Combined Cement-Polyurethane Grouting Operations in Tunnel and Shaft Construction

Cement-based or chemical grouting materials are the foremost choice to seal water-bearing areas in subsoil or rock efficiently. Anti-wash out resistant cement-based grout mixes and water-reactive grouting materials based on polyurethane are the preferred material for pre-excavation grouting. However, adequate equipment and material technology nowadays enable controlled processing of combined cement-polyurethane grout mixes, which withholds the benefits of both materials types.

1 | Free discharge of standard cement suspension (left), free discharge of a combined cement-polyurethane suspension (right)

1 | Free discharge of standard cement suspension (left), free discharge of a combined cement-polyurethane suspension (right)

Credit/Quelle: N. Liebetrau

Introduction

Excavation of water-bearing formations in tunnelling and shaft construction can lead to short- or even long-term water and material ingress, with sometimes significant effects on structures and the environment [1–3]. Grouting works have proven to be efficient for sealing or consolidating the ground [4–6]. Cement-based or chemical grouting materials are injected into the surrounding ground under pressure to close existing water flow paths.

Injection measures carried out in advance are defined as pre-excavation grouting measures. Works within the immediate excavation or the supported area are classified as post grouting works [7]. Pre-excavation grouting measures utilise the advantage of non-flowing groundwater, provided that a minimum distance to the water-bearing zone is maintained. Conditions with significant groundwater pressure, challenge pre-excavation grouting works in terms of the drilling method, since the full or partially groundwater pressure must be relieved through the borehole itself. Post grouting work often involves a complex approach with active drainage measures, sectioning of grouting areas and multiple grouting rounds. The use of anti-washout cement-based grout mixes [8, 9] or water-reactive polyurethane-based grouting materials [10] has proven indispensable for the excavation progress without significantly influencing the groundwater table and without delay. However, the combination of the two entirely different product groups [11] could not be implemented until now. The usage of appropriate machinery and equipment enables the combination of cement-polyurethane grout mixes in tunnelling and shaft construction.

Stabilising Additives for Grouting

The essential prerequisite for successful grouting in groundwater is based on the postulation of stable grout mixes in contact with water and the calibration of an appropriate reaction time to prevent cement grout mixes or chemical grouting agent from dispensing in solution. The control of wash-out effects in a highly permeable ground, facing high flow rates. (e.g. lateral infiltration to the excavation area or other grouting holes) challenges the execution of the work. First experiences in handling stabilised, cement-bound grouting agents were gained with water glass (Joosten method) or bitumen emulsions by the middle of the twentieth century. However, the grouting works were always carried out under high pressure (> 100 bar) with sufficient rock overburden and without consideration of claquages [12]. The processing of chemical grouting materials based on polyurethane (PU) enabled a significant improvement in a sustainable and environmentally friendly application. However, the consideration of PU is mainly restricted to severe events due to comparable high costs [13].

The individual use of fast-reacting PU foams enables the creation of a growing plug in the immediate area. The application range of cement-based grout mixes for grouting works could even be extended with the ongoing development of underwater concrete and the necessary stabilising additives (Anti-Washout Agents “AWA”) [9]. The admixture of corresponding additives for the cement-based grout mix is generally very low (0.5–3 %). Therefore, it requires an additional dosing pump, suitable to pump the additives at this low percentage to integrate the additives and to guarantee homogeneity and continuity of the grout mix. A reduction of the AWA content for improved workability comes at the expense of stability [8]. The addition of AWA to a cement slurry leads to the formation of long polymer chains, which results in a substantial increase in viscosity. As a consequence, the workability of the cement grout mix is limited to a few minutes. For this reason, AWA is only added via a valve at the borehole to reduce the potential risk of blockages in the grout line.

Based on existing considerations and preliminary trials towards the addition of polyurethane, a system allowing for an infinitely variable integration was developed. The specifications for processing the grout mix are a bleeding rate of 0% of the mixture, a processing time between 5 and 45 minutes (depending on the polyurethane

concentration) and standard equipment, except for the controls for the different units.

Reaction Characteristics of Combined Cement-Polyurethane Grout Mixes

Polyurethanes are synthetic materials that have been used in grouting technology since about 1960 [14, 15]. The two-component polyurethane is formed by an exothermic polyaddition reaction of polyol (A-component) and isocyanate (B-component). In the presence of water, carbon dioxide and urea are formed in combination with the isocyanate as a side reaction. As a result, the carbon dioxide is formed directly in the polyurethane structure and causes the polyurethane to expand. The PU withholds considerable high importance for grouting works due to their diversity and expanding material behaviour.

Cement refers to the inorganic binders and consist of cement clinker, blast furnace slag (only in blast furnace cement) and sulphate. When the cement reacts with the mixing water, a water-containing plastic compound (cement paste) is formed. Primary solidification occurs during the hydration phase, creating a basic initial structure and a final hardening [16].

When polyurethane is added to a cement grouting mix, the polyurea dehydrates the water from the cement paste. The reduction of the water and heat generation by the proportion of PU acts as an accelerator and thickener on the cement grout mix. The reaction acceleration causes a shorter hydration phase and leads to a stabilising effect on the combined cement-PU grouting mix at the same time.

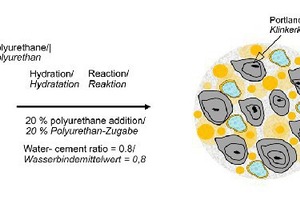

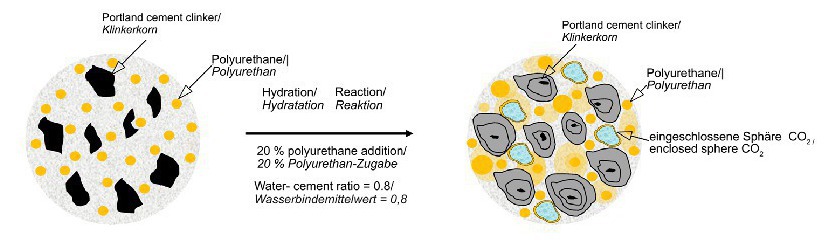

The PU is embedded in the cement grouting mix during the hydration phase and forms an initial structure due to the progressive polyaddition reaction, which stabilises the wash-out effects of the grouting mix. The quality of the combined products is the adequate dispersion and homogenisation of the initial products during the mixing process. Figure 2 schematically shows the emplacement of PU within the cement paste.

2 | Schematic representation of the hydration phase of a combined cement-polyurethane suspension (based on Bayer, 1989)

2 | Schematic representation of the hydration phase of a combined cement-polyurethane suspension (based on Bayer, 1989)

Credit/Quelle: N. Liebetrau

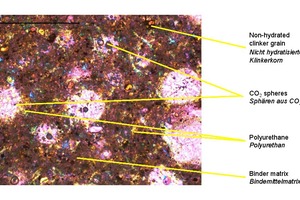

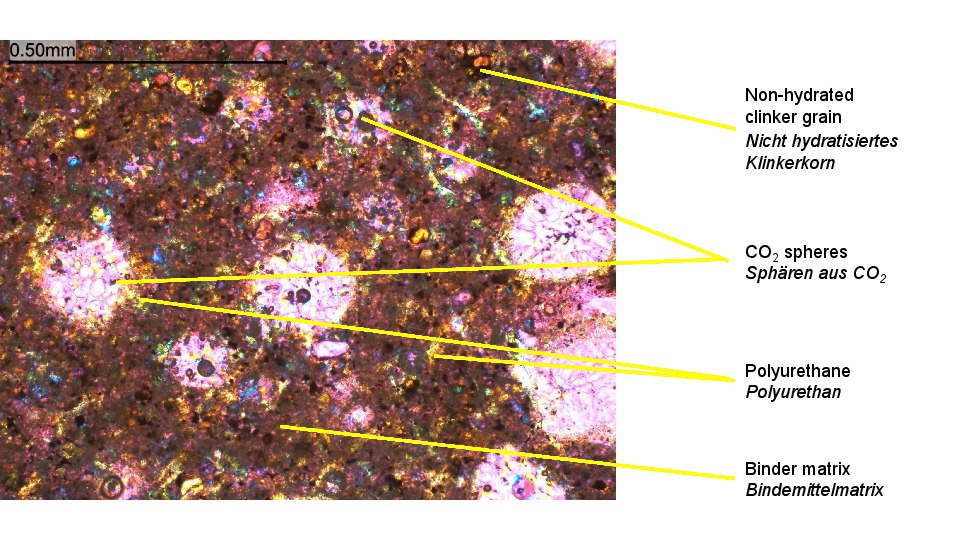

Figure 3 shows a microscopic representation of the spheres of polyurethane, the porous structures formed by the CO2 and clinker grains. The size of the spheres is related to the added amount of polyurethane. As a reaction of the polyurea with water, the chemical gas formation influences the size of the spheres.

3 | Microscopic image (polarisation image) of a combined

3 | Microscopic image (polarisation image) of a combined

cement-polyurethane suspension

Credit/Quelle: Rascor International AG

Properties of a Combined Cement-Polyurethane Grout Mix

Grouting within a high water-bearing zone requires low water–binder (w/b) ratios. Combined polyurethane/cement grout mixes show good applicability concerning mixing with w/b ratios in the range of 0.6 to 0.9 [-]. Following the comparatively highly viscous character of the grout mix, the workability and the resistance to washing out are the crucial factors in determining the properties.

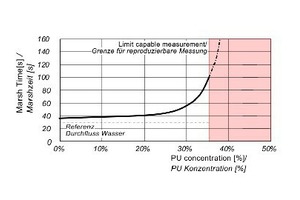

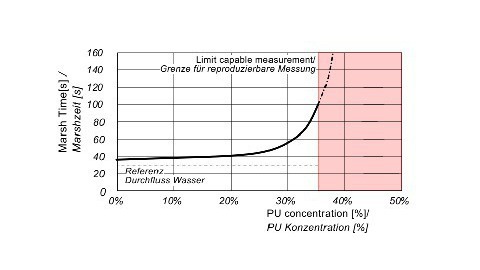

For this purpose, site and laboratory tests were carried out using standard equipment (Marsh funnel, filter press and plate viscometer, according to Lombardi). The tests to determine the rheological and mechanical properties were carried out with a w/b ratio of 0.8. The polyurethane was also with 0, 10, 20, 30 and 40 vol.% (Fig. 4).

4 | Influence of PU concentration on the Marsh funnel time

4 | Influence of PU concentration on the Marsh funnel time

Credit/Quelle: H. Wannenmacher

Determination of Workability – Flowability

The Marsh funnel allows for a rapid determination of the rheological properties of a grout mix[17]. The determination of the Marsh time was carried out utilising a Marsh funnel with an inner diameter of 4.76 mm of the outlet tube[18]. The flow properties of the combined cement-polyurethane grout mix show only a slight increase in Marsh funnel time (approx. 4–5 seconds) up to an initial concentration of approx. 25 %. With increasing PU concentration, however, the Marsh funnel time of a combined cement-polyurethane grout mix increases significantly. Limitations of the machine technology currently allow for a processability of a concentration of approximately 35 %. Anyhow, the risk of blockages in standard grouting lines becomes apparent when the concentration exceeds 30 %.

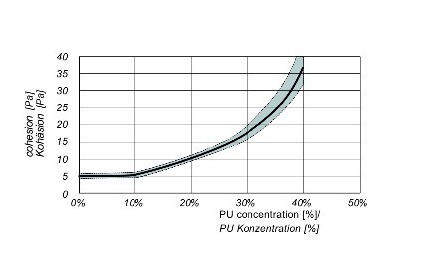

Determining the Stability of the Grout Mix

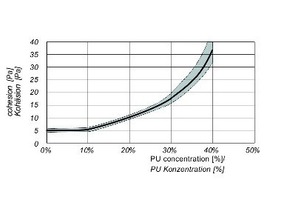

The determination of the grout mix stability concerning wash-out is done by comparing the cohesion and the filtration coefficient. The formulation of the grout mix assumes a high cohesion with a low filtration in interaction with the processability. The cohesion is determined according to Lombardi [19] using a plate cohesimeter. Cohesion increases measurably from an addition of 10% polyurethane. From an addition of > 10%, adhesion to the plate rises significantly. The scattering of the measurements in the upper range of polyurethane addition > 30% is volatile. However, it shows an increased scattering of the cohesion to indicate the partly heterogeneous processing of the high PU content and the associated reaction (see Fig. 5).

5 | Influence of PU concentration on cohesion

5 | Influence of PU concentration on cohesion

Credit/Quelle: H. Wannenmacher

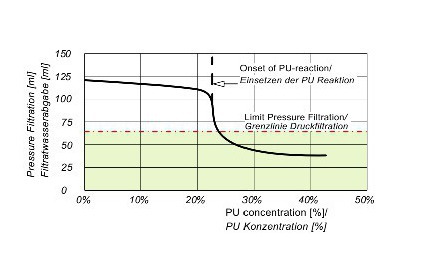

The determination of the filtrate water release provides information about the sedimentation process of the solids in a grout mix and the filtration (squeezing out) of water into the surrounding ground [20, 21]. The tests were carried out immediately after mixing the grout mix according to the specifications of DIN 4126 [18].

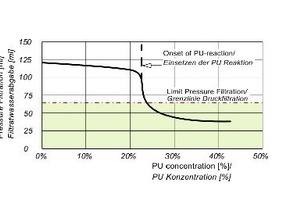

For this purpose, the grout mix is first poured into a standardised cylinder, (400 ml). At the lower end of the cylinder a free filter surface is located, through which the water of the grout mix is pressed out with a filtration pressure of about 7.0 bar in 7.5 minutes. The amount squeezed out corresponds to the filtrate water output in millilitres (see Fig. 6).

6 | Influence of PU concentration on filtrate water discharge

6 | Influence of PU concentration on filtrate water discharge

Credit/Quelle: H. Wannenmacher

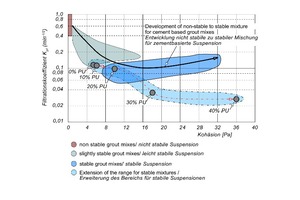

From a concentration of approx. 20% polyurethane, an abrupt influence of the polyurethane on the filtrate water release becomes apparent. The filtrate water release is highly variable throughout the test, with a strongly stagnating character as the test progresses. Therefore, the filtrate water release alone is not yet meaningful for evaluating the resistance of a grout mix to pressure filtration. De Paoli [22] provides the filtration coefficient (pressure filtration coefficient) “KPF” for this purpose. The pressure filtration coefficient is calculated as the product of the quotient of the squeezed volume and the initial sample volume and a constant depending on the test duration (k7.5 min = 0.378).

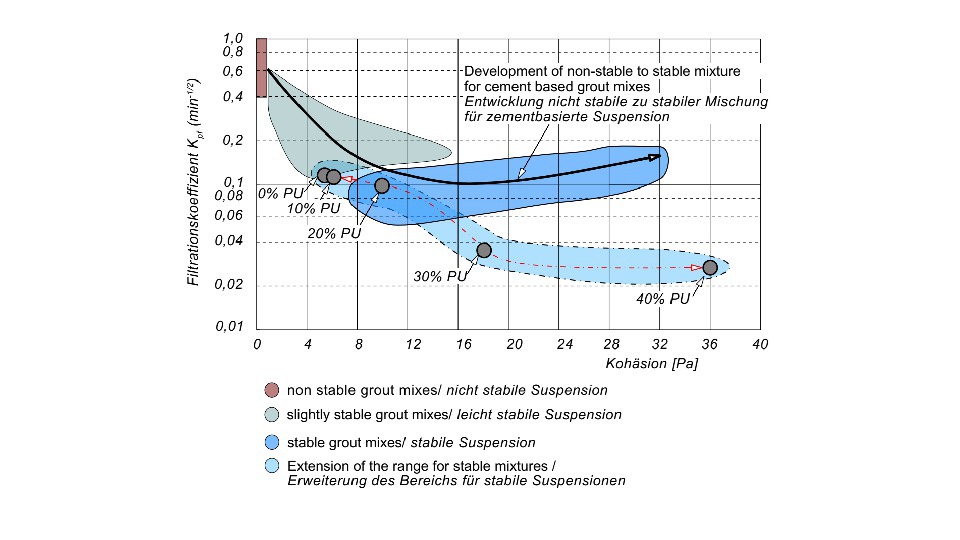

While the grout mix with a low PU content (< 10%) are still in the intermediate range of a slightly stable mixture and a stable mixture, the mixes with a higher polyurethane content are far below the ideal curve of a stable cement grout mixture and thus represent an extension of the range of stable mixes established by de Paoli (see Fig. 7).

7 | Evaluation of the stability of combined cement-polyurethane suspensions (based on de Paoli, 1992)

7 | Evaluation of the stability of combined cement-polyurethane suspensions (based on de Paoli, 1992)

Credit/Quelle: H. Wannenmacher

Mechanical Properties and Strength Development

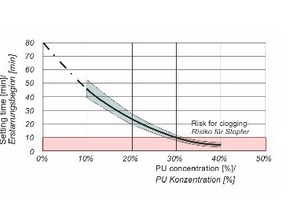

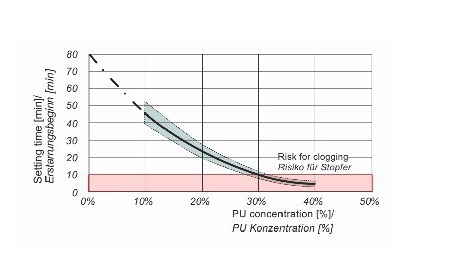

The onset of setting defines a limit value for the workability of a grout mix as soon as it is not moved. According to Kainrath [23], the onset of the setting of the cement grout mix was determined when the shear stress of 100 Pa was reached for the cement grout mix. However, the addition of PU to the cement grout mix changes the inherent setting behaviour of the grout mix. It poses a risk of damaging the test equipment so that the values were determined with a simple tilt test. Solidification begins as soon as the material in a container can be tilted by 90° without material loss. The onset of solidification is highly dependent on the PU concentration and falls to less than 10 minutes when 40 % PU is added to the grout mix (see Fig. 8). Since the onset of solidification in this range is also highly volatile, a grout mix of 30% or more can undoubtedly lead to a reaction and blockage of the lines.

8 | Influence of the PU concentration on the onset of the solidification process

8 | Influence of the PU concentration on the onset of the solidification process

Credit/Quelle: H. Wannenmacher

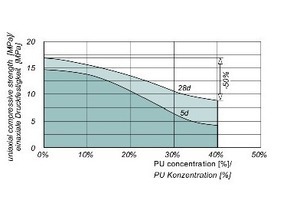

The proportion of polyurethane within the grout mix shows a considerable influence on strength development. The ratio of enclosed spheres of polyurethane and pores of CO2 leads to a significant reduction in strength compared to a pure cement grout mix. For a 40%

polyurethane-cement grout mix, the decrease in strength amounts to approximately 50% (see Fig. 9). The strength reduction is only of secondary importance due to the primary sealing purpose.

9 | Influence of PU concentration on strength development

9 | Influence of PU concentration on strength development

Credit/Quelle: H. Wannenmacher

Grouting System for Processing a Cement-Polyurethane Grout Mix

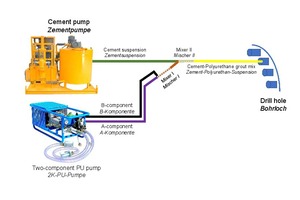

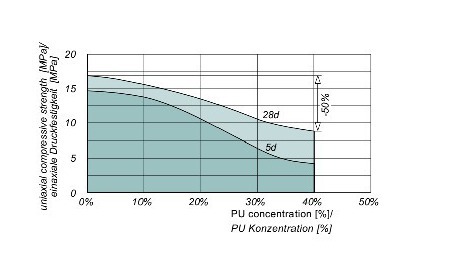

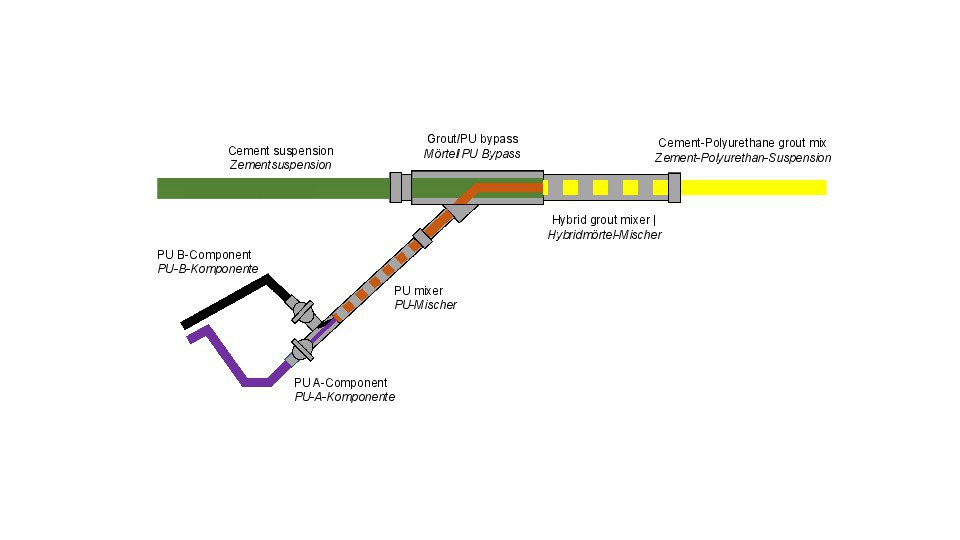

A standardised grouting system can be used to process a cement-polyurethane grout mix, whereby the processability must be tested employing flow tests and free discharge tests. The grouting system consists of a grouting unit for the cement and a separate grouting unit for the polyurethane, including a bypass system, with a control unit, if demanded (see Fig. 10).

10 | Injection unit consisting of cement and polyurethane pump connected by a bypass system

10 | Injection unit consisting of cement and polyurethane pump connected by a bypass system

Credit/Quelle: N. Liebetrau

The grouting unit for processing the cement grout mix consists of the grouting pump, a colloidal mixer and an agitator. In addition, an integrated data acquisition system for measuring the flow rate and pressure at the pumps is required for each flow line. The control unit is connected to a data acquisition system of the individual pumps. For dynamic processing of different PU proportions within a grout, an extension of the control unit is required [24].

A separate polyurethane pump is used for PU processing (here: 2-component polyurethane). The two-component polyurethane (components A and B) is sucked in via two separate suction lines and fed to the bypass (mixer I+II) via two separate pressure hoses. Two pressure gauges at the 2-component polyurethane pump facilitate the control of the acting feeding.

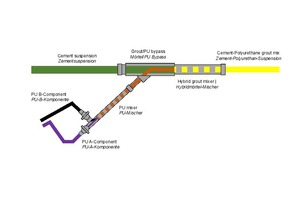

The bypass system consists of two mixing systems and a bypass (see Fig. 11). In Fig. 6, the cement line (green) is marked. The PU is formed by mixing the A-component (violet) of polyol and B-component (black) of isocyanate through a static mixer (mixer I), which is fed downstream through a bypass to the cement line. The final cement-polyurethane grout mix is generated by a second static mixer (mixer II). Finally, a standard hose connects the grout line to the packer, through which the borehole is pressurised.

11 | Mixing of the cement suspension and the polyurethane by means of the bypass system

11 | Mixing of the cement suspension and the polyurethane by means of the bypass system

Credit/Quelle: N. Liebetrau

Attempt to Quantify Cement-Polyurethane Grout Mix on the Grouting Process

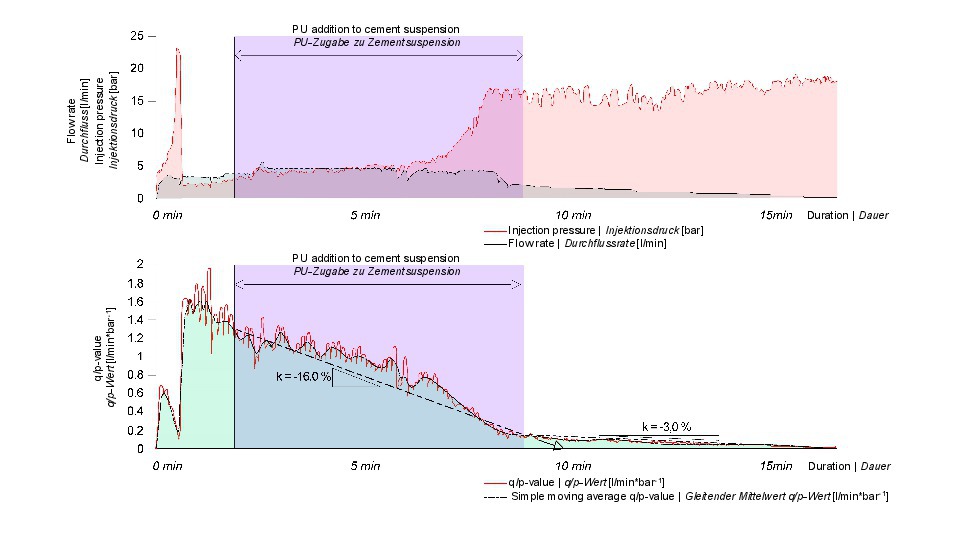

In small-scale tests, the properties of the cement-polyurethane grout mix show improved characteristics about filtration and initial stability. However, conclusions on the improved properties in the implementation can only be drawn by actual grouting works. Lombardi [25] suggests the q/p method for controlling grouting works. The q/p method compares the flow rate q [l/min] with the grouting pressure p [bar] over time. The q/p value is independent of the steering of the grouting work.

The evaluation of q/p values of advance sealing grouts shows a range of values at the beginning of the grout from 1.5 to approx. 3.0 [l/min/bar]. The steady reduction of the q/p value indicates saturation of the defects of a rock mass. Accordingly, the slope of the q/p value can be used to conclude the effectiveness of the grout. According to Lombardi, sufficient saturation of the ground is achieved when the q/p value reaches a level of < 0.2 [l/min/bar].

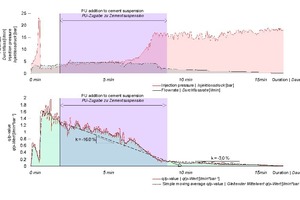

12 | Example 1 – Injection data recording of a cement-polyurethane suspension incl. a graph of the q/p value

12 | Example 1 – Injection data recording of a cement-polyurethane suspension incl. a graph of the q/p value

Credit/Quelle: H. Wannenmacher

Example 1 in Figure 12 shows the process of pre-excavation grouting with a temporal addition of 20 % PU immediately after filling the borehole and reaching the maximum q/p value. the addition of polyurethane introduces a relatively steep gradient of the q/p ratio. Upon reaching a pressure plateau at a reduced flow rate, a stagnation of the q/p curve occurs. The lower gradient as an expression of the minor q/p curve ratio leads to a prolongation of the grouting operation of approximately

7 minutes with a corresponding volume of approx. 7 litres.

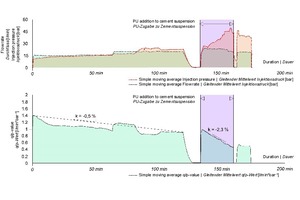

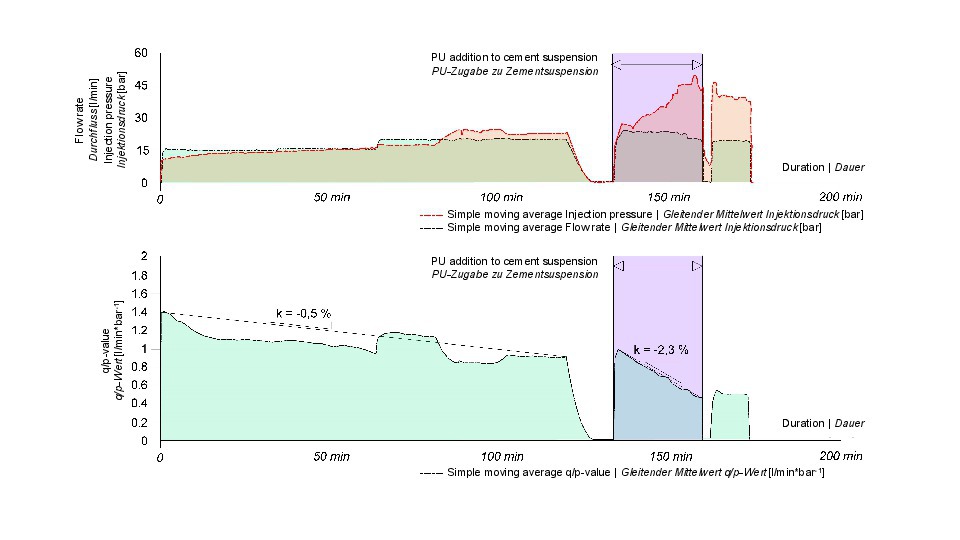

13 | Example 2 – Injection data recording of a cement-polyurethane suspension incl. a graph of the q/p value

13 | Example 2 – Injection data recording of a cement-polyurethane suspension incl. a graph of the q/p value

Credit/Quelle: H. Wannenmacher

Example 2 in Figure 13 also shows an example of pre-excavation grouting with a temporary addition of 10 % polyurethane upon exceedance of a defined volume.

After an initial drop in the q/p value, a relatively flat plateau forms with a slight increase in saturation. After reaching a defined volume limit, a polyurethane addition to the cement grouting mix was triggered. The combined cement-polyurethane grout mix’s increased viscosity leads to an immediate pressure increase and a corresponding decrease in the q/p ratio. After a defined saturation has been reached, a standard cement suspension was used again. After a defined saturation has been reached, the repeating switch towards a standard grout mix results in a horizontal plateau of the q/p value without an increase in of saturation. In this particular case, it is relatively difficult to quantify a possible reduction in grouting time through the anticipatory use of a cement-polyurethane grout mix. Nevertheless, it can be assumed that a decrease of about one hour would have been possible in this case by increased use of the cement-polyurethane grout mix and early addition of the polyurethane to avoid segregation of the cement grout mix.

The influence of cement-polyurethane grout mix on wash-out behaviour was further investigated within the framework of free discharge tests. In the free discharge test, the period or the grout volume for the complete displacement of a line filled with water is measured. Here, it is essential to assess the segregation of the grout mix until the grout mix flows entirely out of the pipe. Using pure cement grout mix, large-volume segregation with almost 100% segregation of the grout mix until complete substitution is observed. However, when using cement-polyurethane grout mixes, the segregation drops to less than 10%.

Summary and Outlook

When excavating challenging ground areas (e.g. high inflow rates and high water pressure) in tunnelling and shaft construction, pre-excavation grouting is often the method of sealing and consolidating water-bearing area. To date, cement-based or chemical grouting agents have usually been applied.

The comparatively cheap cement grouting mix has a low wash-out stability, implying that grouting success can only be achieved with a corresponding increase in time and material to compensate for wash-out effects, especially in high inflow rates and potential lateral infiltration. On the other hand, PU-based grouting materials, which guarantee a comparable better degree of sealing, are only used in emergency cases due to the high costs involved. Furthermore, stabilising additives “AWA” are only used to a limited extent due to their technically demanding handling and limited applicability in grouting technology.

The presented test results and experiences from grouting works show that cement-polyurethane-based grout mixes overcome the disadvantages of the individual base materials. Therefore, as a sum of the base materials, a grout mix with an increased field of application for the sealing of water-bearing areas in tunnelling and shaft construction could be developed. The gradual adjustment of the mix ratios allows for a constant adaptation to the grouting and thus an efficient application.