Reduction of hard Rock Abrasiveness using Foam Agents

Abrasion in the case of TBM application in hard rock is a time-consuming and cost-intensive factor that can scarcely be altered.The following report describes just how this can be minimised and which tests designed to reduce wear were executed using additives.

The Department of Geology and Mineral Resources and the Department of Civil and Trans-port Engineering at the Norwegian University of Science and Technology (NTNU) have together with SINTEF Rock and Soil Mechanics co-operated for more than 40 years, when it comes to tunnelling research and engineering geology laboratory facilities. One of the main fields of co-operation is engineering geological laboratory tests and interpretation of test results. Some well known results of this cooperation are the Drilling Rate Index™ (DRI) and Cutter Life Index™ (CLI). These indices are today internationally recognised and have gained a very good reputation within the tunnelling industry, especially in the USA and in Asia for producing reliable estimates of time and cost in connection with TBM tunnelling in hard rocks. These indices have however so far not been used extensively in the more nearby market of Central Europe. One reason for this might be that weathered, jointed, sedimentary rocks and soft rocks generally speaking can provide somewhat less reliable estimates by use of the NTNU prediction models, since opening in the rocks influence the drillability more than the solid rock properties itself. The NTNU models provide good and useful information regarding tunnelling time, cost and cutter consumption for typical igneous and metamorphic hard rocks. The most recent upgrade and revision of the prediction model was done in 1998. The model was in 2007 back-calculated with TBM performance and cutter consumption from one of New York’s many tunnel projects, with good results. A new upgrade and revision of the model is planned to take place within the next years.

Reduction of abrasiveness is an interesting subject in relation to TBM tunnelling. It has as far as we know not been done any extensive studies of possible benefits that can be achieved by use of abrasion reduction additives. The purpose of this paper is to focus on some of the laboratory tests which are performed at the Engineering Geology Laboratory at NTNU/SINTEF in Trondheim, and look into some modelling of expected production rates and cutter consumption with and without the use of additives. Since 2001, some trials have been conducted at the NTNU/SINTEF laboratory in order to evaluate reduction of abrasiveness using foam agents. The testing was initiated by BASF Construction Chemicals (former MBT, today Meyco Global Underground Construction), and comprised rock material from Lötschberg Steg Adit. The tests were mainly conducted by use of a modified Nordic Ball Mill Test apparatus, but some additional testing were also performed by use of the AVS abrasion apparatus.

The modified Nordic Ball Mill Test apparatus has also been used extensively for testing of soil samples and additives in 2008. These tests were done in order to evaluate abrasiveness reduction by introducing Meyco SLF30 and ABR2 to 4 different soils.

The Nordic Ball Mill Test

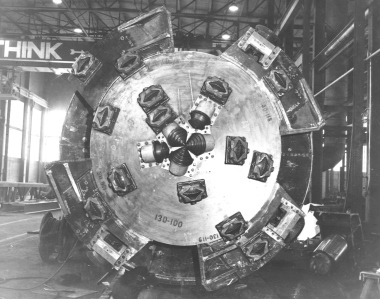

The Nordic Ball Mill Test is frequently used in Scandinavia to measure aggregate durability, hardness and abrasion resistance, especially related to wear of road surface by studded tyres (Fig. 1). The test apparatus and procedures are described in the Norwegian Standard, NS-EN 1097-9. The Nordic Ball Mill Test has a lot of similarities to the Los Angeles Abrasion apparatus, the exceptions are principally the geometry of the apparatus, the number of revo-

lutions and the quality of the materials. The Nordic Abrasion Value is according to the standard, defined as the percentage of the original sample material passing through the 2 mm sieve after 5400 revolutions at a rotation speed of 90 rpm.

The Laboratory at NTNU/SINTEF utilizes a modified version of the Nordic Ball Mill Test for determination of the abrasiveness of soils and hard rocks in connection with tunnelling. The modification of the original apparatus consists of removal of the steel ribs (originally intended to lift and drop the aggregates and steel balls) and applying a rubber lining on the inside of the steel drum. This modification is done in order to avoid steel against steel impact and wear during testing, as the measured value for the modified test is the weight loss of the steel instead of the aggregates. The Abrasion Value Ball Mill (AVBM) is defined as the weight loss in milligram of 20 cylindrical steel bits (diameter and length = 16 mm), and can hence be regarded as a direct measure of soil or rock materials abrasion or ability to induce wear on steel. The modified Ball Mill test show no measurable weight loss (AVBM = 0) of the steel bits if it is performed without soil or rock material. The Ball Mill apparatus has been used for testing of 5 different rock and soil types with different types and quantities of additives, in order to evaluate the effect of additives on the abrasiveness of geological materials. The test procedure for abrasion testing of rock or soil samples with foaming agents can briefly be described as follows.

Place 1500 g of rock or soil material in a dedicated mixer with 50 g of water and additive concentrate.

– Mix for 30 seconds on a slow speed and subsequently for 60 second on a medium speed

– Add about 10 g of water at the time and mix on medium speed until foam is generated

– Put the sample (geological material and foam) and steel bits in the rubber lined drum and secure the lid. Run the test and let it run for 1 h at 90 rpm (5400 revolutions). For Ball Mill tests, performed with 1500 g of rock or soil material, the amount of water has been from 0 to 225 g and the amount of foam agent from 0 to 25 g. Sieve analysis of the sample material has been conducted both prior and after testing for all the performed tests. The Ball Mill test has been found to be slightly influenced by the grain size distribution of the material to be tested. The general trend is that less abrasion can be expected for samples showing grain size distributions with high contents of fines. Samples with high contents of fines do also seem to be more influenced of the water content than coarser material. The influence of different water contents is shown in Fig. 2. The general trend, up to a certain level, is increasing wear by increasing water content. Fig. 3 shows average abrasion measured by testing of samples from Lötschberg Steg Adit. The testing was initiated by BASF, and the observed difference in the measured abrasion induced by water saturated rock and rock with foam, was a significant reduction for rock with anti-abrasion-additives. The experiences shown in Fig. 4. are based on findings made by Karen Klemetsrud during her master thesis work [2]. The thesis work contains laboratory testing of different additive/water ratios and soil types. It should be noted that no steel wear was recorded at any conditions for the tests performed on the “Tonstad Clay” sample. The no positive effect of additives at Vassfjell silt can be related to the relative fine grain size in this material. By adding water and additives, it is believed that the silt cemented into larger lumps that causes higher kinetic energy in contact with steel, hence higher wear. However by increasing the additive/water ratio some reduction of wear is experienced as shown in Fig. 5. From general tribology a dry material in contact with steel gives in general a lower expected abrasive wear. The reason is that fines from the crushed material acts as a protective cushion around the steel surface, and the steel itself will be in less contact with the other material. In TBM hard rock tunnelling excavation without water is unthinkable with regards to wear and breakdowns of cutters and support structures due to overheating, followed by severe dust problems. The Ball Mill test showed promising results for reduction of the abrasion by use of additives for both hard rock and for soil samples.

The AVS test and the Soil Abrasion Test (SAT)

The Abrasion Value (AV) apparatus showed in Fig. 6 was developed at the Department of Geology NTNU in 1958 [3]. The AV test is used to determine a measure of a rock’s ability to induce wear on tungsten carbide. A further development introduced the Abrasion Value Cutter Steel (AVS) which provides a measure of a rock’s ability to induce wear on cutter ring steel. NTNU/SINTEF has currently tested some 1900 hard rock samples from 50 countries and 150 soil samples from 4 countries, in order to determine the abrasion properties for commercial wear estimation and research.

The AVS is performed by use of crushed rock powder <1.0 mm, while the SAT is performed by use of the sieved portion of soil samples <4.0 mm. The AVS and SAT are both defined as the weight loss of the cutter ring steel test piece in mg after 1 minute of testing. The AVS and SAT tests are normally performed on 2 to 4 test pieces. The abrasion powder for these tests is prepared by a representative and homogenized sample material, and the variation is hence found to be very low. The variation shall not exceed 5 units (mg of weight loss) per sample. The reported AVS and SAT values are reported as the mean value of 2 to 4 parallel tests.

The AVS and SAT tests are always conducted on dry material. Some experimental tests have been performed with use of additives at moist conditions. The measured reduction of the abrasiveness by applying foam showed a significant difference, with a substantial reduction of the measured wear. According to Fig. 7, the measured AVS value for a sample of untreated rock material was found to be 25, which is classified as medium to high abrasiveness according to Table 1. Adding ABR type 1 gave an AVS value of 9.5 which is classified as low abrasiveness and adding of ABR type 2 gave an AVS value of 4.0, which is classified as very low to low. For comparison AVS values for quartzite are generally between 44 and 70, and for limestone typically between 0.5 and 3.0. The observed reductions of the AVS values, by introduction of anti-abrasion agents, are more significant than the reductions that were obtained by the Ball Mill apparatus The most energetic reason for this is likely the relative high amounts of additive used. The additive was applied manually by a hand operated pump, and the exact amount of foam was not controlled.

NTNU/SINTEF has recently constructed a new updated AV, AVS and SAT apparatus, which will enable measurement and recordings of the friction during testing. One of the purposes by the new apparatus are further testing of rock and soil material with foam additives, and hence also for evaluation of the friction with and without foam. Theoretically this might give an indication of energy requirements of different rock excavations. Variable rpm for the rotating disc and adjustment of the applied weight on the test piece are other features which will provide possibilities for further research and development.

Impact of anti-abrasion-additives on TBM performance and economy

Meyco ABR5 anti-abrasion and anti-dust agent has been used on the Guadarrama High Speed Railway Project in Spain. A 9.46 m diameter doubleshield machine used some 600 t of ABR5, boring through rock types showing UCS of up to 280 MPa. These rocks showed quartz contents of up to 80 % and measured Cerchar Abrasivity Index values between 5 and 6, classified as extremely abrasive to quartzitic. The following benefits associated with the use of agents were according to BASF Construction Chemicals [1]:

– Cutter wear reduction of >15 % resulting in 25 to 30 h/month less down time due to cutter changes

– Clean cutter tools with a temperature decrease from 90 to 150° C to below 70° C, resulting in shorter down time due to less cooling and less cleaning

– Improved muck transfer and a dust free working environment resulting in better working conditions

– Reduction of water usage and less water reclamation.

The use of Meyco ABR5 does however require some minor changes and modifications of the TBM. The agents must be supplied to the cutter head as foam. A foam generator is hence needed in order to make it possible to inject the foam through nozzles on the TBM cutterhead. Additio-nally, a rotary coupling is also needed for a TBM diameter >4 m.

Key assumptions made for a roughly estimated benefit calculation:

– TBM speed of around 50 mm/minute – monthly advance rate of 500 m

– fixed TBM costs around 2000 Euro/h.

With 70 000 Euro ABR5 monthly product costs it was possible to reduce the wear & maintenance in this case of more than 15 %, which can be back-calculated to a reduction of maintenance and material costs of more than 50 000 Euro. But the reduction of maintenance has not only an influence on the costs: it realises also considerable time savings. The 15 % of reduced downtime can directly be translated into 80 to 90 m of extra excavation per month – turning the above calculation with an initial loss of 20 000 Euro into final savings of some 40 000 Euro per month.

Furthermore, important be-nefits such as a nearly dust free environment, more convenient and quicker changing of discs (due to lower temperature and clean discs), drastic reduction of sprinkling water and reduced energy consumption due to less exhausting are even not taken into consideration with the above benefit calculation – but do have a significant influence in many project costs.

The NTNU model for estimation of tunnelling advance and expected cutter life has been used to estimate the impact of ABR5 theoretically. Cutter Life Indices (CLI™) have been calculated by assuming that the abrasion is reduced as presented in Fig. 5. A higher CLI™ value indicates longer cutter life and less down time due to cutter changes, thus higher expected advance rates. The cost of ABR5 per tunnel metre is approx. 125 to 250 Euro. The modelling is based on the software FullProf [4] which uses recorded information of performance rates and cutter consumption for TBM projects related to several combined geological parameters.

Conclusion

Based on the findings of the conducted laboratory analyses, the field study of the Guadarrama Project and the cost–benefit analysis presented in this article, the use of abrasion reducing additives show a very good potential as an achievable cost reduction. It should hence be con-

sidered as an important aid for beneficial project cost savings, in connection with abrasive ground condition tunnelling.

By introducing anti-abrasion additives in laboratory testing, the measured abrasion is significantly reduced compared to the wet conditions. The laboratory testing does also show that the achieved results are dependent on test method used and the ratio of anti-abrasion agent and water. In order to get more field experience and data on this subject BASF, SINTEF and the Norwegian University of Science and Technology is currently planning to test anti-abrasion additives at a tunnel under excavation, coping with highly abrasive and hard rock conditions. The study, which will be executed in close cooperation with an acknowledged TBM machine manufacturer, is planned to be conducted during 2009 and 2010.