Tunnel Boring Machine Delivered for Elbe River Crossing of SuedLink

The grid expansion project SuedLink of the two transmission system operators TenneT and TransnetBW will transport electricity over 700 km from Brunsbüttel in Schleswig-Holstein, northern Germany, to Großgartach in Baden-Württemberg, southern Germany, once completed. This will also involve crossing under the Elbe River with a tunnel around 5.2 km long. The machine technology for the ElbX section comes from Herrenknecht and was handed over to the network operators and the JV Tunnel ElbX (Porr and Wayss & Freytag), in July 2024.

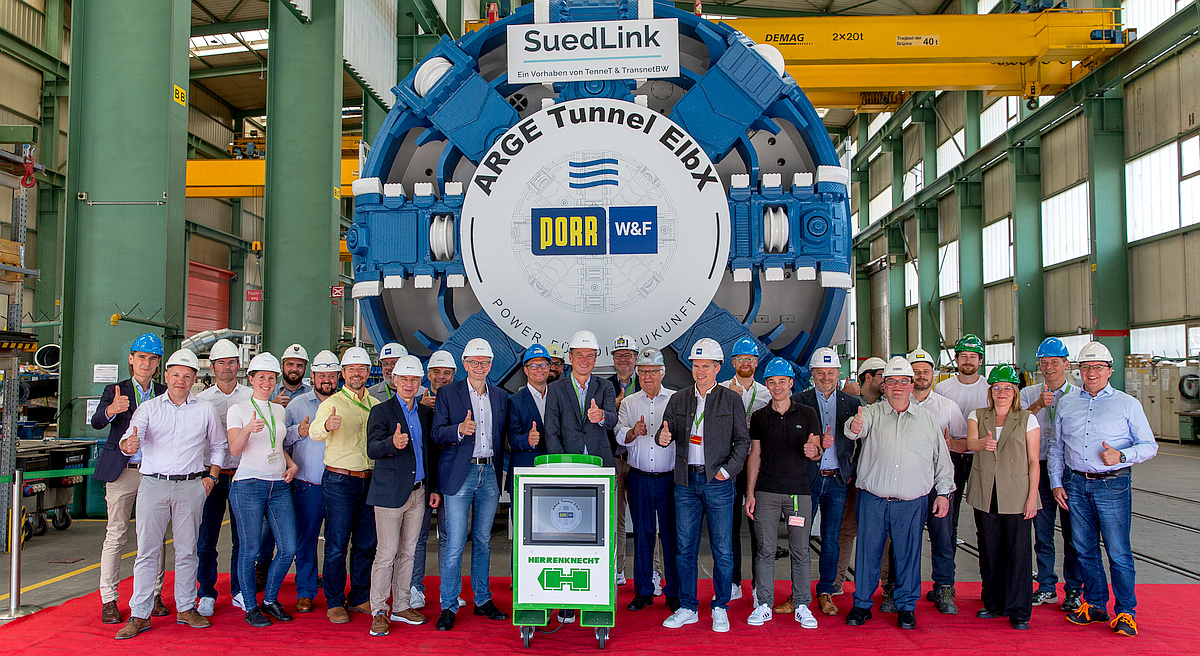

Factory acceptance of the tunnel boring machine with representatives of ARGE Tunnel ElbX (PORR GmbH & Co. KGaA and Wayss & Freytag Ingenieurbau AG), the grid operator TenneT TSO GmbH and Herrenknecht AG

Factory acceptance of the tunnel boring machine with representatives of ARGE Tunnel ElbX (PORR GmbH & Co. KGaA and Wayss & Freytag Ingenieurbau AG), the grid operator TenneT TSO GmbH and Herrenknecht AG

Credit/Quelle: Herrenknecht AG

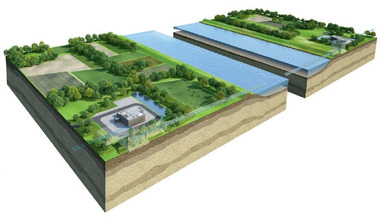

SuedLink is one of several extra-high-voltage direct current (HVDC) transmission lines planned in Germany. The “electricity highway” is intended to connect the wind power regions of northern Germany with the industrial locations of Bavaria and Baden-Württemberg in southern Germany. For this to succeed, the first step is to cross under the Elbe River. This section is considered a key project for the underground cable line. The consortium Tunnel ElbX, is building an approximately 5.2 km long tunnel from Wewelsfleth (Schleswig-Holstein) to Wischhafen (Lower Saxony) on behalf of the transmission system operator TenneT. The tunnel will accommodate six 525 kV underground cables and the associated building, safety, control and monitoring technology as well as rails for the tunnel vehicles required for maintenance and repairs.

Mixshield Drive 20 Meters Below the Elbe River

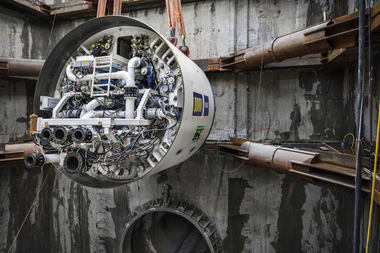

Herrenknecht AG has received an order from ARGE Tunnel ElbX, consisting of Porr GmbH & Co. KGaA and Wayss & Freytag Ingenieurbau AG, for a tunnel boring machine (TBM) specially designed to meet the project requirements. On its way under the Elbe River, it will encounter varied geology consisting of clay, peat, sand, gravel as well as stones and boulders. The Mixshield TBM has a diameter of 4900 mm is 190 m long and weighs a total of 700 t. Johannes Faißt, Project Manager at Herrenknecht, explains: “The ElbX tunnel with its heterogeneous subsoil, high water permeability and the water pressure under the Elbe is a special challenge that spurs us and our technologies on.”

The highly complex Mixshield, a Herrenknecht development, is sealed against the water pressure 20 m below the Elbe with a multiple sealing system. The TBM is not only digging the tunnel but is also lining it at the same time with prefabricated concrete segments. The tunnel will have an inner diameter of 4 m and an outer diameter of 4.60 m.

Tunnelling To Begin at the End of 2024

After factory acceptance, the machine will be dismantled, transported to Schleswig-Holstein, lifted into the shaft excavation pit in individual parts and assembled. The TBM is due to start work towards the end of the year.