Bonding Under Pressure: Elastic Seals in a Sub-Sea Tunnel

The article describes the technical innovative supporting technologies that helped to safely drill and waterproof cross-passages under the sea in a major road tunnel project in Hong Kong, the Tuen Mun–Chek Lap Kok Link.

1 The Project

1.1 General Description

Hong Kong’s deepest, longest and largest sub-sea road tunnel, the Tuen Mun–Chek Lap Kok Link is a 5 km two-lane tunnel, which runs between the western New Territories and Lantau Island (Figs. 1 + 3). The complex work used the world’s largest tunnel boring machine (TBM) of 17,6 m in diameter and two identical mix-shield TBMs of 14 m in diameter to construct the road tunnels plus a specifically designed equipment and TBM to realize the 54 cross passages between the main twin tunnels.

Among the many challenges of this enterprise, which include the reclamation of sea areas at the start and arrival point, was the tunnel itself, running 50 m below the sea. The state-of-the-art TBMs were equipped with technical innovations which enabled real-time geological mapping of rock faces and robotic detection of damaged components on the cutterheads to reduce manual inspections under hyperbaric conditions.

Working in a compressed-air environment was the key challenge of this project. The project team had proposed to use a saturation technique for maintenance activities on the TBMs’ cutter heads. These measures eventually enhanced maximum health and safety at work for the tunnelling teams as well as overall work efficiency.

Although being in an advanced state of realization, the project is yet to be concluded, with several activities still being executed. The technical solutions mentioned in the article refer to activities that have been fully completed to date.

1.2 Special Conditions for the

Construction of the Cross-Passages

During the design phase there were concerns about the realization of 54 cross-passages by pipe jacking, as 47 of them had to be constructed under water with a design pressure of 5,5 bar.

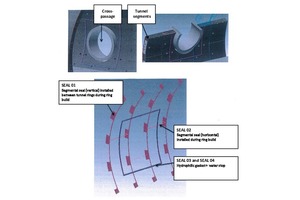

At each cross-passage, the segments of the main tunnels were designed to be cut by a small diameter TBM. The drilling itself was not an issue for the specifically designed hyperbaric small TBMs, but the eventual leakage of the segments surrounding the in- and outlets of the cross-passages due to vibration during the excavation phase needed great attention. This required a specific additional waterproofing in support of the EPDM gaskets in both horizontal and vertical joints, called SEAL 01 and SEAL 02 respectively (Fig. 4).

In the break-in area of the cross-passage TBM the project had foreseen a massive reinforced concrete “tympanum” to offer a level attack surface for the start of the TBM excavation (Figs. 2 + 5–7). The interface between concrete tympanum and main tunnel lining was then waterproofed by placing a hydrophilic gasket (SEAL 03 and 04) to prevent leakages and pressure losses. For the same reason, the break-out area in the other main tunnel was fit with a “steel bell” to ensure the to maintain the hyperbaric conditions until the entire cross-passage was finished.

1.3 Flexible Structural Seal

During the construction of the segmental rings in the main tunnels an unspecified “silicone/epoxy glue” was foreseen to be applied to the segment faces and joints (SEAL 01 and SEAL 02) to completely fill the gap between segment faces in addition to the existing segment gaskets.

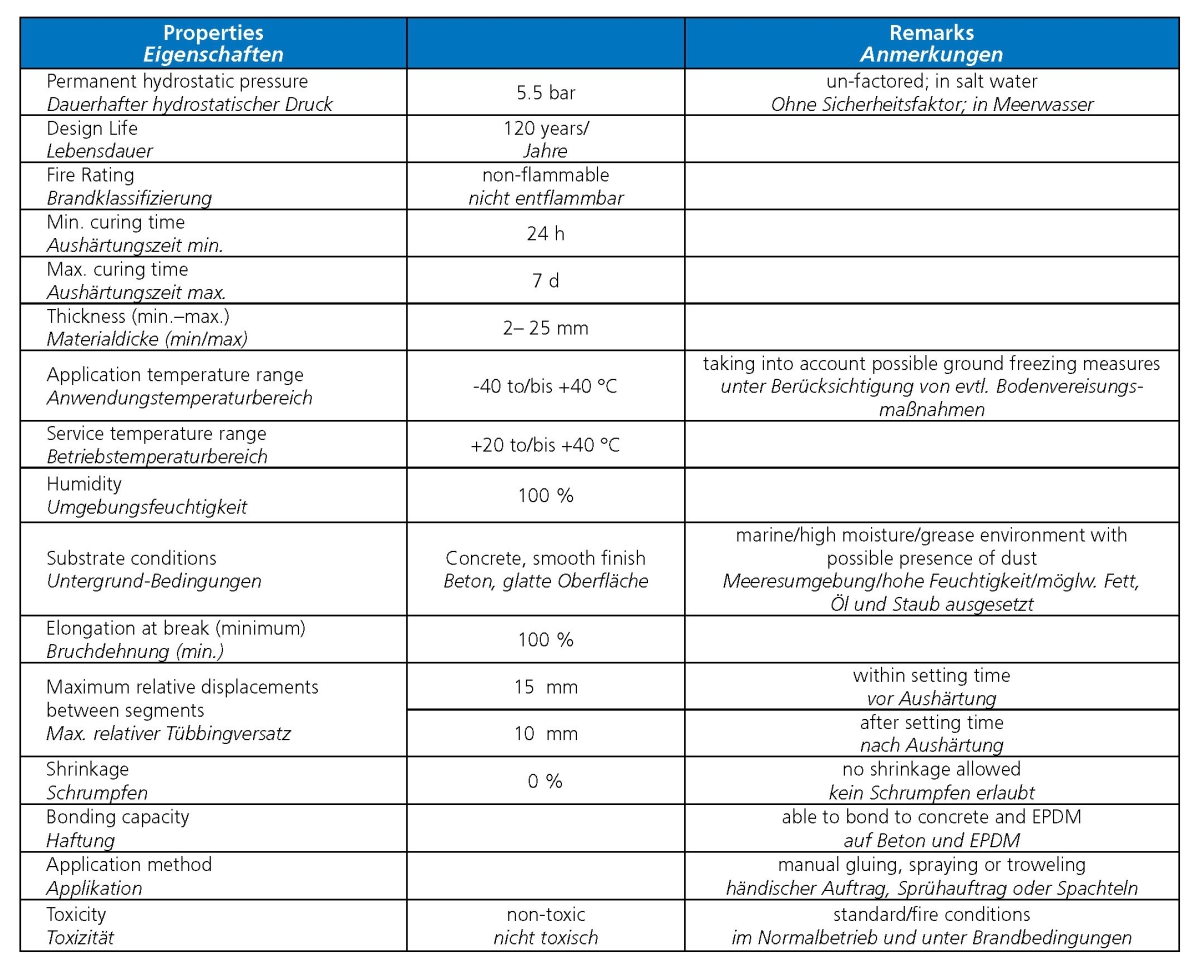

The lack of a precise definition of the material to be used for this delicate task (often simply called “the product”) obliged the technical staff of the JV to carry out a series of tests to look for the most suitable material that could meet the strict requirements for the sealant adhesive, which are listed in Table 1.

Table 1 | Requirements for the sealant/adhesive to be applied between the segments

Table 1 | Requirements for the sealant/adhesive to be applied between the segments

2 Qualifying Tests

2.1 Test Focus and Safety Factor

The search for a suitable sealant that could fulfill the required conditions was much more complex than expected. Several traditional manufacturers of construction chemicals submitted samples of products that could be up to the task. Emphasis was placed not only on the capacity of bonding well with the concrete surfaces in non-ideal conditions, but also on the integrity and bonding with the EPDM gaskets installed in the segments, to ensure a continuous sealing surface.

Originally, the design pressure had been set to 5.5 bar. But taking into account inevitable irregularities during the application under actual jobsite conditions and the dynamic vibrations of the ongoing excavation works, it was decided to apply a safety factor. Therefore, the desired achievable pressure resistance was increased to

8.5 bar.

2.2 Test Mock-Up

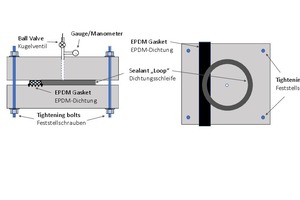

To simulate the segments a mock-up was created, consisting of two concrete blocks, roughly 50 x 50 cm squared and 10 cm thick, with an embedded EPDM gasket in between (Figs. 8 + 9).

A closed loop of sealant was placed to fully receive the water load from a centered valve while sealing the area in contact with the gasket. To simulate the segment placement the necessary pressure was applied with four bolts on the edges of the concrete blocks. Through a valve fitted with a manometer gauge it was possible to inject water under pressure inside the loop and verify its tightness.

The preparation sequence was designed to first apply the sealant ring and then tighten the blocks to press the gasket to the design pressure. The material was subsequently left to cure for one week before pressure was applied over the valve.

2.3 Test Results

After the appropriate curing time the samples from all proposed materials were put under pressure. One after the other broke between 1 and 2 bar pressure, except the one with Fix-O-Flex, a single component, SPPO-based elastic adhesive and sealant manufactured by the German company TPH Bausysteme. The material has nominal good adhesion to both concrete and EPDM and fulfills most project requirements. The sealant held up well and reached the 8.5 bar mark, while the pressure level was kept constant without noticeable pressure loss.

After the safety level had been reached, it was decided to keep increasing the pressure beyond the nominal value to verify the ultimate bursting point of the seal. It was reached at 10 bar, well beyond the required 8.5 bar and almost twice the design pressure of 5.5 bar.

3 Application in the Tunnel

In order to ensure a proper, systematic process, it was originally planned to comfortably pre-apply the sealant to the segments in the large area outside the shaft and then transport them to their assembling position in the tunnel.

However, the prevalent hot and humid climate in Hong Kong prevented the feasibility of the original plan. Since Fix-O-Flex is a single component material that reacts with moisture into a hardened rubber-like compound, there was too high a risk with this method that the sealant would reach the positioning spot already with a hardened film on its surface. This would not impede squeezing but would certainly not guarantee the bonding on the segments, thus compromising a reliable pressure sealing.

The only viable alternative was to apply the heavy-duty adhesive-sealant a few minutes before placing the segments in their definitive position. However, this solution involved working in extreme conditions, with limited space and limited freedom of movement in high temperature and humidity (Figs. 10–12).

The sealant was supplied in handy 600 ml foil sausages. Application was straight forward, using a dispensing gun to distribute an initial bead of glue in a wavy pattern on the segment’s surface and successively spreading it evenly with a toothed spatula. The treated segments were successively erected into position with the full depth of gap closed and sealed.

4 The “Bell” Sealing

To facilitate uninterrupted advancement of the huge TBM through the ventilation shaft, the project designer decided to build a temporary watertight so-called steel bell in the shaft (Fig. 13). The cylindrical steel bell was filled with water with additional equalized pressure, which allowed the TBM to efficiently advance through the shaft and break in again.

The steel bell was designed to have 11 rings of steel segments. The segment joints were sealed with TPH’s Proofmate FD System (Fig. 14), a combination of an elastic adhesive similar to Fix-O-Flex plus a reinforced EPDM membrane, placed at the intrados of the bell joints in order to fully seal the chamber and allow the advancement of the TBM under hyperbaric conditions.

5 Results and Final Considerations

A great infrastructure project needs thorough, anticipatory planning and general contractors up to the construction task. The Tuen Mun–Chek Lap Kok Link was no exception. Nevertheless, even with the best detailed planning and design, some unexpected challenges arose, some of which were really difficult to overcome. Originally only Fix-O-Flex was foreseen to the hard job of sealing off the segments, and the successful application became a reference within the tunnel jobsite. Further problems that occured around the cross-passages and the steel “bell” were solved in joint teamwork by designers, construction companies and specialized material suppliers, who also provided the proper training of the application teams on site that was necessary for a successful completion.