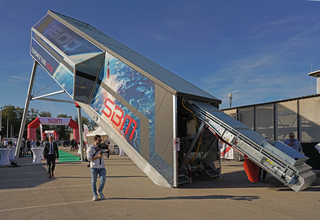

Premiere of the New SBM Euromix 1600 Nova Mobile Concrete Mixing Plant at bauma 2025

In mid-October 2024, SBM Mineral Processing unveiled the new SBM Euromix 1600 Nova mobile concrete mixing plant at its headquarters in Oberweis, Upper Austria. With a production capacity of up to 80 m³/h of hardened concrete, it replaces the previous entry-level model in the Euromix range. Important cornerstones of the concept are a high degree of operator comfort and safety combined with high efficiency in year-round operation.

Euromix Range Comprises Seven Models

The SBM Euromix 1600 Nova mobile concrete mixing plant will be showcased publicly for the first time at bauma 2025 in Munich

The SBM Euromix 1600 Nova mobile concrete mixing plant will be showcased publicly for the first time at bauma 2025 in Munich

Credit/Quelle: SBM Mineral Processing

Mobile or easily relocatable concrete mixing plants have been standard equipment for years in tunnel, airport and highway construction, as well as on large industrial construction sites. For over 25 years, SBM Mineral Processing has been successful worldwide with its Euromix series in the premium segment of mobile and super-mobile mixing plants. According to the manufacturer, several hundred plants are in operation with customers including major international groups, national or regional construction companies and highly specialised concrete service providers with single fleets of up to 20 units. High-quality mixing and batching technology, as well as modular, expandable aggregate hoppers and binder silos, cover all modern concrete applications, including recycling or special concretes. Current references in the field of tunnel construction include the Fehmarnbelt Tunnel between Denmark and Germany, the 2nd main line of the Munich S-Bahn and the FAIR particle accelerator facility in Darmstadt.

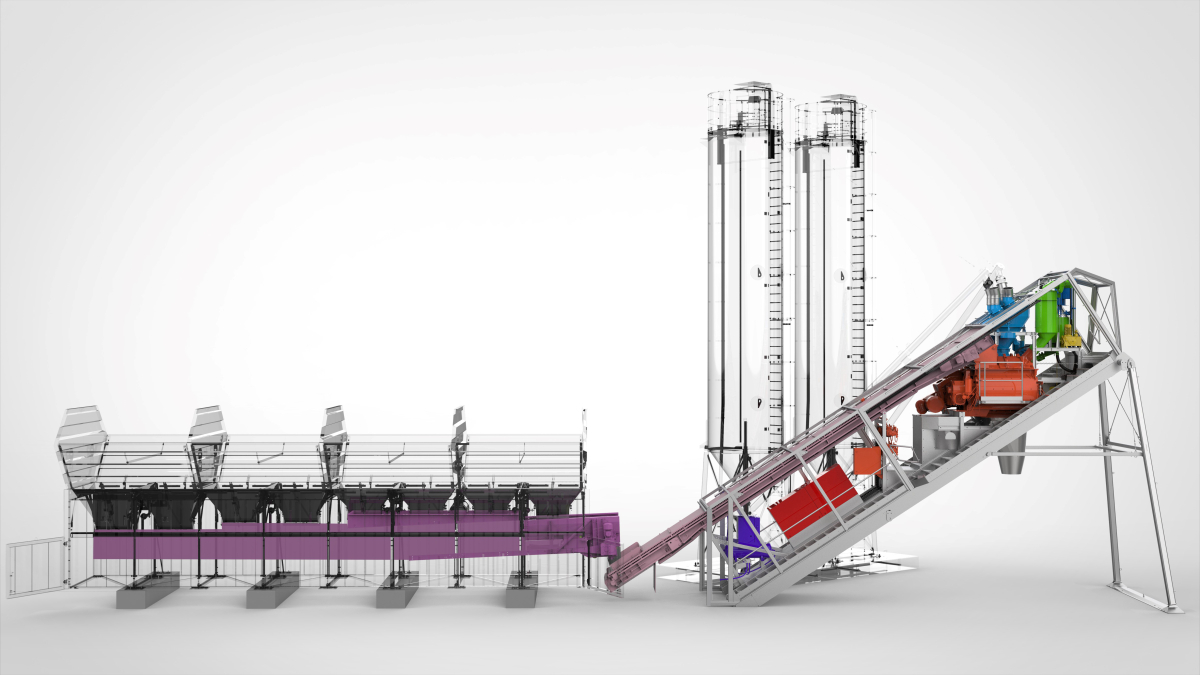

The Euromix range comprises a total of seven models: five solo versions with mixer sizes from 1.67 to 4.00 m³/batch of hardened concrete output and hourly outputs from 80 to 175 m³, as well as two “Duo” models, which are designed as a plant combination for high-capacity mass concrete production (2 x 3.0 m³/batch; 230 m³/h resp. 2 x 4.0 m³/batch; 300 m³/h). The Euromix 3300 Space 145 m³/h super-mobile plant, launched five years ago, has been particularly successful on the market. With optimisations in space utilisation and maintenance access, it set important trends in technical development.

Optimised Compact Class

With the new Euromix 1600 Nova, SBM is now bringing these advantages to its smallest plant class. The model 1600 has been in the range since 2007 and is aimed at small to medium-sized construction sites with a daily requirement of up to 800 m³ of hardened concrete or liquid soils for backfilling. The mixer unit, hopper and binder silos are transported on flatbed trailers. On site, a mobile crane and 2–3 employees are usually sufficient to erect the entire plant on a sufficiently compacted base and have it ready for operation within one day.

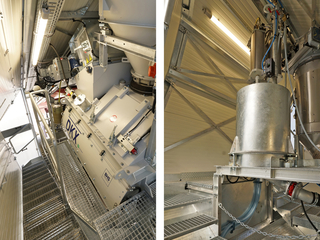

The manufacturer promises 100 per cent more space and therefore significantly improved accessibility for the Euromix 1600 Nova

The manufacturer promises 100 per cent more space and therefore significantly improved accessibility for the Euromix 1600 Nova

Credit/Quelle: SBM Mineral Processing

The manufacturer promises 100 per cent more space and therefore significantly improved accessibility for the Euromix 1600 Nova, thanks to the new basic design of the mixer unit and the superstructure made of 40 mm isopanels with fully integrated extensions on both sides in the upper area, developed in collaboration with industrial designers. Safe stairways and enlarged maintenance platforms make the mixer and all weighing and batching equipment for water, cement and additives easily accessible from all sides. While the closed superstructure with fully insulated roof area already enables energy savings in normal operation, an optional winter package with additional floor insulation, interior heating and enclosure of the rock transfer area makes operation safe and economical even at low temperatures of +5°C and below.

The fully integrated mixing unit significantly reduces set-up times and makes the production process largely independent of weather conditions

The fully integrated mixing unit significantly reduces set-up times and makes the production process largely independent of weather conditions

Credit/Quelle: SBM Mineral Processing

Fully Integrated Technology

The heart of the Euromix 1600 Nova is still the BHS DKX 1.67 twin-shaft mixer with an hourly output of up to 80 m³ of hardened concrete. A newly developed SBM high-pressure cleaning system is also incorporated. In addition to almost complete batching technology (only the aggregates are weighed externally via the belt feeder in the hopper unit) a compressor, optionally with refrigerated air dryer, is now integrated in the mixer unit. Standardised plug connections for the electrical equipment make installation quick and safe. The Nova generation is also fully compatible with the customers’ preferred control system – all common systems can be easily integrated.

The new system’s more flexible installation options also offer significant advantages in terms of site organisation. The hopper units, with a choice of 4 or up to 8 chambers (storage volume: 64/256 m³), can also be positioned at a 90 degree angle to the Nova mixer unit. This allows the best use to be made of even the smallest installation space and, above all, better separation of wheel loader loading and transport mixer traffic. The redesigned front central support of the mixer unit ensures a smooth approach to the mixer discharge from three sides, making plant operation highly efficient and safe even with a small number of personnel (mixing foreman + wheel loader operator).

SBM at bauma 2025

Sales of the Euromix 1600 Nova has already started – the new plant will celebrate its official world premiere on the SBM stand at bauma from 7–13 April 2025 in Munich, Germany (Stand: Hall B2.249; Courtyard B2/B3).