Replacement of Emergency Doors in the Great Belt Tunnel

Elkuch‘s newly developed emergency door will be installed in the 31 cross passages of the Danish Great Belt Tunnel by the end of 2023

Elkuch‘s newly developed emergency door will be installed in the 31 cross passages of the Danish Great Belt Tunnel by the end of 2023

Credit/Quelle: Elkuch Group

The Swiss Elkuch Group has been awarded with the replacement of emergency doors in the Great Belt Tunnel (Storebælttunnelen) in Denmark by Sund & Bælt Holding A/S. The two tubes of the Great Belt Railway Tunnel are each 8024 m long and run at a depth of up to 40 m below the seabed. The two tunnels, one for each direction of travel between the island of Sprogø and the town of Korsør (Zealand), are connected every 250 m by cross-passages.

Installation of 61 New Fire-Resistant Door Sets Until December 2023

The required scope of work consists of the dismantling of the existing emergency escape doors and the manufacturing and installation of 61 new fire-resistant door sets within a narrow time window. The project is scheduled to be completed until December 2023. Sund & Bælt Holding A/S, acting as the responsible public operator, aims at the fastest possible resumption of daily operation of the railway tunnels.

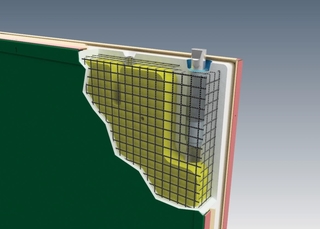

For the successful implementation of the project, it is crucial that the work meets the highest quality standards regarding the required specifications and functionality of the doors. Here, a new development of the Elkuch Group is implemented, with which the high technical requirements on the construction site are to be fulfilled and an on-time installation is to be ensured. The door leaf consists of a fire-resistant composite core with rock wool insulation. The load-bearing composite structure is reinforced with carbon fiber mesh. Due to these features, a three-point suspension can be realized.

A cross-section through the design of the door with reinforcement and rock wool core

A cross-section through the design of the door with reinforcement and rock wool core

Credit/Quelle: Elkuch Group

Low Deformation in the Event of a Fire

This combination ensures a very high rigidity and low deformation in the event of a fire while at the same time offering high resistance to fatigue load, and it prevents jamming or tension of the door. The special manufacturing process enables an airtight, indivisible door leaf with firmly anchored hinge and bolt guides. At the same time, the weight of the door leaf is no higher than that of a conventional steel construction. The panic bar is sealed on both sides with rubber gaiters. The door locking bolt is spring loaded and located on top, sealed with a scrapper. The locking system can be accessed by removing a cover with three reusable gaskets. The sealing is mounted on the door leaf on all four sides. It will be made of polyester for long durability. All seals can be changed without removing the door leaf from the frame.

Emphasis Also on Minimising Maintenance Requirements

The door was designed with a focus on minimal maintenance effort for the customer. Only routine checks are to ensure that the operating forces are within the defined limits and the self-closing function works correctly. These features lead to optimised cost control for the tunnel operator.