Redevelopment of the ceiling of the historic Metro Station

Redevelopment of the ceiling of the historic Metro Station Fehrbelliner Platz in Berlin calls for a high degree of precision. Cracks and spalling had occurred. The extremely profiled ceiling has to be renovated exactly in accordance with its original state with regard to its dimensions – as the station enjoys protected status. Redevelopment is taking place using shotcrete. The work can only be executed during the night hours when the Metro is not running.

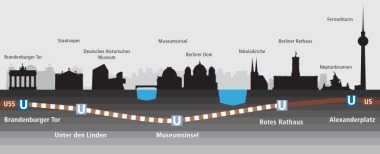

Once constructed as a branch project the present U 3 Metro line is one of the oldest in Berlin. At the beginning of the 20th century it was intended to further the growth of the Wilmersdorf district. Many of the people living there worked in the city and needed a fast and reliable transport link to reach the centre. At the same time the Berlin suburb’s attractiveness could also be furthered in this way. After all at the time the various suburbs clustered around the metropolis were competing to attract a prosperous class of citizens.

A number of historic stations along the 12 km long route still remain today and reflect Wilmersdorf’s claim to being something special. However they have become rather long in the tooth. Extensive concrete redevelopment work is being undertaken at present at the Fehrbelliner Platz Metro Station. When the city goes to sleep and the last train has gone it’s the turn of 5 teams from the Bodo Pilgrimowski Betonsanierung Company from Neuseddin, a member of the Berlin and Brandenburg Quality Protection Association for Concrete Renovation, at least for a few hours.

Although it was extensively rebuilt between 1968 and 1972 – the connection to the Line U 7 was undertaken at the time – the station, opened in 1913 in accordance with a design by the architect Wilhelm Leitgebel, still retains traces of the late-Wilhelminian period. The floor tiles as well as the wrought-iron lattice gate at the entrance are also retained in their original state just as the yellow-green tiles on the walls of the station hall finished off with a dark- brown ceramic frieze at the top. Mosaics in a majolica frame, corresponding to the style of the era, indicate to passengers the stop they just have reached. In between there are old views of the city. The octagonal central pillars faced with brown ceramic tiles are also in their original state. However the lighting units in the ceiling are new.

Special examinations of the state of the historic station revealed considerable damage to the ceiling. Cracks and spalling were already present at some places. There was evidence of cavities, which indicated flaking. On several occasions in the past major concrete spalling and cracks in the ceiling had to be repaired.

In order to ensure the station’s bearing capacity and its unrestricted use in future, a thorough renovation of the station ceiling was planned. It foresees the entire ceiling of the protected station being shored up and rebuilding it in accordance with the original concept according to the existing picture. A period of 2 years was allocated for its construction.

Situation on the Spot

The lengthy construction period is due to the circumstances on the spot: The ceiling of the Fehrbelliner Platz Metro Station is a strongly profiled beam concrete ceiling with lime cement plaster. Three-fold stepped edge joists with an overall width of some 90 cm are to be found at the sides. The central buttress axis is marked by a six-fold stepped central joist with a total width of about 1.70 m. Convex/concave ceiling panels (approx. 2.20 x 5.15 to 5.90 m) with convex/concave undersides are set up in the buttress axes. Roughly 0.90 x 1.10 m large panels are located between the buttress axes, which are framed with main and secondary joists.

As the station is located in a curve, both the convex/concave ceiling panels as well as the individual panels possess different dimensions. They have to be exactly designed to match their original state. This is particularly important on account of the lighting being reinstalled in the ceiling panels following renovation, thus requiring a great deal of formwork as shotcrete is being used. The measurements of the individual panels as well as the central, main and secondary beams had to be taken precisely and documented regarding their position and height prior to work commencing on the ceiling.

Furthermore every night prior to work starting extensive provisions have to be made in order to ensure that the irreplaceable, historic tiles in the station are not damaged. During the sand-blasting and shotcreting operations a dedusting unit is utilised, which prevents dust developing outside the given working sectors and above all to ensure the station is not polluted. It has to be dismantled again on a daily basis once work is over. The same applies to the protective covers for the electric equipment on the platform.

An additional factor is that only a period of two and a half hours is available nightly for the scheme. Operations at the station can only be carried out during the nightly break in train services between roughly 1.00 and 3.30 a.m. after the traction current has been shut down. According to company boss Bodo Pilgrimowski “we must be away from the track by 3.25 a.m. and it must not only be cleared but clean as well”.

A further difficulty is that the track is not available during certain nights because trains are still running. This represents additional, in some cases unannounced outfalls. However Pilgrimowski is full of praise: “the staff work at full speed in order to exploit the brief time available as far as possible”. At the same time, he finds there are also positive sides to the matter: “We don’t have to worry about outage quotas due to the weather. Down here we haven’t rain to bother about and the same applies to minus temperatures”.

Exact Planning

In order to exploit the time available optimally the preparatory and follow-up work is carried out outside the breaks in rail services. Towards this end an efficient equipment yard with sound-proofed enclosure was installed on the surface, which can also be operated in the night hours during noise-protected periods.

Altogether 5 teams are on the job, working from the rear towards the front. For safety reasons and to ensure that the platform area also has sufficient lighting available, first the one side and then the opposite one is redeveloped. The first team removes the concrete, the second carries out the sand-blasting operations on the beams, the third team installs the reinforcements, then the shotcreting work is executed. The team of painters finishes off the job.

Demolition Work

All loose and damaged parts of the old concrete ceiling below beam level are removed to prepare the substrate. The ceiling is largely unreinforced. Only the ceiling and joist beams are clad with wire lathing on their lower flange, which however was partially corroded.

To avoid damage occurring to the historic tile frieze the ceiling concrete is cut with positively guided equipment at the frieze edge on the peripheral joists and the central buttresses. The cutting depth amounts to 3 cm in plaster and some 7 cm in concrete. Prior to this the position of the ceiling beams was exactly identified in order to preclude damage. Demolition in the proximity of the tiles took place using small tools or by manual chiselling work.

The ceiling beams and central joist exposed in the course of the demolition work have to sand-blasted. The surface following blasting corresponds to the standard purity degree Sa 2 ½ according to DIN EN ISO 12 944. Subsequently a multi-layered corrosion protection system in keeping with 2TV KOR Steel Construction is installed: in areas where there is late contact with the concrete the corrosion protection is sand-blasted after application of the final layer in order to provide an adhesive bond. All areas where concrete is removed are also thoroughly sand-blasted to attain a workable, rough surface.

Shotcreting Operations

The production of the historic ceiling underside is carried out using shotcrete. As the existing dimensions have to be restored, the operations undertaken by the responsible contractor require the utmost precision. Prior to commencing the operations U-shaped stirrups (d = 10 mm, e = 10 cm) are attached to the ceiling beam lower flanges and the ends of the stirrups anchored in the existing concrete with chemical dowels. The central joist is also profiled and framed. The ceiling panel is provided with a stainless steel matting as reinforcement. In areas with a shallow concrete covering a 50/50/3 stainless steel reinforcement is additionally installed. Normally the layer thickness amounts to 4 cm, however on account of the generally low ceiling height in some cases a thickness of only 2 cm can be accomplished.

Subsequently shotcrete is placed in accordance with DIN 18551 with 8 mm grain size. Quality class C 25/30 concrete is applied. In this case first the reinforcement is sprayed. Then the covering layer is placed to formwork height using a sprayed mortar of quality class C 25/30 with 4 mm grain size. The formwork dimensions conform to the measurement data obtained prior to the start of construction. In this way it is ensured that the new ceiling structure remains at the height of the original one. The completed shotcrete surface is then coated with a light dispersion colour.

Summary

The repairing of the ceiling in the historic Fehrbelliner Platz Metro Station in Berlin requires exact advance planning from the responsible contractor as well as precision during execution. The work is carried out using shotcrete. After completion the ceiling corresponds both optically and in its dimensions to the original. It goes without saying that the contractor’s performance is checked by a representative of the federal body responsible for testing and supervising concrete parts as the client, the Berliner Verkehrsbetriebe demands for all its concrete renovation projects.