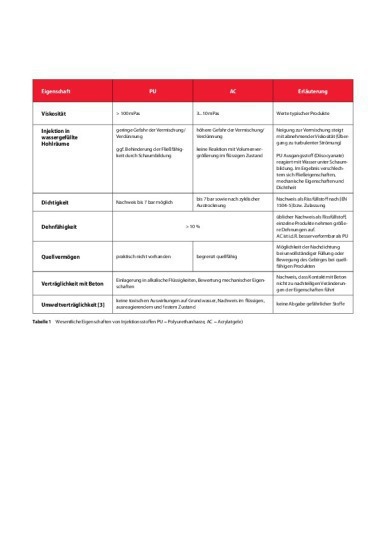

Area Grouting with Acrylate Gel

The cavity behind the inner lining of the 98 m tunnel made the tunnel leak but turned out to be advantageous for the repair work using injection products to seal the tunnel. The acrylate gel could be injected directly behind the shotcrete layer – no deeper drilling into the rock was necessary. The material used for waterproofing was the 3-component polyacrylate gel Sika Injection-311 together with the dispersion component Sika Injection-315 PM. Due to its very flexible settable reaction time, this is particularly suitable for wide-area grouting of any magnitude. The reaction time is always set depending on the cavity size, the packer positioning and the ambient temperature. The cavity to be filled at the Spitzingsee Tunnel was not very large, with a depth of 3 mm. A reaction time of 10 minutes with a drilling pattern of 50 x 50 cm was thus selected. Due to its very low viscosity of less than 10 mPa, the gel grout could be injected very easily through the impact packers in the tunnel sides and thorough drilled threaded packers into the crown. It enabled complete sealing down to the finest cracks. The advantage of the flexible acrylate gel is that it can also compensate movement of the building elements in the reacted state.

Durably protected Shotcrete

Even in constant contact with damp, the Injection-311 acrylate gel maintains its structure. At the Spitzingsee Tunnel, however, no permanent but temporary damp had to be expected. In order to reduce the shrinkage effect of the gel on temporary contact with water, its structure had to be stabilised. The processor therefore injected the dispersion component Injection-315PM together with the acrylate.

After the sealing of the tunnel sides up to a height of 3 m, the crown was sealed. „The good flow properties of the material together with the geometry of the building elements made it possible to enlarge the drilling pattern for the screwed packers in the crown to 1 x 1 m “, explains Sebastian Giersig, project manager for Porr Bau GmbH.