Massive Main Beam Machine Breaks Through at Niagara

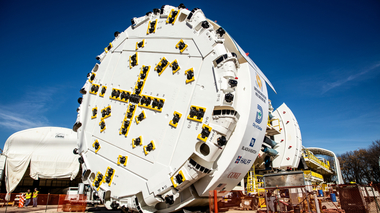

May 13, 2011 marked the completion of the world’s largest hard rock TBM drive at Canada’s Niagara Tunnel Project. A well-attended ceremony celebrated the final breakthrough of the 14.4 m diameter Main Beam machine, following an initial breakthrough into a grout tunnel on March 1 (see title).

Ontario Premier Dalton McGuinty, as well as the CEOs of project owner Ontario Power Generation and contractor Strabag AG gave speeches in front of a diverse crowd including hundreds of local tunnel workers. “We have a group of up to 500 people directly and indirectly involved with the project. Their determination, hard work, and willingness to work as one team while keeping focused to get the job done safely have all contributed to this project’s success,” said Ernst Gschnitzer, Project Manager for Strabag.

Tough Ground

The completion of the project comes after continuous highs and lows, from significant over-break to multiple world records. Poor rock conditions in Queenston shale at the beginning of the TBM drive required the tunnel alignment to be raised by 45 m into more stable rock.

While in the difficult ground, Strabag undertook significant measures to safely scale down loose rock from the tunnel crown, as loose rock was not permitted behind the final concrete lining. The unique ground support system consisted of 9 m long pipe spiles in an umbrella pattern at the crown of the tunnel. Using the new spiling method, over-break was limited to between 0.4 and 1.0 m above the normal tunnel diameter. Nearly 500 m of very difficult ground was excavated using this method, at average rates of about 3 m per day.

In addition to spiling, the new plan required removal of several structures from the TBM. These included the ring beam erector, mesh erector, TBM roof fingers, work platforms, and muck lift buckets.

The crew then installed new structures to contain over-break, including man baskets and a crown-mounted hoist for delivery of straps and mesh. A drill jumbo was added for spiling, bolting and rock scaling, while the drill controls were relocated farther back on the machine, where they would be below fully-supported sections of rock.

Record Rates

After surmounting the difficult conditions, the machine managed to achieve 2 advance rate records for any TBM 11 m in diameter or larger - 468 m in 1 month, and 153 m in 1 week, both in July 2009.

Gschnitzer cited several main reasons for the record rates: “Good design of the machine, proper maintenance, and proper operation. We proved during the drive that the machinery worked as expected, and beyond when rock conditions allowed.” He also credited strict maintenance throughout the tunnel drive, consisting of a daily maintenance shutdown lasting about 4 hours. During each shift, crew members performed an assigned task and were held to strict quality guidelines.

Kolenich added that the machine’s 20-inch diameter disc cutters may have played a role as well: “This is our first machine with 20-inch cutters. The cutters are capable of excellent excavation in very hard rock.” The larger diameter offers longer cutter life and fewer cutter changes in rock compared to 17-inch or even 19-inch cutter diameters.

From Start to Finish

“There is a sense of accomplishment here. There were logistical challenges just delivering and assembling the TBM onsite, and the machine has now overcome geologic challenges as well,” said Mike Kolenich, Robbins Manager of Projects, who followed the Niagara TBM from start to finish.

The Niagara Tunnel Project was initiated in June 2004 by provincially-owned company Ontario Power Generation. The TBM was launched in summer 2006 less than 12 months from contract signing, following Onsite First Time Assembly (OFTA). The project marked the first use of OFTA, which saves both time and money to contractors compared to factory-assembled TBMs.

While the tunnelling portion of the project has reached completion, 2 years of work still remain. Approximately 30 % of the continuous concrete lining was completed during tunnelling, with about 2/3 of the work still to be done. The finished 12.8 m diameter tunnel will be fully lined with both 600 mm thick continuously-poured concrete and a polyolefin waterproof membrane.

The concrete lining and waterproof membrane guarantee a 100-year design life for the tunnel, which will continuously experience high internal water pressure of 15 bar. The polyolefin layer was designed to prevent water from leaking out of the tunnel and into the surrounding rock, as Queenston shale swells when in contact with fresh water - a process that over time could destroy the concrete lining. The membrane was also developed for quality control, with an embedded electrically conductive layer. By applying a high voltage across the membrane, engineers can detect an opening in the membrane as small as a pinhole.

Other construction still to be completed includes the outlet structure, gates, and cofferdam, which are expected to be finished in 2013. The tunnel is planned to go into operation a year later.